Characterization of Ash from Tropical Biomass Gasification for Soil Fertilization

David Gildas Farid Adamon1

*

, Djonoumawou Mèmèvêgni Grâce Floriane Chidikofan2

, Djonoumawou Mèmèvêgni Grâce Floriane Chidikofan2

, Charbel Kinzo1

, Charbel Kinzo1

and Gloire Aviansou1

and Gloire Aviansou1

1

Department of Energy,

National Institute of Industrial Technology of the National University of Sciences,

Technologies, Engineering and Mathematics of Abomey,

(INSTI/UNSTIM),

Republic of Benin

2

National School of Energy Engineering and Processes of the National University of Sciences,

Technologies, Engineering and Mathematics of Abomey,

(ENSGEP/UNSTIM),

Abomey,

Republic of Benin

Corresponding author Email: adamon.farid16@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.19.2.18

Copy the following to cite this article:

Adamon D. G. F, Chidikofan D. M. G. F, Kinzo C, Aviansou G. Characterization of Ash from Tropical Biomass Gasification for Soil Fertilization. Curr World Environ 2024;19(2). DOI:http://dx.doi.org/10.12944/CWE.19.2.18

Copy the following to cite this URL:

Adamon D. G. F, Chidikofan D. M. G. F, Kinzo C, Aviansou G. Characterization of Ash from Tropical Biomass Gasification for Soil Fertilization. Curr World Environ 2024;19(2).

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2024-03-18 |

|---|---|

| Accepted: | 2024-07-08 |

| Reviewed by: |

Praveen Kumar

Praveen Kumar

|

| Second Review by: |

Fadly H. Yusran

Fadly H. Yusran

|

| Final Approval by: | Dr. R K Aggarwal |

Introduction

Given the scarcity of fossil fuels and the negative impact of greenhouse gases on the environment, biomass has received increasing attention in recent years. It is potentially CO2-neutral and renewable energy source1-2.

Waste-to-energy is highly favored due to the potential for cost savings in fuel transportation and the possibility of using biomass resources with minimal commercial value3. Biomass resources come in several forms: (i) waste from the plant kingdom/agricultural residues; (ii) waste from the animal kingdom; (iii) waste from agri-food structures; (iv) waste from aquatic sources; and (v) organic waste from communities and even industrial waste in addition to animal waste4.

Gasification technologies have developed rapidly and demonstrated their potential as a solution for the production of fuel gas and thermal energy in rural areas where agricultural waste (rice husks, groundnut hulls, cotton stalks, corn cobs, etc.) is abundant5-7.

In this context, Benin through the Government Action Plan (PAG 2016-2021: 45 Flagship Projects) has decided to invest in the field of renewable energies by focusing on the organization of the biomass-energy sector, in particular agricultural residues. The “Biomass Energy” project aims to install gasification power plants in four municipalities in the country, municipalities with abundant agricultural residues, for a total capacity of 15 MW.

Gasification equipment, some of which is commercially available in varying power ranges, can be used to convert biomass into electricity through cogeneration8.

During the thermochemical degradation of biomass, the non-combustible inorganic constituents of which it is composed remain in the form of ash residues. The ash content of woody waste is generally low, while it is relatively high in agricultural residues (case of rice husks: above 20%).

The growing consumption of biomass in energy applications is generating increasing quantities of ash. Its storage and disposal in landfill sites is costly and results in the loss of valuable resources 10. It is important to recover these large quantities of ashes in connection with environmental protection; In doing so, jobs could be created4.

There are three main categories of use of ashes11-12-13: (1) Use as fuel in ovens; (2) Use in construction. Ashes can finally be used as a substitute for cement in concrete. However, it should be noted that most biomass-derived fly ashes cannot fulfill the specifications required for this application. (3) in the agricultural field: they are used as organic fertilizer (3) Use in agriculture: directly as organic fertilizer.

