Enhancement of Thermal Efficiency of Traditional Indian Cooking Furnace (Chulha)

Ravindra Mohan1 * and Shankar Kumar1

1

Department of Mechanical Engineering M.E.(Heat Power and Thermal Engg.),

Lakshmi Narayan College of Technology,

Bhopal,

462 021

India

DOI: http://dx.doi.org/10.12944/CWE.6.1.07

Energy is the prime mover of economic growth and it is a wheel of modern economy. Future economic growth crucially depends on the long-term availability of energy, and cost of sources, availability, accessibility, and environmental friendly. India is a developing country and it needs more energy to accelerate the rate of development. India has the sixth position in the total energy consumption in the world. The energy resource is constant but energy consumption increases day by day. So each country requires more energy efficient equipment for the development and to save energy consumption. There are three ways for efficient energy conversion (a) Discover new energy resource (b) To minimize the energy losses (c) waste heat recovery. Here every human needs the energy for cook food. In India 74% population of India lives in villages and uses the conventional resources e.g. wood, cow dung and agriculture waste and available of bio-mass. So, I select rural area where mostly use bio-mass fuel, like wood and agriculture waste. The chulha (wood stove) use as a cook furnace for bio-mass in rural area. The traditional chulha give low thermal efficiency. In view of conservation of wood fuel and reduction of smoke from the kitchens of rural. In view of conservation of wood fuel and reduction of smoke from the kitchens of rural India, the Ministry of Non-conventional Energy Sources(MNES), Government of India, launched a National Programme on Improved Chullhas(NPIC) during 1984- 85. The NPIC measure traditional Chullhas have thermal efficiency is 8 to 10 percent but in my modified model, thermal efficiency has improved by 15 to 17 percent through extra supply of air. The thermal efficiency of modified chulha over the conventional chulha is 7 % to 9% more. In my modified model do not create pollution into environment due to complete combustion of fuel.

Copy the following to cite this article:

Mohan R, Kumar S. Enhancement of Thermal Efficiency of Traditional Indian Cooking Furnace (Chulha). Curr World Environ 2011:6(1);61-66. DOI:http://dx.doi.org/10.12944/CWE.6.1.07

Copy the following to cite this URL:

Mohan R, Kumar S. Enhancement of Thermal Efficiency of Traditional Indian Cooking Furnace (Chulha). Curr World Environ 2011:6(1);61-66. Available from: http://www.cwejournal.org/?p=1274

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2011-03-10 |

|---|---|

| Accepted: | 2011-04-07 |

Introduction

The total population of India is 1210 million on Jan 2011 but as per the Indian census of 2001, there are 638,365 villages in India and about 74% population lives in these villages.8 Those 74% populations use the Chulha to cook the food. Because of the urban facilities are not still available in rural areas, such as drinking water supply, cooking gas supply and electricity supply etc. that are not available in most of the rural areas. The most important activity of Human bodies is to cook food for there routine work and they consume 20% to 30 % of time of one day to cook the food at Chulha. Thus they consume time as well as fuel also for a long time.3 An effort is made to increase the efficiency of chulha thus it save the time and daily utilized energy.

Cooking furnace (chulha)

- Conventional Chula: it is a C shaped wall with two open faces, one at the top and other is front. The front open faces to feed the fuel and other top face is to put the pot.

- Modified Chulha: it is nothing but an improvement of conventional chulhas where the holes are provided to supply the excess air, for the purpose of complete combustion of the fuel.6, 7

Literature Review

In view of conservation of wood fuel and reduction of smoke from the kitchens of rural India, the Ministry of Non-conventional Energy Sources(MNES), Government of India, launched a National Program on Improved Chullhas (NPIC) during 1984- 85. The improved Chullhas are wood stoves designed through research in order to conserve fire wood and protect rural ladies against the ill effects of fumes and gases that come out while wood and other biomass is burnt during cooking. The traditional Chullhas have an efficiency of only 8 to 10 percent whereas improved Chullhas have a minimum thermal efficiency of 20 to 25 per cent. Thus, an improved chullha produces more energy and consumes less wood without producing too much ash and smoke.1,4

|

Modified Indian Cooking Furnace Chulha Click here to View figure |

Some Novel Modified Chulha of NPIC

- Vivek Portable Cook stove

- Adhunik Cook stove

- Grihalaxmi cook stove

- Bhagyalaxmi cook stove

- Parvati cook stove

- Laxmi cook stove

Experimental Set Up of Modified Cooking Furnace

The experimental set is made as shown in fig to make the observation. Here the experimental set up is divided in two parts (A) Chulha, (B) cooling space

|

Experimental set up of modified cooking furnace Click here to View figure |

|

Experimental set up of modified cooking furnace Click here to View figure |

Part (A) of Chulha

That chulha over ground make like traditional indoor cooking chulha in India, but in modified chulha have a small change. That is hollow walls of chulha the “C” shape. That hollow shape is possible by soil or clay plate assembles. There is two C shape outer is big and inner is small. After that assemble together and gate a complete hollow C shape. The top portion also covered by flat C shape. In the inner C have hole. Total 12 hole in inner C, shape of chulha. Hole’s diameter is one inch each.

