Design and Fabrication of an Automatic Waste Segregation and Monitoring System

1

Mechanical Engineering Department,

Faculty of Engineering and Technology, Gurukula Kangri (Deemed to be University),

Haridwar,

Uttarakhand

India

2

Mechanical Engineering Department,

Quantum University,

Roorkee,

Uttarakhand

India

3

Computer Science and Engineering Department,

Faculty of Engineering and Technology, Gurukula Kangri (Deemed to be University),

Haridwar,

Uttarakhand

India

4

Electronics and Communication Engineering Department,

Faculty of Engineering and Technology, Gurukula Kangri (Deemed to be University),

Haridwar,

Uttarakhand

India

Corresponding author Email: kapildevsharmagkv@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.19.3.15

Copy the following to cite this article:

Sharma K. D, Prajapati R. K, Srivastava S, Fore V, Amrish A. Design and Fabrication of an Automatic Waste Segregation and Monitoring System. Curr World Environ 2024;19(3). DOI:http://dx.doi.org/10.12944/CWE.19.3.15

Copy the following to cite this URL:

Sharma K. D, Prajapati R. K, Srivastava S, Fore V, Amrish A. Design and Fabrication of an Automatic Waste Segregation and Monitoring System. Curr World Environ 2024;19(3).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2024-07-08 |

|---|---|

| Accepted: | 2024-12-09 |

| Reviewed by: |

Karan Belsare

Karan Belsare

|

| Second Review by: |

Sonu Kaur

Sonu Kaur

|

| Final Approval by: | Dr. Gopal Krishan |

Introduction

Around 62 metric tons of solid waste is generated every year in India but it is not being managed effectively in most of the cities which is leading to serious health problems and environmental destruction in many cities1. In many Indian cities, open dumping of waste in landfill sites is unplanned and unregulated but has become a common method of waste disposal2. Currently, India is dealing with many challenges out of which improper waste management is a major challenge. The most difficult challenges in waste management are waste segregation and waste-to-energy conversion. Improper waste collection, treatment, transportation, and disposal of waste generated causes significant damage to the environment3. Waste generation due to industrialization, urbanization, and increasing urban population is continuously increasing 4,5 . Many researchers have found that segregation, collection, transportation, treatment, and disposal in the scientific manner of solid waste is grossly inadequate in many Indian cities, leading to environmental problems and reduced quality of life 6–10. If we talk about India, right now only five states are working on the source separation of waste, all other states are still dumping mixed waste together at the dump sites 9,11. Segregation of waste, door-to-door waste collection, recycle and reuse options, waste treatment techniques, availability of land, and discarding capacity are some of the major issues of waste management 12–14.

The fruitful value of solid waste cannot be obtained until the recycled waste is completely recycled, and the energy extracted from the non-recyclable waste must be extracted 15,16. Most cities in India still use the traditional method of waste segregation in which waste is segregated by ragpickers. This method is time-consuming and ineffective and also adversely affects the health of people coming in contact with such waste 17–19. Despite awareness campaigns, people are not segregation waste at their houses. In such a situation, households and municipalities need an affordable and easy-to-use solution to segregate waste automatically.

Modern solid waste management regulations are heavily focused on the segregation of waste composition at source and their treatment with their specific treatment methods. Government of India launched a program of “Swachh Bharat Mission” to make a clean India 20,21. Now, the waste management authority is focused on waste collection and separation of waste in a useful manner. There are various technologies available around the world to manage solid waste but systematic segregation of waste is an important part of any successful waste management technology. Source segregation of solid waste is useful to decrease the amount of waste for landfills but also increase the rate of recycling 22–24. There are many benefits of AWSMS, including: protecting the environment by reducing pollution, reducing the amount of waste going to landfills, reducing the need for manual labour, a cost-effective, efficient, time-saving, and easy-to-control system5,11. Therefore, the objective of this paper is to design and fabricate an automated waste segregation and monitoring system (AWSMS) that automatically segregates waste into dry, wet, and metal without human intervention. This paper is divided into two parts. Section 1, provides a component wise working and methodology of automatic solid waste segregation system. Section 2 is well-focused on the design, fabrication, and performance testing of the system. This paper can assist the municipal decision-makers, administration, and researchers of countries those are still looking for effective, low-cost, environmentally compatible waste segregation systems.

