Bioplastic Production Using Aloe vera Gel as Plasticizer: A Sustainable Approach

1

Department of Biotechnology,

Vivekanandha College of Engineering for Women (Autonomous),

Tiruchengode,

Tamil Nadu

India

Corresponding author Email: rajamehala@vcew.ac.in

DOI: http://dx.doi.org/10.12944/CWE.19.2.38

Copy the following to cite this article:

Rajamehala M, Reshma M, Kaniyamudhu V, Shruthika K. Bioplastic Production Using Aloe vera Gel as Plasticizer: A Sustainable Approach. Curr World Environ 2024;19(2). DOI:http://dx.doi.org/10.12944/CWE.19.2.38

Copy the following to cite this URL:

Rajamehala M, Reshma M, Kaniyamudhu V, Shruthika K. Bioplastic Production Using Aloe vera Gel as Plasticizer: A Sustainable Approach. Curr World Environ 2024;19(2).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2024-05-15 |

|---|---|

| Accepted: | 2024-08-27 |

| Reviewed by: |

Ashok Thulluru

Ashok Thulluru

|

| Second Review by: |

Tanmay Sarkar

Tanmay Sarkar

|

| Final Approval by: | Dr. Wilkister Moturi |

Introduction

Petroleum based derivatives are used for the products of plastics that made many drawbacks. In the production process it needs a large amount of energy, as well as Years were needed for it to degrade, and the ecosystem was also put in peril 1. The packaging industries are mostly developed the plastics. Substitution is critical for the plastic bundling business since its evaluated to develop to 22 million tons by 2020 from 13.5 million tons in 2015. Half of the plastics are disposed after the single utilize, in line with the examination by the federation of Indian chambers of commerce and industry. By the petroleum sources these plastics are commonly made off; they’re non-corroding so require substitute source for instance, only a few grams of plastic (such as polyethylene) can take up to one hundred years to deteriorate beneath normal environment conditions. Because plastics be not able to downgrade by natural method in a short stretch of time, they are left as plastic waste, result in environmental issues. Bioplastic can be made many different substances, inclusive of starches, cellulose, or other biopolymers2. There have been biodegradable polymers derived from cellulose and starches for many years; the first demonstration of a cellulose-based polymer, which launched the plastics industry, took place in 1862. Depending on how they are made, composable bioplastics plastics can decompose in either anaerobic or aerobic conditions. Food packaging, dining utensils, insulation, and packaging materials are a few typical uses for bioplastics 3. There is a revived interest in the study of starch-based materials, according to these works and the reference they provide.

Starch is an affordable and plentiful product available in nature. In a wide variety of environments, it is fully decomposable and it can be utilized for the specific needs of market in the development of completely perishable products4. In the field of food technology, engineering, pharmaceuticals, packaging, and agriculture, starch is used extensively these days 5. The biological carbon cycle is closed when starch-producing plants decompose or burn their starch products because they recycle the atmospheric CO2 that the plants captured during growth. The application of cassava starch films showed promise; they looked good, were transparency and shiny, and weren’t sticky. To reduce the postharvest losses, created edible coatings made of cassava starch 6. Cassava starch is made of two polymers amylose and amylopectin. Properties such as granule size, strength of the film, gelatinization, glass transition temperature, and the presence of plasticizers were impacted by high amylose content in starches. Physically and chemically, these two chains differ greatly from one another.

Waste newspapers are become disposed of by being thrown into the ocean, which are mainly consist of cellulose. Here, we are producing bioplastics from waste materials like cassava starch and newspaper waste. Newspapers, which come from the 500,00 trees those are cut down every week and of which 88% are never recycled, are get dumped into the water7.