The ash essentially contains the following elements: Ca, Si, Al, Mg, Na, K, S, Fe, P and Mn. In this context, the ashes coming from the thermochemical valorization of agricultural biomass possess several types of nutrients: Mg, B, Ca and K etc.14-15. Some of these elements (Zn, Fe, Cu, etc.) are classified as essential trace elements for plants, while others are essential for the metabolic pathways of photosynthesis. However, ashes contain heavy metals which negatively impact the quality of agricultural soils and the environment: this is also the case when they are infiltrated into groundwater and surface water16-17.

Since ashes do not have the same properties due to the nature of the biomass and the process leading to their generation, it is unlikely that these ashes will be valued in the same way.9. According to Demirbas18, the composition of the ashes is closely linked to the nature of the plant species, the growing conditions and the nature of the processes. Before considering land application, ash from any biomass source must be carefully analyzed. Knowledge of the physicochemical properties of the ashes will make it possible to identify the appropriate type of recovery9. Particularly, there is a gap in the knowledge regarding the physicochemical properties of by-products derived from the gasification of different biomasses.

The present study aims to answer this concern through the performance of gasification tests on a pilot system with four (4) types of biomasses and comparative analyses of the chemical properties of their residual ashes in the laboratory.

Materials and Methods

Biomass gasification plant and sampling of ash

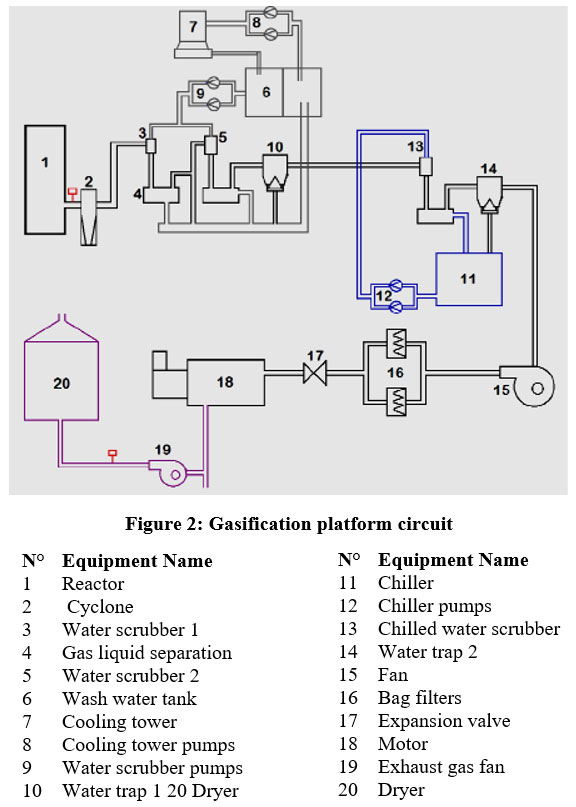

Located in the town of Porto-Novo in Benin, the co-current fixed bed gasifier, the subject of this study, was designed and manufactured in India by the company ONV BIO and the Indian Institute of Science (IISc) Bangalore (Figure 1). It is equipped with a gas mixture purification system, which includes a cyclone, two sprayers, a water purifier and a filter operating in series. (Figure 2). Due to the shape of the cyclone and the gas outlet pressure of the reactor, heavy particles in the gas fall by gravity and collect in the cyclone hopper. After several processing operations, the syngas are transported to the electric current generator.

| Figure 1: Biomass gasification plant of Songhaï Center located in Porto-Novo, Benin

|

The ash samples analyzed came from two locations: at the bottom of the gasifier reactor (S1) and at the cyclone separator (S2). These are depicted in Figure 2, which illustrates the gasification system.

| Figure 2: Diagram flow of biomass gasification plant

|

Table 1 outlines the operational conditions associated with gasification and provides details regarding the sampling locations for ash.