Methodology

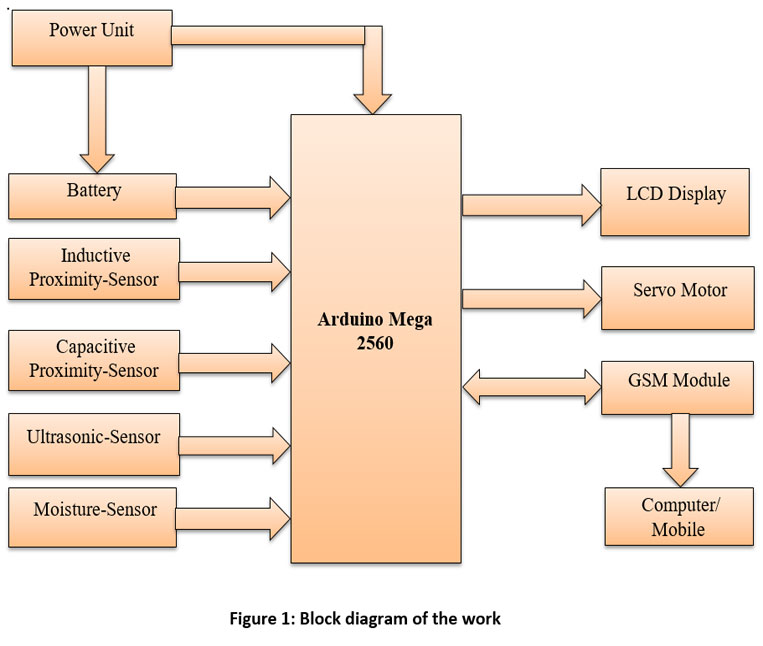

Microcontroller Arduino UNO has been used to operate the automatic waste segregation system. Each component linked to the Arduino UNO is configured using the Arduino IDE as shown in Figure 1. Embedded C++ language is used to write the program in the Arduino UNO which reads out the input/output signals of all the connected components.

All the sensors sense the garbage when it enters the system and send a signal to the Arduino Mega 2560. These signals help the servo motor to rotate in both directions i.e. clockwise and anti-clockwise directions so that the waste can be dumped into respective dustbin. All the data received from the Arduino UNO using the sensors is sent to the cloud through the use of the Node MCU. Thus, messages displayed in the LCD to users, and the received status will be communicated to those authorized to send the BIN status via the MQTT protocol. LCD display the type of waste detected by the sensor and also display the level of the bins level to the operator.

| Figure 1: Block diagram of the work

|

Working Principal

In this system, six sensors have been used of which three are used to determine the type of waste while the remaining three are used to find out the status of the bin either the bin is full or not. In order to determine the type of waste capacitive proximity sensor, moisture sensor, and inductive proximity sensor, while, three ultrasonic sensors have been used to detect whether three different bins are full or not. A capacitive proximity sensor has been used to sense dry waste i.e. paper, cardboard, plastic, wood, etc., a moisture sensor detects wet waste i.e. food waste, vegetable & fruit waste, etc., while an inductive proximity sensor detects metallic waste i.e. copper, aluminum, iron, etc.

When any object i.e. garbage is inserted into the waste hopper unit of the system, the sensors detect it. After detecting the object, if it is dry then the rotating plate brings the dry bin below the waste hopper, similarly if the object is wet or metallic then the dry and metallic bin allows the object to fall inside. The rotation of the plate and the falling of the waste into the bin is done by the use of relay and servo-motor. As soon as the waste is detected and sensed, the LCD of the system also displays whether the waste is dry, wet, or metallic. LCD also tells the count of garbage. The layout of the waste segregation system is displayed in figure 2.

| Figure 2: Layout of Waste Segregator

|

The GSM module gives communication between the rotating bin and workers. When the bin is full then with the help of the GSM module a message is sent to the cleaning authority that "bin is full".

Hardware and Software Requirements

Technical Specifications

Voltage required- 5V

Voltage at the input- 7-20V

DC per I/O pin- 20 mA

Memory of flash- 32 KB

Frequency of clock- 16 MHz.