Part (B) Cooling Space

The second part cooling space, use for increase the flow rate of feed air in to combustion chamber, that is the main object of cold space in modified Indian cooking furnace (chulha). The cold space developed under ground in earth. The underground of cold space is one feet depth earth surface install position of chulha. Here two step rectangular pit are used of size (length X bight X depth) 3×2×1 and 2×1×1 cubic feet. The second step pit (2×1×1 cubic feet) of cold space is cover with flat stone plate. The flat stone plat has minimum one inch thickness. That thickness is must be suitable to capable soil load. The first step pit (3X2X1cubic feet) has cover by soil; above cold space has minimum one feet thick layer of soil (mud). In Cold space has two gates, one is inlet gate and other is outlet gate. At inlet gate fit a PVC pipe, have diameter six inches. The PVC pipe’s one end connects in cold space at bottom level, and other second end of PVC pipe opens in atmospheric. The second end of PVC pipe, height minimum one feet from ground level of earth surface. The atmospheric air goes into cold space through PVC pipe. The second gate of cold space connected with air preheat chamber of chulha with another PVC pipe. The cold space geometry can be rectangular or circular shape.

|

Experimental set up of modified cooking furnace Click here to View figure |

|

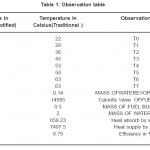

Table 1: Observation table Click here to View table |

Nomenclature

| HCV | High calorific value of fuel |

| LCV | Low calorific value |

| CV Net | Net calorific value (HCV- LCV) |

| hfg | Enthalpy of fluid at gas phase |

| Cp | Specific heat of Material |

| T max | Maximum Temperature in Celsius |

| T min | Minimum Temperature Celsius |

| k j | Kilo Joule |

| kg | Kilo Gram |

Formula Used

Equations and formulae are used to calculate the Performances parameters

- High calorific value of fuel HCV= [33900 Carbon % + 144000(Hydrogen - Oxygen /8) +9290 Sulphur%] kj/kg

- Low calorific value (LCV)=[HVC-9H%*hfg] kj/kg

- Thermal Efficiency of furnace =[Heat absorbed by water/ heat supply by fuel]*100

- Heat absorbed by water =[Mass of water take*Cp*(T max-T min) +Mass of evaporated water*hf g ] k j/kg

- Heat supply by fuel= [Mass of fuel * CV Net of fuel ] kJ/kg

- Fuel used (Eucalyptus wood) chemical component

- Carbon =50%, hydrogen=5.87%, oxygen =43%, nitrogen=0.3%, and sulfur=0.01%

- Effect of moisture, on calorific value of fuel 10% then CV 88%

Calculation of Calorific Value

- Calorific value of wood used HCV= [33900 Carbon % + 144000 (Hydrogen% -Oxygen %/8) +9290 Sulphur%] kj/kg = [33900* 50 % + 144000(5.87% - 43% /8) +9290 *0.01%] kj/kg = [17663.729] kj/kg

- LCV= [HVC-9H%*hfg] kj/kg = [17663.729-9*0.0587*2257] kj/kg = [16471.459] kj/kg Due to moisture content in fuel for 10 % moisture =88% of LCV CVNet= 88% of LCV = [88% of 16471.459] kj/kg= [0.88*16471.459] kj/kgCVNet = [14495] kj/kg

Results

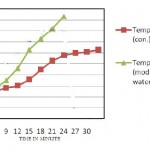

Compression Temp. Rise modified and conventional Chulha.

- There is no environmental pollution occurs due to complete combustion of fuel by use modified chulha.

- There is a best utilization of fuel compared to conventional chulha. The thermal efficiency of modified chulha over the conventional chulha is 7 % more thus it uses the fuel most efficiently.

- The 50 % of less fuel is required to boil the unit mass of water by the modified chulha

- The immediate environment is clean due to the complete combustion of fuel.