Table 1: Experimental conditions

Operating conditions of gasification | Description |

Biomass feeding rate | 20-35 kg. h-1 |

Gasification agent | Air |

Reduction temperature | 700-800 °C |

Ash sampling points | Temperature experience of gas phase around each point |

Gasifier Reactor bottom S1 | 400-600 °C |

Cyclone bottom S2 | 150-250 °C |

For each biomass, the tests were conducted in triplicate. Ash samples are taken during maintenance after the entire system has cooled down. Each sample taken is labeled, combining the code assigned to each biomass and the ash recovery point code (Figure 3).

| Figure 3: Ash sample and labeled.

|

Gasification feedstock and preparation for the tests

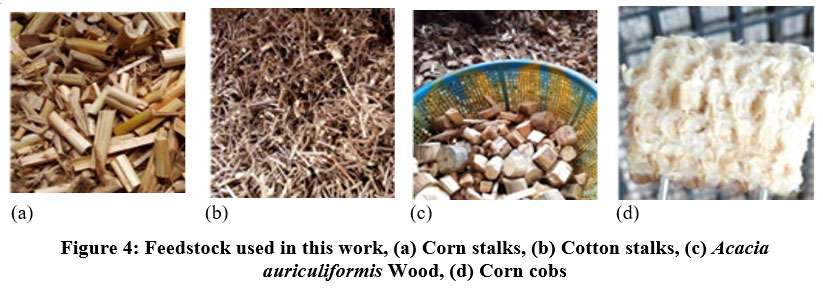

The raw materials used for the gasification tests in this study are corn stalks and cobs, cotton stalks, and Acacia auriculiformis wood (Figure 4).

The agricultural sector is a significant contributor to the national economy of Benin, accounting for 27% of the country's GDP in 2021. A study of ten agricultural seasons revealed that corn and cotton are the leading crops in terms of production 19, which justifies the selection of these materials. For the 2017-2018 crop year, the quantities of maize and cotton residues produced are presented in Table 2.

Table 2: Quantity of maize and cotton residues produced for the 2017-2018 crop year

Agricultural product | Waste or by-products | Quantity of product (ton) | Residues/product ratio | Quantity of residues (ton) | Total (ton) |

Maize | Cobs | 1 600 000 | 1 | 1 600 000 | 6 400 000 |

Stalks and leaf | 3 | 4 800 000 | |||

Cotton | Stalks and cobs | 597 986 | 2,7 | 1 614 562 | 2 391 944 |

Shells | 0,3 | 179 396 | |||

Linter | 1 | 597 986 |

Acacia auriculiformis is a dedicated crop with high energy potential that is produced and used on the experimental site.

The physicochemical properties of the biomasses studied vary depending on whether it is the content of cellulose, hemicellulose, lignin, or the level of ash, volatile matter and fixed carbon.

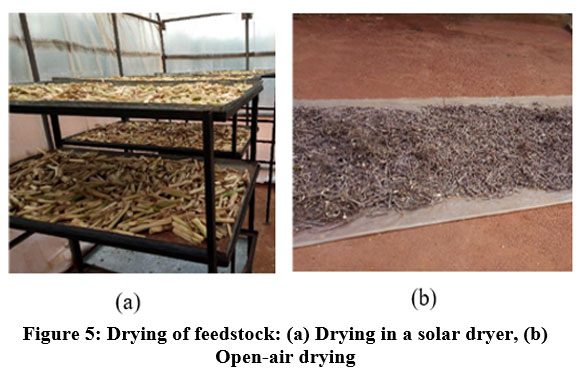

Agricultural biomass was collected from fields in the commune of Parakou in northern Benin after harvest and transported to the gasification station. All samples underwent pre-treatment, which involved removing bulky leaves and branches20-21-22.