Benefit of after removing the starch from the discarded cassava, it can be utilized for making biofuel. In addition to providing an economically viable alternative for cassava farming, the use of cassava would lessen the negative effects of the widespread usage of packaging film made of petroleum (polyethylene, polystyrene, etc..). since the goal of this study was to determine how bioplastic starch affected the sheet’s characteristics, the ratio of newspaper pulp to bioplastic was first se at 50% newspaper pulp fibers and 50% bioplastic starch (N50%: B50%), and the bioplastic content was gradually boosted. It was believed that adding fibers to the bioplastic sheets would enhance their functionality 8. After tensile strength testing, the sheets were analyzed for weight changes in water absorption and strength to investigate the properties of bioplastic sheets made from different starch bases mixed with recycled newspaper pulp.

The creation of bioplastic is an entirely distinct function than that of synthetic plastic. After rice and maize, cassava could become the world’s third largest food crop. Starch might be an organic biopolymer. Potential analysis of the developed bioplastic and functional group present within the bioplastic, which can be determine by the use of Fourier-transform infrared spectroscopy (FTIR). The following are some characteristics of biodegradation of bioplastic: loss of weight, change in tensile strength, change in dimensions, change in chemical and physical properties, production of carbon dioxide, change in molecular weight distribution, and bacterial activity in soil 3. These plastic’s qualities of biodegradability have a beneficial effect on society, and industries and researchers are get attracted to recyclable packaging because of its widespread use.

The novelty of this study lies in the innovative use of Aloe vera gel as a plasticizer in bioplastic production, a novel approach that leverages the natural properties of Aloe vera to enhance the flexibility, processability, and biodegradability of bioplastics. Unlike conventional plasticizers derived from non-renewable, petroleum-based sources, Aloe vera gel offers a sustainable alternative, aligning with the growing demand for environmentally friendly materials. The study uniquely combines Aloe vera with Cassava starch, creating a bioplastic blend that is both renewable and abundant, particularly in developing regions. Furthermore, the research stands out by systematically evaluating the mechanical, thermal, and biodegradation properties of the bioplastics, revealing that some formulations not only perform well but also degrade more rapidly in composting conditions. This comprehensive analysis highlights the potential of Aloe vera-based bioplastics for diverse applications, advancing the field with a material that addresses both environmental sustainability and practical performance.

Materials and Methods

Sample Preparation

Biopolymers have been utilized in the food sector to synthesize edible and biobased packaging materials. They have contained edible and food grade additives. Proteins, polysaccharides which are gums or carbohydrates and lipids are some of these kinds of biopolymers. The biopolymers were to be mixed with plasticizers and other additives, and the film's functioning or physical characteristics was to be examined by altering the film properties 9.

Extraction of Starch from Cassava

The cassava has been chopped into a small piece and peeled it before being ground into a paste in a mixer grinder. Afterwards with the help of a filter cloth the grounded cassava has been filtered and the extracted cassava filtrate was combined with water once again and filtered. After the starch mixture was allowed to settle for an hour, it was manually dewatered. Subsequently, the wet starch was exposed to air drying. Then the moisture was removed by drying the starch precipitate, it was crushed out with a mortar and pestle to ensure uniform size 10.

Preparation of Aloe vera Gel

Rather than using glycerol, aloe vera gel was chosen as a plasticizer to create a bioplastic. Then the aloe vera is washed, and the skin is discarded. Then, take an aloe vera gel, and it is washed with water 2 to 3 times. A filter cloth is then used to filter the gel after it has been ground in a mixer grinder 11. 3ml of aloe vera gel were chosen from different concentrations.

Preparation of Newspaper Pulp

To obtain a lingo cellulosic fibrous pulpy material the waste newspaper was segmented into small pieces in the mortar and pestle then it was grinded to obtain a fine paste is known as paper sludge. The procedure preserves the cellulose fibers in the paper while removing lignin, which makes cellulose extraction easier 12.

Preparation of Polymer Film

A weighing balance was used to measure the 3g of cassava starch. Additionally, 20ml of distilled water was heated to 100°C using a heating mantle. Subsequently, 0.5ml of vinegar, 3ml of newspaper extract, and 3ml of aloe vera gel were added to the distilled water and thoroughly mixed. Subsequently, cassava starch was added to the mixture in the heating mantle, and the mixture was constantly stirred for 30 minutes at 100°C using a glass rod. Starch becomes a polymer when heated with vinegar, which aids in the formation of a film. Only the amylose chain remains when the acetic acid in vinegar destroys the amylopectin's cross-linking, and the aloe vera gel acts as a plasticizer to keep the film together.