Digital pins required: 14

Analog pins required: 6

Components requirements

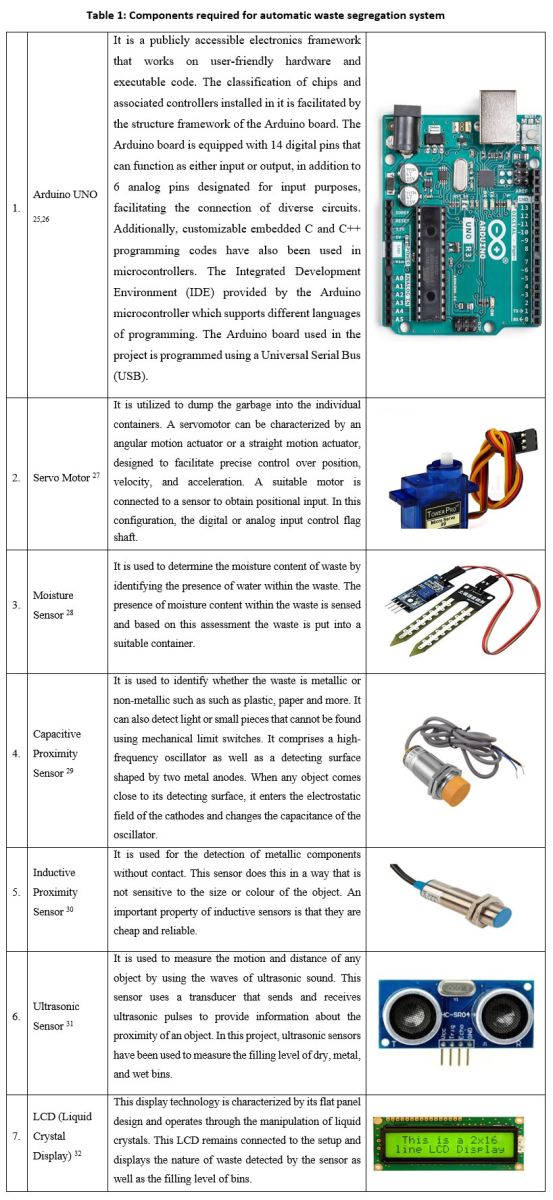

A List of various components and their working is listed in table 1.

| Table 1: Components required for automatic waste segregation system

|

Design and Fabrication

Design

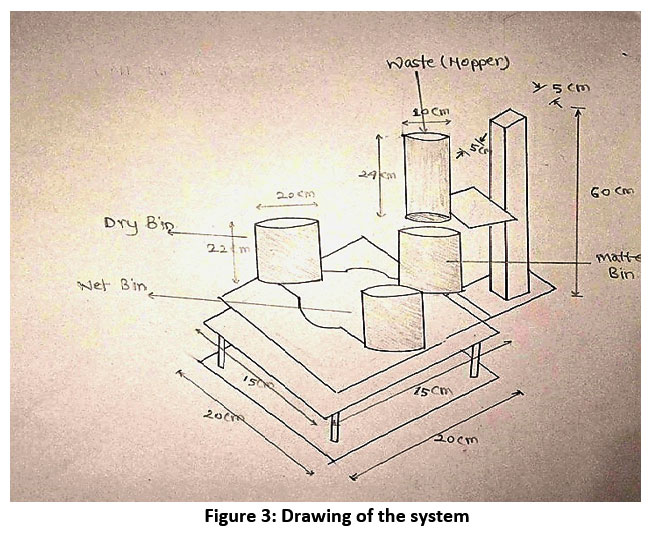

Components of Automatic Waste Segregation and Monitoring System has been designed on an AutoCAD software. A rough sketch of the system is drawn including all the dimensions as shown in the fig.3.

| Figure 3: Drawing of the system

|

The supporting frame designed on AutoCAD is shown in fig.4. which contain base and vertical design of the supporting pillar of the frame.