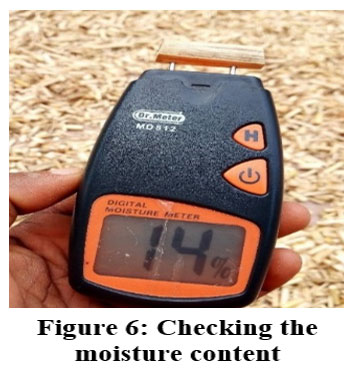

They were then cut into particles approximately 3cm x 3cm x 3cm in size and dried to achieve a humidity level below 15%. Drying was carried out using both open-air and solar drying methods (Figure 5). The humidity level was checked with a meter before each gasification test (Figure 6).

| Figure 4: Feedstock used in this work, (a) Corn stalks, (b) Cotton stalks, (c) Acacia auriculiformis Wood, (d) Corn cobs

|

| Figure 5: Drying of feedstock: (a) Drying in a solar dryer, (b) Open-air drying

|

| Figure 6: Checking the moisture content

|

Ash characterization method

The analyses were carried out at the Laboratory to Support the Improvement of Soil Health, Water Quality, and Environmental Protection (2A2S2E) of the Agricultural Research Institute of Benin (INRAB).

Ash content

It is obtained by taking the ratio between the mass of ash obtained after incineration and the mass of the incinerated sample.

Carbon content

The quantity of organic matter is determined by making the difference between the mass of the sample incinerated and the mass of the ashes obtained after incineration. The carbon content is determined by considering the empirical coefficient of 2 which assumes that the (quasi-crude) organic matter contains 50% carbon 23.

Silica and metals content

The ash is dissolved in 5 cc of HCl, 6 N which is evaporated on a hot plate at 125 °C. The viscous residue obtained is recovered in 0.1 M HNO3 and then filtered on ash-free paper in a 100 cc flask. The insoluble fraction is incinerated in the oven then reprocessed as before. The remainder recovered using the ashless paper is quantified and roughly corresponds to the siliceous fraction insoluble in acids. The solution thus obtained by successive filtrations is used to determine the metals by Atomic Absorption Spectrophotometry (AAS) or by Molecular Absorption Spectrophotometry (colorimetry). To minimize the effect of ionic interference during the absorption process, it is added to assay extracts of specific reagents. Thus, for the dosage of Ca and/or Mg, Lanthanum at 10 g L-1 is used. For the dosage of sodium and/or potassium, the extracts are added with CsCl at 2 g L-1.

Total phosphorus

The extract obtained above is subjected to the hot action of ammonium molybdate and ascorbic acid. This action develops a blue-colored complex around P, which can be measured by colorimetry to determine the concentration of this metallic element.

Results and discussion

The chemical analyses of the ash samples from Acacia auriculiformis wood, corn cobs, corn stalks, and cotton stalks have yielded the following results (Table 3). The values shown for each parameter are averages calculated from the data from the three trials carried out.

Table 3: Nutrient and heavy metal concentrations in Gasifier Reactor and cyclone bottom ashes produced from four biomasses.

Elements | Acacia auriculiformis Wood | Corn cobs | Corn stalks | Cotton stalks | ||||

|---|---|---|---|---|---|---|---|---|

S2-cyclone bottom | S1- Gasifier Reactor bottom | S2-cyclone bottom | S1- Gasifier Reactor bottom | S2-cyclone bottom | S1- Gasifier Reactor bottom | S2-cyclone bottom | S1- Gasifier Reactor bottom | |

Si % | 3.33 | 9.67 | 3.59 | 11.37 | 3.53 | 11.47 | 3.95 | 4.39 |

Ca % | 20.28 | 12.67 | 22.56 | 8.49 | 21.73 | 6.91 | 19.96 | 13.18 |

Mg % | 1.25 | 1.46 | 1.19 | 0.97 | 1.21 | 1.36 | 1.19 | 2.12 |

K % | 2.58 | 3.82 | 2.41 | 2.14 | 2.58 | 7.57 | 2.99 | 11.09 |

Na % | 0.69 | 1.17 | 0.91 | 0.86 | 0.91 | 0.82 | 1.41 | 0.75 |

P % | 0.82 | 1.21 | 0.61 | 0.73 | 0.69 | 2.15 | 0.57 | 2.16 |

Fe % | 2.79 | 15.27 | 2.329 | 18.46 | 3.143 | 19.53 | 5.45 | 10.31 |

Mn mg kg-1 | 873.94 | 2004.23 | 1006.94 | 2408.54 | 1066.11 | 2532.25 | 1248.8 | 2232.77 |