To create the polymer film, cassava starch, newspaper extract, and aloe vera gel were mixed together. To finally bring all of the components together, the mixture was heated to 100°C until it started to boil. The bubbles were then allowed some time to settle. The edible biofilm is obtained once they are settled and dried. All of the mixture required heating in order to combine and produce the film because they each had unique qualities. After pouring, the viscous result was dried for one or two days at room temperature to create a solid film. The purpose of the drying process was to facilitate the sheet removal. Biodegradable test results were analysed by keeping edible package in open environment to observe its decomposition by the environmental flora and fauna 13.

Result and Discussion

Sample Preparation

Aloe vera gel, vinegar, newspaper extract, distilled water, and cassava starch made from cassava tubers were mixed to create polymer film. Throughout the whole procedure, the temperature of these blended mixture was maintained at 100° C. Subsequently, the resultant liquid was well combined in order to form the polymer film. Vinegar plays a role in removing the cross link of amylopectin, which actually resulted in the starch containing only an amylose chain. The polymer is produced in part by the amylose chain in starch and is mixed with Aloe vera (a plasticizer) 14.

| Figure 1A: Cassava Starch

|

| Figure 1B: Biopolymer Film

|

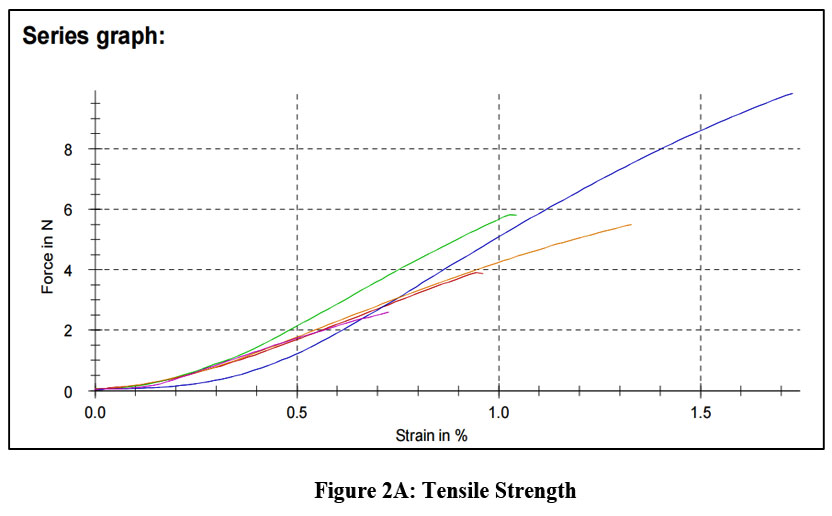

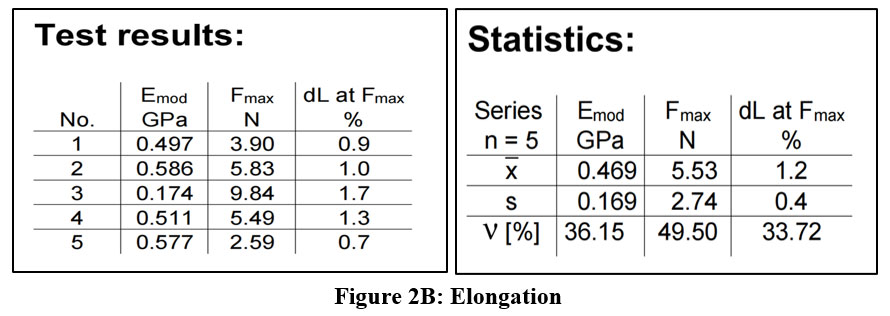

Tensile Strength and Elongation

The experimental procedure was carried out. The conventional technique for analyzing the bioplastic film's tensile properties. The tensile strength was tested using a texture analyzer. The edible film was first made by cutting it, and then each end was secured inside the machine to be dragged in the opposite way. The force required to drag the edible film until it breaks is used to determine its tensile strength. The proportion of the edible film length variation between before and after the texture analyzer drags it is known as elongation. The bioplastic film had a tensile strength of determined to be 5.53 N. Additionally, the percent mean breaking elongation was found to be 1.2%, indicating the extent to which the film can stretch before reaching its breaking point. These findings are crucial for understanding the mechanical properties of the bioplastic film, particularly its flexibility and strength, which are essential considerations for its potential use in packaging applications11.