- The extra supply of the air from the holes makes modified chulha more efficient.chulha cost is Rs.385/-

|

Chart 1: Observation chart Click here to View chart |

Conclusion

Disadvantages of traditional Indian cooking furnace (chulha)

In the over all study of indoor traditional cooking furnace has these disadvantages.

- High smoke

- Incomplete fuel combustion.

- Low combustion rate of fuel

- Less utilization of heat produced by fuel

- Available Moisturize in combustion air due to use atmospheric air

Advantages of Introduction of modified Indian cooking furnace (chulha)

- Less smoke

- High thermal efficiency

- Easy to make.

- Easy to operate.

- Continuous combustion of fuel.

- Cheapest

- Pupation less.

- Complete combustion of fuel

Future Plan

There is more chance for increase the thermal efficiency for change in cold space, air heat chamber and geometric size of chulha. In that model can be change shape of part (A) chulha in circular shape. Due to circular shape heat after gating the peek point of efficiency it hand over Rural Development department to Government of Madhya Pradesh to implement in rural area. And that concept can be used in industry for furnace.

References

- R.D.Hanbar “International Meeting on Indoor Air Pollution, Fuel-Efficient Stoves and Sustainable Development 16-17 Oct. 2006 Brasilia, Brazil National Program for Dissemination of Improved Cookstoves A Case Study of India and Commercialization project By R.D.HANBAR Appropriate Rural Technology Institute (ARTI) Pune, India.”

- K.S. Pushpa, “Smokeless. Chulha” for National Programme on Improved Chulhas (NPIC) in (1999)

- FAO, “Wood fuel surveys”., UN Food and Agriculture Organization: Rome (1983).

- Kishore, V.V.N. and P.V. Ramana,” Improved cookstoves in rural India: how Improved are they?: Acritique of the perceived benefits from the National Program on Improved Chulhas (NPIC) Energy”, (2002).

- R. K. Rajput “heat and mass transfer” S Chand and company 3RD revised edition 2006

- S.P. Sukhatme “Solar Energy: Principal of Thermal Collections and Storage”, Tata McGraw-Hill, New Delhi (1994).

- G. D. Rai “Non conventional sources of energy”, Khanna Publishers Delhi, (1997).

- Tarun Goyal “General knowledge”Arihant Publication(I) Pvt. Ltd. Meerut (2009).

- A.K. Shaha. “Combustion Engineering and Fuel Technology” Oxford & IBH Publishing Company

- Archer, Cristina L.; “Evaluation of global wind power” Mark Z. Jacobson (2005).

- Arrora ,Domkundwar A Domkundwar “ A Course in heat and mass transfer “ Dhanpat Rai and company (2008).

- B.H. Khan “Non-conventional Energy Resources”, Tata McGraw-Hill Publishing Company Limited, New Delhi (2006).

- C.P. Arora “refrigeration and air conditioning” T M H 4th edition (1999).

- Dovey, Karen. “Energy Alternatives. Farmington Hills, Minassota” Lucent Books, (1962).

- Dr. D.S. Kumar “thermal Science and Engineering” S.K. Kataria & sons Third Enlarged Edition 2005-06

- Duffie and beckman “solar energy and its application” Wiley Interscience, (1974).

- D G Nocera “World per-capita energy use in 2003” 2006

- D. Yogi Goswami, Frank Kreith, “Energy Conversion (Mechanical Engineering)” CRC (2007).

- H.P. Garg, J. Prakesh “solar energy (fundamentals and application)”, Tata McGraw-Hills, New Delhi (1994).

- J H Keenan “thermodynamic” john Willy New York (1941).

- J. Ongena, G. Van Oost. “Energy for Future Centuries” Retrieved 2008" (PDF).

- Kenneth Wark “thermodynamics” McGraw-Hill New-York (1977).

- M.L. Mathur and R.P Sharma and “internal combustion engine” Dhanpat Rai 15th edition (2005).

- Pallava Bagla. “Rethinking Nuclear Power: India’s Homegrown Thorium Reactor” Science (magazine) (2005).

- P. L. Ballney “Thermal Engineering” Khanna Publication 22nd edition (2000).

- P. K. Nag “Engineering thermodynamics” TataMcGraw-Hill Eighth Reprint (1989).

- Price, Trevor J “James Blyth - Britain’s first modern wind power engineer” (2005).

- R.K. Rajput “Thermal Engineering” Laxmi Publicatios(p) Ltd Eighth Edition (2010).

- Suresh Kumar Soni, Manoj Nair “Energy Conservation and Audit” Satya Prakashan New Delhi first Edition (2009-10).