Cu mg kg-1 | 114.21 | 155.71 | 103.56 | 237.89 | 116.84 | 123.12 | 113.15 | 227.46 |

Zn mg kg-1 | 3231.93 | 523.99 | 2158.73 | 507.92 | 2786.91 | 327.75 | 3996.29 | 286.61 |

Overall, ash from corn stalks is richer in Si, Fe, and Mn (microelements). Cotton stalk ash is richer in Ca, Mg, K, and Zn (macroelements and TMEs). Those from Acacia auriculiformis wood are richer in Na, P, and Cu. They reported that the composition of the ash depends on the nature of the woody biomass, the growth conditions and the nature of the process that led to the production of the ash.

We observe that the mineral element and heavy metal contents of the ashes collected at the cyclone level and at the reactor level are similar for corn stalks and ears. This composition is different from that presented by Adamon19, who instead carried out gasification of corn cob pyrolysis cokes. This result can be explained by the fact that the corn cobs would have lost some of their constituents during pyrolysis before being gasified and confirms that the ash content depends on the nature of the biomass used.

The results obtained for Acacia auriculiformis wood ash corroborate those of Pan and Eberhardt3, who focused on the characterization of fly ash generated during the gasification of pine wood chips. They noted a high concentration in the order Ca-K-Mg-P for mineral matter and in the order Zn-Cu for TMEs. This suggests that wood in general is mainly rich in Ca and Zn.

It is also noted that with the exception of Ca, Na and Zn, the ashes collected in the reactor hopper contain higher levels of nutrients and Cu than those coming from the cyclone hopper. This could be justified by the presence of chemical components such as dolomite (CaMg(CO3)2) and limestone (CaCO3), which are frequently used in gasification.

This would be the reason why ash from the cyclone hopper in our case is highly alkaline. In addition, volatile ash constituents such as Zn evaporate at high combustion chamber temperatures 24-26. Consequently, volatile constituents can be extracted from the heated ash bed and concentrated in the cyclone ash through condensation. There is an enhanced concentration of these elements in the cyclone ash compared to the bottom ash. This is also confirmed by Yao and al.5 who explain that during gasification, certain alkali metals in combination with other chemical elements present in the gasifier, cause partial condensation thus leading to retention of residual ashes in the form viscous. These results corroborate those of Bachmaier and al.27 who showed that Cu, and the main nutrients Mg, P, Ca, and K are less volatile and are therefore, predominantly remaining in the residual ash. For Li et al.28, gasification conditions play an important role in ash deposition. Indeed, Lanzerstorfer25 observed that at combustor temperatures between 830 and 920 °C, Zn accumulates in the fly ash, while most nutrients (Ca, Mg) remain in the residual ash.

It is noted that the potassium contents in the bottom ash of all biomasses, except for corn cobs, are higher than those in the cyclone ash. Lanzerstorfer 25, attributes the results to the high reaction temperatures, which are sufficient to remove volatile heavy metals while remaining below the threshold for high potassium losses. Bachmaier et al.27, found that if high concentrations of highly volatile elements are present in bottom ash intended for use as a fertilizer, increasing the temperature of the combustion bed may reduce these elements in the bottom ash and lead to an increase in cyclone ash.

The bottom ash analyzed in this study could therefore be used in the field of agriculture in the form of organic fertilizer3, 9, 29.

However, the composition of mineral substances is not sufficient to conclude. Another key point is the concentration of trace elements in the ash obtained. Based on the data available in the literature, Table 4 shows the maximum authorized thresholds of TMEs in biomass ash for soil application.