Thickness

Bioplastics with an even distribution of fibre would have a higher tensile strength after reinforcement Additionally, the tensile strength of bioplastics might be further enhanced by the fibre’s mechanical strength and thickness. The thickness yields a result of 0.05 mm 15.

| Figure 2A: Tensile Strength

|

| Figure 2B: Elongation

|

Soil Burial Test

The produced film's biodegradability was tested using the soil burial method. The manufactured biopolymer utilized in this process was buried for a predetermined period of time, and before and after burying in the ground, its size, biodegradability, and microbe content were evaluated. After that, it is ascertained by visual inspection that the film has been shrunk from its original dimensions. The film was buried in the ground on the first day. The film was buried in soil and examined after three days. The film's size had shrunk, and a test for bacteria and fungi allowed to determine how degradable it was. On the fifteenth day, the film is deteriorated completely 16.

Water Absorption and Solubility

Water absorption and solubility was measured. After the dried sheets were first weighed, they were left in room temperature distilled water for a full day. Twenty percent of the sheet were remained after 24 hours, with the remaining 80% having dissolved. The sheet was then weighed once more 1.

Water absorption percentage (%) = (Wi – Wf) / Wf x 100%

In this case, Wi represents the starting weight (g) prior to submersion in water, and Wf denotes the weight (g) following submersion.

FTIR

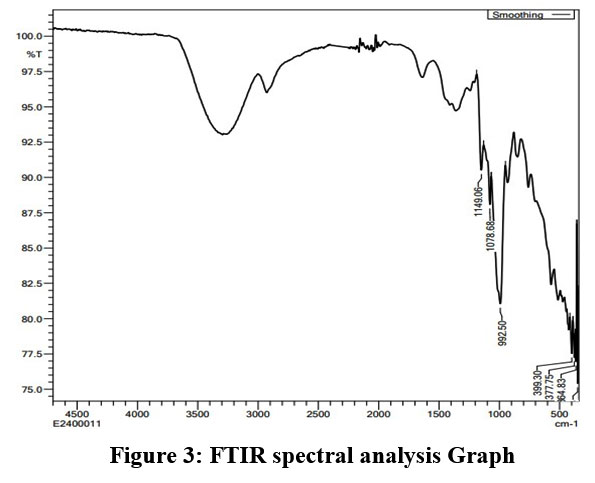

Fourier Transform Infrared, or FTIR, is a characterisation method that uses infrared radiation to pass through a material or sample whose energy matches the wave frequency to observe how the atoms or molecules vibrate. Film component interactions are assessed using Fourier Transform Infrared Spectroscopy. It is a tool for analysis that gives details about the functional groups on the biopolymer film's surface. FTIR is commonly used to measure the emission or absorption of solid, liquid, or gas, as well as to obtain an infrared spectrum. FTIR sticks to broad band spectrum rather than sticking to a narrow frequency of the band. FTIR is a notable study as they throw light on acquiring deep knowledge about the compounds and molecules like 38 hydrogen and oxygen or any other chemical bonds that determine the reaction between them. Peak intensity and wavenumber variations give qualitative information about the chemical modification of the polymeric structure.

