Effect of Potato Starch on thermal & mechanical properties of Low Density Polyethylene

Shahrzad Khoramnejadian1 * , Jamileh Jamali Zavareh2 and Shirin Khoramnejadian3

1

Department of Environment,

Islamic Azad University,

Damavand,

Iran

2

Department of Environment,

Alborz province,

Karaj,

Iran

3

Islamic Azad University,

Tehran,

Iran

DOI: http://dx.doi.org/10.12944/CWE.8.2.06

Copy the following to cite this article:

Khoramnejadian S, Zavareh J. J, Khoramnejadianc S. Effect of Potato Starch on thermal & mechanical properties of Low Density Polyethylene. Curr World Environ 2013;8(2) DOI:http://dx.doi.org/10.12944/CWE.8.2.06

Copy the following to cite this URL:

Khoramnejadian S, Zavareh J. J, Khoramnejadianc S. Effect of Potato Starch on thermal & mechanical properties of Low Density Polyethylene. Curr World Environ 2013;8(2). Available from: http://www.cwejournal.org/?p=4361

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2012-10-05 |

|---|---|

| Accepted: | 2013-06-05 |

Plastics are one of the major parts of municipal waste.1 Most of the studies developed by blending petroleum based polymers with natural biodegradable materials that not only conserved the environment, petroleum reserves and landfills but also decrease the CO2 production and generally culminate to the sustainable development. The biodegradable polymers are the materials that converted in to the natural compounds of water, CO2, methane and other biological component by microorganisms such as fungi, bacteria, algae and other natural agents.2

Low density polyethylene is employed in packaging industries and production of bags, composites and agricultural mulches [3]. Study on the starch based synthetic polymers has begun from 1970s.4 There is a special attention to use starch as biodegradable filler.5 Starch is an abundant, biodegradable, recycling and inexpensive natural polymer obtainable from many botanical sources like potato, Cassava, corn.6,7,8 Biodegradable starch based polymer has a potential to produce in a large scale and low cost.9 Usage of starch based polymers has a benefit for environment conservation, because they reduce an exploitation of the nonrenewable resource. Consume a nonrenewable resource emit CO2 that caused a global warming.

Starch composed of amylose and amylopectin. The amount of amylose and amylopectin are different between varies source of starch. Rate on this two had an effect on product behavior. Potato is one of the sources of starch in the world.

A biodegradable plastic is the one which can be processed by the bacteria to the simpler forms. Biodegradable plastics has similar properties like as the common plastics but it can be degraded by microorganism after disposal in the soil or other environments.10 Biodegradation occurs when microorganism such as bacteria or fungi consumes polymer in an aerobic or anaerobic environment. Output of degradation process includes: Carbon dioxide, methane and other natural products.11

Several mechanisms are involved in the degradation of plastics, one of them is a microbial degradation in which microorganisms such as fungi or bacteria consume the materials. The degradation process is based on the plastics environment and their application. It’s better to estimate the biodegradability characteristics of the plastic materials under natural condition where the plastic wastes are exposed under the natural biological process in the nature.12

Weight loss is a common method to measure the rate of biodegradation of polymer samples. In this project biodegradable compound of Low Density Polyethylene (LDPE) with potato starch was made. Polyethylene grafted maleic anhydride (PE-g-Ma) used as a compatibilizer. Potato starch used as biodegradable filler in a different amount of 20, 30 and 40 percent. The amount of comaptibilizer was the same in all samples and about 10%. Biodegradability of compounds was determined by soil burial test and exposure to the mould growth. The effect of biodegradable filler on mechanical and thermal properties of blend were studied.

Experimental

Low Density Polyethylene (LDPE) with commercial grade 0200 prepared from Bandar Imam petrochemical complex, IRAN. Food grade potato starch obtained from Alvand co. IRAN. Glycerol with food grade belongs to Merck co. Germany. Polyethylene grafted maleic anhydride (PE-g-Ma) produces in Karankin Co., IRAN. Olive oil used as a moisturizer.

Starches powder plasticized with 25 wt% glycerol at 180°c for 10 minute. Samples were processed in HBI system (Haake Buchler Company from UK) with 60 rpm in 160°C. Sample sheets (0.4 mm thickness) were prepared by using Hot Mini Press. The tensile properties were measured by Santam (STM-20) instrument.