Table 4: Maximum authorized limit for TMEs in biomass ash

Maximal concentration | Eco-SSL value from reference United States EPA 2003 3 | in Suisse from annex 2.6, ch. 2.2.1 of l’ORRChim (RS.814.81, 2011) 15 | In Royaume-Uni from ICRCL 30 |

Cu (mg/kg) | 70 | 100 | 130 |

Zn (mg/kg) | 160 | 400 | 300 |

Authorized limits vary from region to region. As the threshold values for Switzerland and the United Kingdom are close for both elements (Cu and Zn), we will use them for comparison with our results (Table 5).

Zn concentrations in the ash collected from the cyclone hopper are well above the threshold values of the two references (around 5 to 13 times). The ash is therefore less suitable for agricultural use. We will therefore focus the remainder of our analysis on the ash collected in the reactor hopper.

Comparison with the threshold values authorized in Switzerland shows that corn stalk ash and cotton stalk ash both comply with the 400 mg kg-1 limit for Zn. However, the Cu concentration of cotton stalk ash is high compared with the threshold (100 mg kg-1), whereas for corn stalk ash, it is relatively close to the threshold (123.122 mg kg-1).

With the values presented for the United Kingdom, the Cu concentration in corn stalk ash complies with the threshold limit, as does the Zn concentration in cotton stalk ash. However, the Cu concentration in cotton stalk ash is well above the threshold, while the Zn concentration in corn stalk ash is slightly above the threshold.

From the above, it can be deduced that corn stalk ash recovered from the reactor hopper is more suitable for agricultural use.

Table 5: Comparison of ETM concentrations with authorized limits

Elements | Acacia auriculiformis Wood | Corn cobs | Corn stalks | Cotton stalks | Limit in Suisse 15 | Limit in Royaume-Uni 30 | ||||

S2-cyclone bottom | S1-Gasifier Reactor bottom | S2-cyclone bottom | S1-Gasifier Reactor bottom | S2-cyclone bottom | S1-Gasifier Reactor bottom | S2-cyclone bottom | S1-Gasifier Reactor bottom | |||

Cu (mg kg-1) | 114.21 | 155.71 | 103.56 | 237.89 | 116.84 | 123.12 | 113.15 | 227.46 | 100 | 130 |

Zn (mg kg-1) | 3231.93 | 523.99 | 2158.73 | 507.92 | 2786.91 | 327.75 | 3996.29 | 286.61 | 400 | 300 |

Conclusion

This study analyzed the composition of gasification ash from four types of biomasses: corn stalks and cobs, cotton stalks, and wood residues, based on their mineral matter content, but especially their TME content, it emerged that only ash from maize stalks collected at the reactor hopper could be used in agriculture to fertilize soil. However, N should be added to boost the fertilizing effect. Similarly, appropriate dosing is required to dilute the ETM content and comply with the admissible limits.

Acknowledgements

The authors sincerely thank the heads of Songhaï Center of Benin for their acceptation to data collection in their gasification plant.

Funding Sources

There is no funding sources.

Conflict of interest

The author(s) declares no conflict of interest.

Data Availability Statement

The manuscript incorporates all datasets produced or examined throughout this research study

Ethics Approval Statement

No experiments on humans or animals

Authors’ Contribution

David Gildas Farid ADAMON and Charbel KINZO designed the study, performed the statistical analysis, and wrote the first draft of the manuscript. Djonoumawou Mèmèvêgni Grâce Floriane CHIDIKOFAN and Gloire AVIANSOU managed the literature searches and analyses of the study. All authors read and approved the final manuscript.

References

- Yao X, Zhou H, Zhao Z, Xu K. Research on dependence of concentration and transformation of inorganics in biomass gasification ashes upon particle size classification. Powder Technol. 2020;371:1-12.

CrossRef - Jie H, Chen P, Depletion of natural resources and environmental quality: Prospects of energy use, energy imports, and economic growth hindrances. Resources Policy. 2023; 86, Part A,104049. https://doi.org/10.1016/j.resourpol.2023.104049.