The most important diagnostic peaks are seen in the wavenumber range of 4500 cm-1 to 500 cm-1, which is represented by the spectra in Figure 3. The principal peaks are recorded at 1149.06 cm-1, 1078.68 cm-1, and multiple other smaller peaks. In the presence of a plasticizer, the graph shows a shifting peak towards a higher wavenumber 17.

|

Table 1: The peak details of FTIR spectrum Analysis

S.NO | PEAK NUMBER | FREQUENCY RANGE (cm) | FUNCTIONAL GROUP | PEAK INTENSITY |

1 | 1149.06 | 1300-1150 | Alkyl halides included in the C-H wag(-CH2X) stretching vibration | Strong intensity |

2 | 1078.68 | 1250-1020 | The presence of aliphatic amines in the C-N stretching vibration | Medium intensity |

3 | 992.50 | 1000- 910 | Presence of primary and secondary amines in N-H wag stretching vibration | Strong intensity |

4 | 399.30 | ~500 | Alkyl halides present in the C-Br stretching vibration | Strong intensity |

5 | 377.75 | ~500 | Alkyl halides present in the C-Br stretching vibration | Strong intensity |

6 | 354.83 | ~500 | Alkyl halides present in the C-Br stretching vibration | Strong intensity |

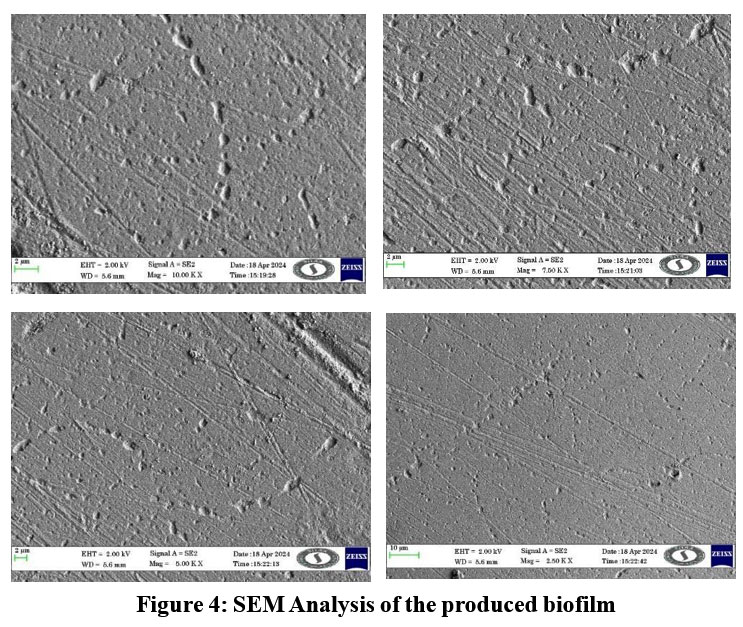

SEM (Scanning Electron Microscope)

To determine whether the mixtures are thoroughly mixed during the polymerization process, SEM can be used to determine the molecular structure of the sample. The morphology of a material like corrosion, damage, contamination, or any other surface discontinuity can be done by using Scanning Electron Microscope (SEM). Applying a drop coating of a biologically generated packaging film while the machine ran at a 25 kV accelerating voltage allowed for the execution of SEM measurements14. The composite materials were positioned on a carbon stub prior to the acquisition of scanning electron images. The samples with the same fibre loading exhibit negligible differences in the SEM images. The bagasse-infused material has pore-free, smoother surfaces, and with a compact structure can be observed. A reliable measure of the films' structural integrity is the homogeneity of their matrix. As a result, it makes sense that films made of bagasse would have superior mechanical qualities. Increased filler content causes the particle density to rise, which encourages filler particle interaction and may lead to the formation of aggregates. Due to the large fiber size and the existence of these aggregates, matrix defects affect the integrity of the film structure. The peel-exhibiting films showed less smooth surfaces, a uniform texture, and a rough texture with visible pores dispersed randomly across the network, especially with increasing loads. The mechanical strength of the composites is lowered by undesirable fiber agglutinations, which restrict the stress transfer from the matrix to the fiber 17.

| Figure 4: SEM Analysis of the produced biofilm

|

The above pictures were recorded as the results of the SEM analysis of bioplastic film at various magnifications like 10.00 K X, 7.50 K X, 5.00 K X, 2.50 K x, 1.00 K X, 500 X, 250 X, 125 X. The image shows that there is a heterogeneous microstructure present. The material's primary evidence consists of a few circular patches that are likely composed and have dimensions between a few hundred nm and several thousand nm. The voids and the separation present in the images are directly proportional to the plasticizer. The Fig 4 shows that the presence of voids and distortions are due to the higher plasticizer content present.