The suspension prepared in distilled water with 0.05% dioctyl sodium sulphosuccinate. Spore solution was put in sterile Petri dish. The polymer samples immerse into suspension. Then transferred to another sterile Petri dish and incubated in humidity greater than 90% and 30° C for 84 days. According to standards 8 kind of mould species included Aspergillus niger, Aspegillus terreus, Aureobasidium pullulans, Poecilomyces variotii, Penicillium funiculosum, Penicillium ochrochloron, Scopulariopsis brevicaulis, Trichoderma viride used for test.

A METTLER-TOLEDO differential scanning calorimeter (DSC) was used for Thermal analysis. Samples of 10 to 15 mg were initially heated in a nitrogen atmosphere from 25°C to 170°C at a heating rate of 10 oC/min. The samples were then cooled from 170°C to 25°C at a cooling rate of 10oC/min. The melting point reported here is the temperature of the maximum in the melting peak.

Samples cut in strip shape and buried into soil for 8 months. Samples were weighted before soil burial. At the end of the second, fourth and eight month samples were removed of soil and weighted.

Result and discussion

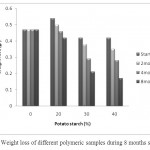

The weight loss of polymer sheets during biodegradation in soil indicates the amount of degradation in natural environment. Soil microorganism is attacking the samples. Potato starch content consumed by soil microorganisms, then make a fracture in polymer chain. In general, the potential of soil biodegradation is calculated by the following equation:

Soil biodegradation (%) = [(W-W0) / W0] × 10 ...(1)

Here W is a secondary weight of sample and W0 is a primary weight of sample.

|

Figure 1: Weight loss of different polymeric samples during 8 months soil burial. Click here to View figure |

According to the Fig 1, after eight months soil burial pure LDPE didn’t show any change in weight. Weight loss of samples with different amount of potato starch has been observed from second months. Highest degree of biodegradation belonged to the sample with 40% potato starch content. Weight loss indicated the starch removal from the polymer matrix by soil microorganisms. Soil environment contain a different kind of microorganism and macro organisms. Soil microorganisms attacked the polymer strips. Microorganisms attracted to the potato starch content of compounds. Microorganisms consumed potato starch in the polymer matrix and caused a fractured in the LDPE chain. Because of the existence of maleic anhydride – that made a chemical bond between LDPE and potato starch- degradation of potato starch caused a fracture in the polymer matrix and biodegradation of LDPE.7

|

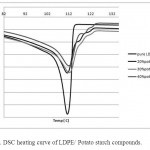

Figure 2: DSC heating curve of LDPE/ Potato starch compounds. Click here to View figure |

Fig 2, show the DSC heating curve of LDPE/ Potato starch compounds.

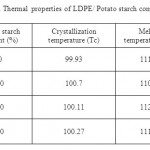

The ‘‘crystallization temperature (Tc)’’ an ‘’melting temperature (Tm )’’ expressed on table 1.

It can be seen there is a slight increase in Tc, and also incorporating the starch in the polymer causes small variation in Tm.

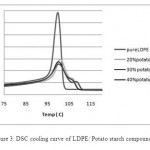

Rate of amylopectin and amylose of starch affects starch based product. Highest amount of amylase in the potato starch caused an increasing in the crystallinity of final potato starch based product. It might be brought about by the presence of the potato starch particles in polyethylene matrix that hinder the crystallization of LDPE molecules, therefore disordering increases a bit and crystallinty content decreases. Fig 3. Show the cooling curve of LDPE/ Potato starch compounds

This can be a result of nucleating effect of potato starch that causes the crystallization of PE molecules starts sooner and the peak temperature take places in higher temperature. Crystallization peak area for LDPE/potato starch compounds were smaller than that of LDPE, because of hindering effect of potato starch particles. This result also reported by other researchers.8

|

Figure 3: DSC cooling curve of LDPE/ Potato starch compounds. Click here to View figure |

|

Table 1: Thermal properties of LDPE/ Potato starch compounds. Click here to View table |

Fungi colonized potato starch/LDPE surface over 80% of samples with 30% and 40 % of potato starch at the end of incubation. After 84-days incubations LDPE strips didn’t exhibit color change or mould growth. Result similar to other researchers work on polymer degradation.10