| Figure 4: Supporting Frame

|

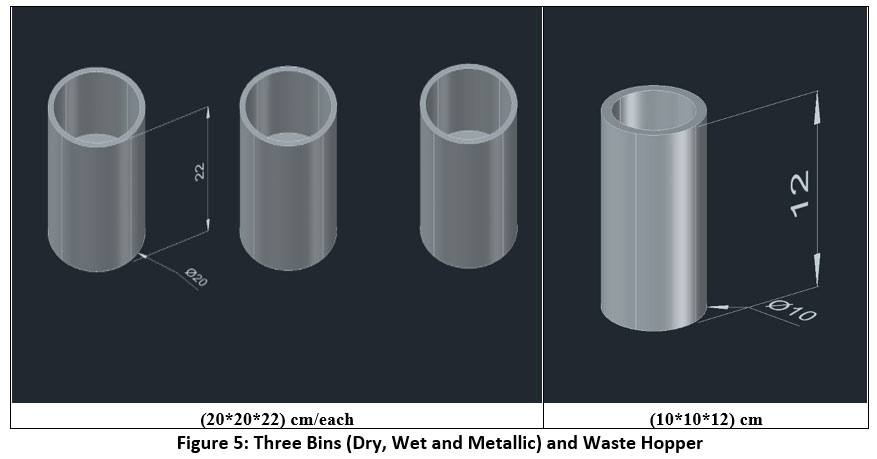

Three bins, each of capacity 5 kg, and one hopper have been designed with the help of AutoCAD as shown in the fig.5. Each bin has been rigidly fixed on the rotating plate.

| Figure 5: Three Bins (Dry, Wet and Metallic) and Waste Hopper

|

Fabrication

Almost all components are nut-bolted or riveted together but the vertical iron column and the base of the system are joined through arc welding. A complete assembly of the system has been fabricated, and various samples have been tested to separate wet, dry, and metal waste into separate bins.

Results

All components of automated waste segregation system are designed on AutoCAD software. After assembling all the components, the performance test of the system was conducted on household waste which included dry waste like paper, dry cloth, wood chips, plastic waste, cardboard pieces, etc., wet waste like vegetable peels, fruit pieces, lemons, Bananas, etc., and metal waste like safety pins, small metal pieces, aluminium sheet pieces, tin sheet pieces, etc. During testing of the system, it was found that the system takes approximately 2.5 seconds to separate metal waste, approximately 3.5 seconds to separate wet waste, and approximately 5.6 seconds to separate dry waste. This system segregates only one type of waste at a time. If a waste was previously wet but now it has become dry, then the system will consider it as dry waste. The accuracy of the system was noted to be around 98% for 100 samples of waste. Table 2 shows the test results of the waste after being subjected to the waste segregator.

Table 2: Testing results of the waste

Type of waste | Waste Name | Identified or Not |

Dry waste | Paper | Yes |

Wood Chips | Yes | |

Plastic | Yes | |

Cardboard pieces | Yes | |

Wet Waste | Vegetable peels | Yes |

Fruit pieces | Yes | |

Lemons | Yes | |

Banana | Yes | |

Metal Waste | Safety pins | Directly goes down into metal waste bin |

Small metal pieces | ||

Aluminium sheet pieces | ||

Tin sheet pieces |

Discussion

During testing, it was also found that the amount of waste should be proportional to the size of the system. This technology proves useful in ensuring that waste segregation is realistic and good for the environment. Mixed waste can be separated by being put through a rotating system (trommel system) before being put into the automated waste separation system. The trommel system is a rotating drum enclosed with a sieve. Due to the rotational motion of the trommel, the waste separates into individual particles, causing the smaller particles to pass through the sieve (<300 mm), while the bulk (>300 mm) stays inside the drum. The agitation action of waste removes the necessity for actions of manual stirring. The moisture content can be removed by airflow through the trommel’s drum.

Conclusion

India is a developing country and its population is the largest among all the countries of the world, generates a huge amount of waste every day. Urban India has generated abound 62 million tons of MSW annually of which, 70% is collected and only 20% is treated. Different types of waste have different natures so dumping all the waste together is not good at all as it makes it very tough to reuse the waste. Segregation of waste plays a key role in reusing the waste. The process of waste management is significantly simplified when segregation occurs at the source.

Hence, the model presented in this paper is an automated waste segregation model which is efficient, sustainable, low power driven as well as requires very little human supervision. This system can detect the status of when the bin is full and calls the workers to collect the waste from the bin. It effectively reduces the manpower, collection time, and fuel consumed by the collection vans. This system is in perfect sync with the idea of ??a smart city and can replace the old garbage bin collection system. In the future, it is anticipated that collection bins will utilize solar energy, complemented by advanced segregation technologies such as digital image processing. This innovation will enhance the quality of the waste collected, thereby optimizing storage capacity. This system can be effectively used in local societies, colleges, offices, industries, etc. It can also be recommended on a larger scale with slight modifications like using robotic arms and conveyor belts to ease the separation process. Additionally, more sensors can be used to separate biodegradable and non-biodegradable waste, plastic, recyclable, medical, e-waste, etc.