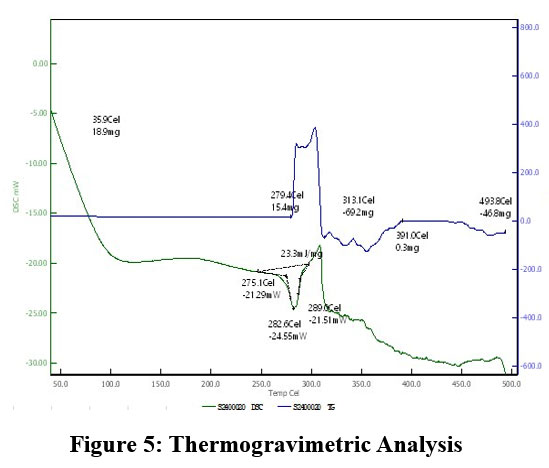

TGA (Thermogravimetric Analysis)

Thermogravimetric analysis (TGA) is an analytical method that observes the weight changes of samples heated at a constant rate in order to determine the percentage of volatile components in materials and their thermal stability. The measurement is usually performed in air or in an inert environment like helium or argon. The weight is calculated based on a rise in temperature. The thermal deterioration of films based on aloe vera starch has been the subject of numerous investigations employing thermogravimetric analysis (TGA)18 and the result is depicted in Fig 5.

| Figure 5: Thermogravimetric Analysis.

|

The present research comprises implications and supports a lower carbon footprint, reduces plastic pollution and also suitable for low-durability uses like packaging. Limitations of bioplastic have dependence on the agricultural production of cassava and aloe vera can lead to supply issues. Seasonal variations and climate conditions affect yield crops. These bioplastics can be more susceptible to water absorption and degradation. The initial cost setting up bioplastic production facilities can be high. Continued research and development can lead to improvements in the bioplastic properties, making them more competitive with conventional plastics.

Table 2: Comparison between Conventional Plastic and Produced Bioplastic

Attribute | Conventional Plastic | Bioplastic from Cassava Starch & Aloe Vera Gel |

Raw Material | Petroleum-based (e.g., polyethylene, polypropylene) | Natural, renewable (Cassava starch and Aloe vera gel) |

Biodegradability | Non-biodegradable; persists for hundreds of years | Biodegradable; decomposes in composting conditions |

Environmental Impact | High carbon footprint, contributes to plastic pollution | Low carbon footprint, reduces plastic waste |

Tensile Strength | Generally high, varies depending on type (e.g., 20-40 MPa for LDPE) | Lower than conventional plastic (e.g., 5.53 N for the study's bioplastic) |

Elongation at Break | High elongation, especially in flexible plastics (e.g., 200-800% for LDPE) | Lower elongation (e.g., 1.2% for the study's bioplastic) |

Thermal Stability | High, suitable for a wide range of temperatures | Moderate; some formulations show enhanced thermal stability |

Thickness | Variable, typically thicker for durable applications | Thin (e.g., 0.05 mm as in the study) |

Processability | Well-established, suitable for mass production | Processable; enhanced with Aloe vera gel for better flexibility |

Cost | Generally low due to large-scale production | Potentially higher but can be reduced with widespread adoption |

Availability | Widely available, global production infrastructure | Regionally dependent, particularly on the availability of Cassava and Aloe vera |

End-of-Life Disposal | Incineration, landfill, recycling (with challenges) | Composting, biodegradation, minimal environmental residue |