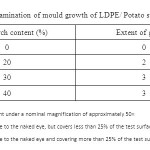

Table 2 show the results of visual examination mould growth of LDPE/ Potato starch

|

Table 2: Visual examination of mould growth of LDPE/ Potato starch compounds. Click here to View table |

Potato starch in polymer compounds had a digestible link for mould and fungi. Microorganisms recognized the potato starch carbon link as a nutrient source. Consumption polar hydrophilic starch caused the fractured into the polymer chain. Maleic anhydride created a link between two incompatible particles, so with starch removal a gap appeared in the polymer chain.

Through the gap microorganism’s access to the carbon link of low density polyethylene, the result is the polymer biodegradation.

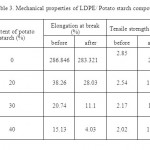

Table 3. Contain a result of mechanical properties of LDPE/ potato starch compounds.

Because of holes formed during biological degradation in soil mechanical properties of compound decreased.4 Highest destruction referred to samples with 40% of potato starch content. Expected with the increase the test time the better result is observed. That situation in accordance with Results is similar to other research.13 Soil microorganisms attacked the polymer. First of all, microorganisms attracted to the potato starch content of blends. Microorganisms consumed potato starch in the polymer matrix and caused a fractured in the LDPE chain. Because of the existence of maleic anhydride – that made a chemical bond between LDPE and potato starch- degradation of potato starch caused a fracture in the polymer matrix and biodegradation of LDPE.

|

Table 3: Mechanical properties of LDPE/ Potato starch compound. Click here to View table |

Conclusion

In this article biodegradable compound of Low Density Polyethylene (LDPE) with potato starch was made. Biodegradability of LDPE/potato starch compound estimated under soil burial and exposure to mould growth. Weight loses during 8 month soil burial shows the degradability of compounds in the natural environment. Thermal properties of LDPE/potato starch compound determined the effect of potato starch on melting point and other properties of final product. Microbial degradation in laboratory by 8 kinds of fungi approved the biodegradability of potato starch / LDPE compound. Existence of anhydride maleic created linkage between LDPE and potato starch, so consumption of potato starch in any environment caused a destruction of polymer matrix. Mechanical properties of LDPE/potato starch compound before and after soil burial indicated that compound were biodegradable.

References

- Kozlowska, A.; Gromadzki, D.; El Fray, M.; ŠtÄ•pánek, P. FIBRES & TEXTILES in Eastern Europe, 16, 6 (71), 85-88(2008).

- Rutkowska, M.; Heimowska, A.; Krasowska; K.; Janik, H.; Pol. J. Environ. Stud. 11, 267-274 (2002).

- Raj, B. ; Sankar, U.; Adv Polymer Tech, 23, 32-45(2004).

- Ratanakamnuan,U.; Aht-Ong, D. ;J. Appl. Polymer Sci, 100, 2725–2736(2006).

- Matzinos, P.; Bikiaris, D.; Kokkou, S., Panayiotou, C., J. Appl. Polymer Sci, 79, 2548-2557(2001).

- Parra, D.F. ; Tadini, C.C.; Ponce, P.; Lugao, A.B.; carbohydr. Polym, 58, 475–481(2004).

- Borghei, M.; Karbassi, A.; khoramnejadian, S.; Oromiehie, A.; javid, A.; Afr. J. Biotechnol. 9(26), 4075-4080(2010).

- Ciesielski ,W.; Tomasik, P. Bull. Chem. Soc. Ethiop. 17(2), 155-165(2003).

- Parra, D.F.; Tadini, C.C.; Ponce, P.; Lugao, A.B.; carbohydr. Polym, 58, 475–481(2004).

- Abdul Rahman, W.; Rasit Ali, R.; Zakaria, N.; 1st Int Conf Natural Res Eng Tech,Malaysia, 24-25th July, 2006.

- Raghavan, D.; Polymer Plast Tech Eng, 34, 41-63(1995).

- Orhan, Y.; Hrenović, J.; Büyükgüngör, H.; Acta Chim. Slov. 51, 579-588(2004).

- Wang, S.; Yu, J. ; Yu, J. polym. int. 54, 279-285(2005).