CrossRef - Mohammed A, Dongmei L, Mahtab Nazari, Ateeq S, Xiaomin Z, Donald L, Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renewable and Sustainable Energy Reviews. 2021; 139, 110691. https://doi.org/10.1016/j.rser.2020.110691.

CrossRef - Alavi-Borazjani SA, Capela I, Tarelho LAC. Valorization of biomass ash in biogas technology: Opportunities and challenges. Energy Reports. 2020;6:472-476. doi:10.1016/j.egyr.2019.09.010.

CrossRef - Yao X, Zhao Z, Chen S, Zhou H, Xu K. Migration and transformation behaviours of ash residues from a typical fixed-bed gasification station for biomass syngas production in China. 2020;201:117646.

CrossRef - Yao X, Zhao Z, Li J, Zhang B, Zhou H, Xu K. Experimental investigation of physicochemical and slagging characteristics of inorganic constituents in ash residues from gasification of different herbaceous biomass. Energy. 2020;198:117367.

CrossRef - Setiawan R, Hidayat HF, Dafiqurrohman H, Surjosatyo A, Dhelika R. Performance Evaluation of a Continuous Downdraft Gasification Reactor Driven by Electric Motors with Manual Mode of Operation. J Eng Technol Sci. 2022;54(4):220405. doi:10.5614/j.eng.technol.sci.2022.54.4.5.

CrossRef - Shahin M, Hossein D, MohammadSina H, Omid P. A comprehensive experimental and modeling investigation of walnut shell gasification process in a pilot-scale downdraft gasifier integrated with an internal combustion engine. Energy Conversion and Management. 2021; 231 (1), 113836. doi: https://doi.org/10.1016/j.enconman.2021.113836.

CrossRef - Bamboriya O, Varma A, Yadav J, Thakur L. Physicochemical and Pyrolysis Kinetic Aspects of Biomass Feedstocks. Environmental Science and Engineering. Springer, Cham. 2021; CHEMBIOEN: International Conference on Chemical, Bio and Environmental Engineering: 181-198. https://doi.org/10.1007/978-3-030-96554-9_13.

CrossRef - Silva FC, Cruz NC, Tarelho LAC, Rodrigues SM. Use of biomass ash-based materials as soil fertilisers: Critical review of the existing regulatory framework. Journal of Cleaner Production. 2019;214:112-124. doi:10.1016/j.jclepro.2018.12.268.

CrossRef - Joanna Irena O, Elzbieta W, Urszula W, Mariola W, Agata J. Utilization of Ashes from Biomass Combustion. Energies. 2023; 15, 9653. doi: https://doi.org/10.3390/en15249653

CrossRef - Oladele J.O, Abiodun K, Abiola U. A, Olawale S, Kehinde T. A. Potential use of biomass ash as a sustainable alternative for fly ash in concrete production: A review. Hybrid Advances. 2023; 4, 100076. doi: https://doi.org/10.1016/j.hybadv.2023.100076.

CrossRef - Guittat S. Recycler la cendre de bois de 7 manières utiles et écologiques. Mieux vivre autrement. Published 2019. https://www.mieux-vivre-autrement.com/recycler-cendre-de-bois-7-manieres-utiles-ecologiques.html.

- Albuquerque A, Angélica S, Merino A, Simone P. Chemical and mineralogical characterization and potential use of ash from Amazonian biomasses as an agricultural fertilizer and for soil amendment. Journal of Cleaner Production. 2021; 295, 126472. doi: https://doi.org/10.1016/j.jclepro.2021.126472.

CrossRef - Ji Young A, and Byung Bae P. Effects of wood ash and N fertilization on soil chemical properties and growth of Zelkova serrata across soil types. Sci Rep. 2021; 11, 14489. doi: https://doi.org/10.1038/s41598-021-93805-5

CrossRef - Mirha P, Mirsada S, Jasmina S, Alisa S, Sabina B, Selma ŠH, Farooq S. Heavy metals content in ashes of wood pellets and the health risk assessment related to their presence in the environment. Sci Rep. 2021; 11, 17952. doi: https://doi.org/10.1038/s41598-021-97305-4

CrossRef - Smo?ka-Danielowska D, Jab?o?ska M. Chemical and mineral composition of ashes from wood biomass combustion in domestic wood-fired furnaces. Int. J. Environ. Sci. Technol. 2022; 19: 5359–5372. doi: https://doi.org/10.1007/s13762-021-03506-9.