Toxicity | Can release harmful chemicals when degraded or burned | Non-toxic, biocompatible |

Sustainability | Low, relies on fossil fuels | High, utilizes renewable resources |

Application Suitability | Suitable for a wide range of applications (packaging, construction, etc.) | Suitable for applications where biodegradability is a priority (e.g., packaging, disposable items) |

Conclusion

The research paper on the utilization of Aloe vera gel as a plasticizer in bioplastic production presents a compelling case for the development of sustainable and eco-friendly alternatives to traditional plastics. By incorporating Aloe vera gel into the biopolymer film, the study demonstrates significant improvements in biodegradability, water absorption, and solubility, highlighting the potential of Aloe vera gel as a crucial component in the quest for environmentally friendly packaging solutions. One of the key findings of the study is the enhanced biodegradability of the biopolymer film when Aloe vera gel is used as a plasticizer. Through soil burial tests, it was observed that the film degraded completely within a relatively short period, indicating its ability to break down naturally in the environment. This is a crucial aspect in the context of reducing plastic pollution and mitigating the harmful impact of non-biodegradable plastics on ecosystems. Moreover, the water absorption and solubility tests revealed that the biopolymer film containing Aloe vera gel exhibited a significant level of water absorption, with 80% of the film dissolving after 24 hours. This property can be advantageous in applications where water solubility is desired, such as in single- use packaging that can be easily disposed of without causing environmental harm. The use of Aloe vera gel as a plasticizer also influenced the mechanical properties of the bioplastic film, as evidenced by the tensile strength and elongation tests. The film displayed a tensile strength of 5.53

N, indicating its ability to withstand certain levels of stress before breaking. This suggests that Aloe vera gel not only enhances biodegradability but also contributes to the overall durability and functionality of the bioplastic material. Furthermore, the study underscores the importance of utilizing natural and renewable resources, such as Aloe vera gel, in the production of bioplastics. By harnessing the properties of Aloe vera gel, a plant-derived substance known for its various health and skincare benefits, the research highlights the potential for creating sustainable packaging materials that are both effective and environmentally friendly8.In conclusion, the incorporation of Aloe vera gel as a plasticizer in bioplastic production represents a significant step towards developing innovative and sustainable solutions to the global plastic pollution crisis. The study's conclusions offer insightful information about how natural components might improve the biodegradability and functionality of bioplastics. paving the way for a more sustainable future in packaging and materials science. By continuing to explore the possibilities offered by nature's resources, we can strive towards a greener and more environmentally conscious approach to plastic production and waste management.

Acknowledgment

We would like to express our gratitude to department of Biotechnology, Vivekanandha College of Engineering for Women for providing laboratory facilities for the whole research.

Funding Sources

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

Data Availability Statement

All data underlying the results are available as part of the article and no additional source data are required.

Ethics Statement

This research did not involve human participants, animal subjects, or any material that requires ethical approval.

Authors’ Contribution

All the authors involved in reviewing and preparing the content for the review article.

References

- Faruqy R, Chang K. Properties of bioplastic sheets made from different types of starch incorporated with recycled newspaper pulp. Trans Sci Technol. 2016;3(2):257-264. http://tost.unise.org/pdfs/vol3/no1_2/31-2_257_264.pdf

- Anitha R, Jayakumar K, Samuel GV, Joice ME, Sneha M, Seeli DS. Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future †. Eng Proc. 2024;61(1):1-5. doi:10.3390/engproc2024061030

CrossRef - Nagar M, Sharanagat VS, Kumar Y, Singh L. Development and characterization of elephant foot yam starch–hydrocolloids based edible packaging film: physical, optical, thermal and barrier properties. J Food Sci Technol. 2020;57(4):1331-1341. doi:10.1007/s13197-019-04167-w

CrossRef - Mohd Nizam NH, Mohammad Rawi NF, Mhd Ramle SF, et al. Physical, thermal, mechanical, antimicrobial and physicochemical properties of starch based film containing aloe vera: a review. J Mater Res Technol. 2021;15:1572-1589. doi:10.1016/j.jmrt.2021.08.138