Acknowledgement

We are grateful to the Haridwar Nagar Palika Parishad (HNPP) for providing us with valuable solid waste information. We express our gratitude to colleagues, friends, and organizations from all over the world who have provided valuable information.

Funding Sources

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The author(s) do not have any conflict of interest.

Data Availability Statement

The manuscript incorporates all datasets produced or examined throughout this research study.

Ethics Statement

This research did not involve human participants, animal subjects, or any material that requires ethical approval.

Informed Consent Statement

This study did not involve human participants, and therefore, informed consent was not required.

Author Contributions

Kapil Dev Sharma contributed in Conceptualization, Data curation, and Formal Analysis. Rishi Kumar Prajapati worked on Resources and Methodology. Vivudh Fore contributed in Validation and writing original draft. Amrish contributed in writing–review & editing. Shobhit Srivastava worked as a Project administration and Supervision.

References

- Sharma KD, Jain S. Overview of Municipal Solid Waste Generation, Composition, and Management in India. J Environ Eng. 2019;145(3):1-18. doi:10.1061/(asce)ee.1943-7870.00014902.

CrossRef

- Sharma S, Upadhyay, S, Singh B. Employment Opportunities With Promoting Waste Management in India. J CleanWAS. 2019;3(1):10-15. doi:10.26480/jcleanwas.01.2019.10.153

CrossRef - Singhal A, Gupta AK, Dubey B, Ghangrekar MM. Seasonal characterization of municipal solid waste for selecting feasible waste treatment technology for Guwahati city, India. J Air Waste Manag Assoc. 2022;72(2):147-160. doi:10.1080/10962247.2021.1980450

CrossRef - Hagos K, Zong J, Li D, Liu C, Lu X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew Sustain Energy Rev. 2017;76(September):1485-1496. doi:10.1016/j.rser.2016.11.184

CrossRef - Ajay VP, Kumar BM, Kishanth A, et al. Automatic waste segregation and management. 2020 Int Conf Comput Commun Informatics, ICCCI 2020. 2024;13(6):1829-1834. doi:10.1109/ICCCI48352.2020.9104196

CrossRef - Siddappaji, Sujatha K, Radha RC. Technologies for segregation and management of solid waste: A review. 1st Int Conf Emerg Trends Eng Technol Sci ICETETS 2016 - Proc. Published online 2016. doi:10.1109/ICETETS.2016.7603046

CrossRef - Mittal A, Mittal S. Cloud-based segregation of waste in smart cities. Int J Sci Technol Res. 2019;8(9):208-212.

- Badoi IR, Lie I. Automatic Waste Segregation System. 2022 15th Int Symp Electron Telecommun ISETC 2022 - Conf Proc. Published online 2022. doi:10.1109/ISETC56213. 2022.10010184

CrossRef - Chand Malav L, Yadav KK, Gupta N, et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J Clean Prod. 2020;277:123227. doi:10.1016/j.jclepro.2020.123227

CrossRef - Nagori M, Jachak RS, Chaudhari PP. A framework for segregating solid waste by employing the technique of image annotation. 2019 2nd Int Conf Adv Comput Commun Paradig ICACCP 2019. Published online 2019:1-6. doi:10.1109/ICACCP.2019.8882932

CrossRef - Islam S, Talukder SA, Reza MS, Joy AA. Design and Implementation of an Automatic Waste Segregation System. IRJMETS. 2023;5(04):3744-3756.

- Paul S, Choudhury M, Deb U, Pegu R, Das S, Bhattacharya SS. Assessing the ecological impacts of ageing on hazard potential of solid waste landfills: A green approach through vermitechnology. J Clean Prod. 2019;236:117643. doi:10.1016/j.jclepro.2019.117643

CrossRef - M. Gimonkar R. Automated Waste Segregator. J Res Eng Appl Sci. 2024;6(1):43-47. doi:10.46565/jreas.2021.v06i01.008

CrossRef - Kumar S, Yadav P, Kumar D, Patel A. Automatic Waste Segregation System. IJSRED. 2024;6(September):107-111.