CrossRef - Marinélia N, Tobaldi M, Seabra P, Tarelho A.C, Labrincha A. Characterization of ashes produced from different biomass fuels used in combustion systems in a pulp and paper industry towards its recycling. Biomass and Bioenergy. 2022; 166, 106598. doi: https://doi.org/10.1016/j.biombioe.2022.106598.

CrossRef - Adamon F. Modélisation de La Cinétique de Gazéification Étagée de La Biomasse Tropicale?: Cas Des Balles de Riz et Des Rafles de Maïs. Université de Technologie de Compiègne; 2017.

- Patel SK, Satpathy HP, Nayak AN, Mohanty CR. Utilization of Fly Ash Cenosphere for Production of Sustainable Lightweight Concrete. J Inst Eng India Ser A. 2020;101(1):179-194. doi:10.1007/s40030-019-00415-6

CrossRef - Suraj P, Kanika S, Sangram D, Marisennayya S, Deshmukh P, Sunil K, Anitha T, Balamurugan V, Pandiselvam R, Manoj K. Unlocking the potential of cotton stalk as a renewable source of cellulose: A review on advancements and emerging applications. International Journal of Biological Macromolecules2024; 261, Part 2, 129456. doi: https://doi.org/10.1016/j.ijbiomac.2024.129456.

CrossRef - Miranda T, García-Mateos R, Arranz J, Sepúlveda F, Romero P, Botet-Jiménez A. Selective Use of Corn Crop Residues: Energy Viability. Appl. Sci. 2021; 11(7): 3284. doi: https://doi.org/10.3390/app11073284 - 6 Apr 2021.

CrossRef - Mathieu C, Pieltain . Analyse Chimique Des Sols Méthodes Choisies. Tec et Doc/Lavoisier,.; 2003.

- Kovacs H, Dobo Z, Koos T, Gyimesi A, Nagy G. Influence of the Flue Gas Temperature on the Behavior of Metals during Biomass Combustion. Energy Fuels. 2018;32(7):7851-7856. doi:10.1021/acs.energyfuels.8b00796

CrossRef - Lanzerstorfer C. Grate-Fired Biomass Combustion Plants Using Forest Residues as Fuel: Enrichment Factors for Components in the Fly Ash. Waste Biomass Valor. 2017;8(1):235-240. doi:10.1007/s12649-016-9565-6

CrossRef - Nurmesniemi H, Manskinen K, Pöykiö R, Dahl O. Forest fertilizer properties of the bottom ash and fly ash from a large-sized (115 MW) industrial power plant incinerating wood-based biomass residues. J Univ Chem Technol Metall. 2012;47:43-52.

- Bachmaier H, Kuptz D, Hartmann H. Wood Ashes from Grate-Fired Heat and Power Plants: Evaluation of Nutrient and Heavy Metal Contents. Sustainability. 2021;13(10):5482. doi:10.3390/su13105482

CrossRef - Li G, Wang C, Wang P, et al. Ash Deposition and Alkali Metal Migration during Zhundong High-alkali Coal Gasification. Energy Procedia. 2017;105:1350-1355. doi:10.1016/j.egypro.2017.03.497

CrossRef - Yao X, Mao J, Li L, et al. Characterization comparison of bottom ash and fly ash during gasification of agricultural residues at an industrial-scale gasification plant – Experiments and analysis. Fuel. 2021;285:119122. doi:10.1016/j.fuel.2020.119122

CrossRef - Anon. Soil guideline values for lead contamination. Published online 2002.