CrossRef - Ali A, Yu L, Liu H, Khalid S, Meng L, Chen L. Preparation and characterization of starch-based composite films reinforced by corn and wheat hulls. J Appl Polym Sci. 2017;134(32):1-9. doi:10.1002/app.45159

CrossRef - Ezeoha SL. Production of Biodegradable Plastic Packaging Film from Cassava Starch. IOSR J Eng. 2013;3(10):14-20. doi:10.9790/3021-031051420

CrossRef - Novisa S, Nugroho BB, Budiastuti H, Manfaati R. Characterization and Production of Biodegradable Plastics from Cassava Rubber Starch and Old Newsprint Using Glycerol Plasticizer. 2020;198(Issat):23-26. doi:10.2991/aer.k.201221.005

CrossRef - Liew KC, Khor LK. Effect of different ratios of bioplastic to newspaper pulp fibres on the weight loss of bioplastic pot. J King Saud Univ - Eng Sci. 2015;27(2):137-141. doi:10.1016/j.jksues.2013.08.001

CrossRef - Maulida, Siagian M, Tarigan P. Production of Starch Based Bioplastic from Cassava Peel Reinforced with Microcrystalline Celllulose Avicel PH101 Using Sorbitol as Plasticizer. J Phys Conf Ser. 2016;710(1). doi:10.1088/1742-6596/710/1/012012

CrossRef - Murthy K, Ghorpade C V, S SK, Charitha Shetty M SM, J CC, Krishna Murthy TP. Bioplastics Production and Applications: A Mini Review. IJSRD-International J Sci Res Dev. 2022;10(2):2321-0613. www.ijsrd.com

- Affandi MSS, Utomo AR, Setijawaty E, Darmoatmodjo LMYD, Jati IRAP. The development of Aloe vera-based edible film with the addition of sago starch and glycerol for food packaging. IOP Conf Ser Earth Environ Sci. 2023;1200(1). doi:10.1088/1755-1315/1200/1/012046

CrossRef - Joshi, S., Sharma, U., Goswami G. Bio-Plastic From Waste Newspaper. Interntional J Eng Res Technol. 2014;2:24.

- Faradina S, Sedayu BB, Nur M, Fransiska D, Syamani FA. Properties of agar/cassava starch films manufactured by hot-melt extrusion method. Green Mater. 0(0):1-9. doi:10.1680/jgrma.23.00049

CrossRef - Sauvé S, Bernard S, Sloan P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ Dev. 2016;17:48-56. doi:https://doi.org/10.1016/j.envdev.2015.09.002

CrossRef - Liu M, Tong S, Tong Z, Guan Y, Sun Y. A strong, biodegradable and transparent cellulose-based bioplastic stemmed from waste paper. J Appl Polym Sci. 2023;140(13):e53671. doi:https://doi.org/10.1002/app.53671

CrossRef - Nissa RC, Fikriyyah AK, Abdullah AHD, Pudjiraharti S. Preliminary study of biodegradability of starch-based bioplastics using ASTM G21-70, dip-hanging, and Soil Burial Test methods. IOP Conf Ser Earth Environ Sci. 2019;277(1). doi:10.1088/1755-1315/277/1/012007

CrossRef - Amira Othman S, Nursyakirah S, Chui Nee F, Amirah Elias N, Nursyakirah Idris S, Ashiqin Mohd Najib I. Characterization of Bioplastic from Cassava Peel Using Fourier Transform Infrared (FTIR) Spectroscopy. Multidiscip Appl Res Innov. 2022;3(5):118-121. https://doi.org/10.30880/mari.2022.03.05.017

- Sangian HF, Maneking E, Tongkukut SHJ, et al. Study of SEM, XRD, TGA, and DSC of Cassava Bioplastics Catalyzed by Ethanol. IOP Conf Ser Mater Sci Eng. 2021;1115(1):012052. doi:10.1088/1757-899x/1115/1/012052

CrossRef