- Saidan MN. Cross-sectional survey of non-hazardous waste composition and quantities in industrial sector and potential recycling in Jordan. Environ Nanotechnology, Monit Manag. 2019;12(March):100227. doi:10.1016/j.enmm.2019.100227

CrossRef - Alfaia RG de SM, Costa AM, Campos JC. Municipal solid waste in Brazil: A review. Waste Manag Res. 2017;35(12):1195-1209. doi:10.1177/0734242X17735375

CrossRef - Ibáñez-Forés V, Bovea MD, Coutinho-Nóbrega C, de Medeiros HR. Assessing the social performance of municipal solid waste management systems in developing countries: Proposal of indicators and a case study. Ecol Indic. 2019;98(February 2018):164-178. doi:10.1016/j.ecolind.2018.10.031

CrossRef - Rana R, Ganguly R, Gupta AK. An assessment of solid waste management system in Chandigarh City, India. Electron J Geotech Eng. 2015;20(6):1547-1572.

- Joshi R, Ahmed S. Status and challenges of municipal solid waste management in India?: A review. Cogent Environ Sci. 2016;2(1):1-18. http://dx.doi.org/10.1080/23311843.2016.1139434

CrossRef - Deshpande D, Kapur A. Swachh Bharat Mission-Gramin (SBM-G) under the Ministry of Drinking Water and Sanitation (MoDWS), Goverment of India. Centre for Policy Research, New Delhi. Published 2018. Accessed March 10, 2018. http://accountabilityindia.in/sites/default/files/pdf_files/BudgetBrief_SBM-G_2017-18.pdf

- CPHEEO-Part I. Swachh Bharat Mission- Municipal Solid Waste Management Manual Part I: An Overview. CPHEEO (Central Public Health and Environmental Engineering Organization) MINISTRY OF URBAN DEVELOPMENT, India. Published 2016. Accessed November 26, 2018. http://cpheeo.gov.in/upload/uploadfiles/files/Part1(1).pdf

CrossRef - Tan ST, Ho WS, Hashim H, Lee CT, Taib MR, Ho CS. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers Manag. 2015;102:111-120. doi:10.1016/j.enconman.2015.02.010

CrossRef - Pickin J, Randell P, Trinh J, et al. National Waste Report 2018 Prepared for Department of the Environment and Energy. Blue Environment Pty Ltd. Published 2018. Accessed June 14, 2019. https://www.environment.gov.au/system/files/resources/7381c1de-31d0-429b-912c-91a6dbc83af7/files/national-waste-report-2018.pdf

- Rajesh P. Solid waste management- sustainability towards a better future, role of CSR – a review. Soc Responsib J. Published online 2019. doi:10.1108/SRJ-11-2018-0286

CrossRef - Kumar SG. Automatic Waste Segregator System. Int J Res Publ Rev. 2021;2(7):1794-1802. www.ijrpr.com

- Abhinav Nishanth K, V PP, Gaikwad GA, Students U, Professor A. AUTOMATED WASTE SEGREGATION SYSTEM. J Emerg Technol Innov Res. 2021;8(8):47. www.jetir.org

- B-Doddabasavana G, Mubashira B, Afreen, Manjula S, Bhagya L. Automatic Waste Segregation. Int J Res Appl Sci Eng Technol. 2016;11(5):1-23.

- Pai RR, Bangera PJ, Shaikh MM, Prajwal P, Shetty RP. Design and development of an automatic dry waste segregator for household and institutional wastes. Mater Today Proc. 2022;52:1048-1054. doi:10.1016/j.matpr.2021.10.487

CrossRef - Ajay VP, Kumar BM, Kishanth A, et al. Automatic waste segregation and management. 2020 Int Conf Comput Commun Informatics, ICCCI 2020. 2020;9(06):715-718. doi:10.1109/ICCCI48352.2020.9104196

CrossRef - AM N, S N, K N, C M, G DM. Automatic Waste Management and Segregation System using IoT. Int J Eng Res Technol. 2021;9(12):132-136. www.ijert.org

- Gupta NS, Deepthi V, Kunnath M, Rejeth PS, Badsha TS, Nikhil BC. Automatic Waste Segregation. Proc 2nd Int Conf Intell Comput Control Syst ICICCS 2018. 2018;(June):1688-1692. doi:10.1109/ICCONS.2018.8663148

CrossRef - Badoi IR, Lie I. Automatic Waste Segregation System. 2022 15th Int Symp Electron Telecommun ISETC 2022 - Conf Proc. 2022;(06):1488-1490. doi:10.1109/ISETC56213. 2022.10010184

CrossRef