A Review Paper on Assessing the Environmental Impact of Recycled Aggregate Production and Use

1

Department of Civil Engineering,

SND College of Engineering and Research Centre,

Yeola,

Maharashtra

India

2

Department of Civil Engineering,

Sandip University,

Nasik,

Maharashtra

India

3

Department of Civil Engineering,

K.B.S’S College of Engineering and Technology,

Jalgaon,

Maharashtra

India

Corresponding author Email: pravin.nikam@sndcoe.ac.in

DOI: http://dx.doi.org/10.12944/CWE.18.3.18

Copy the following to cite this article:

Nikam P. A, Dwivedi A. K, Ahirrao S. P. A Review Paper on Assessing the Environmental Impact of Recycled Aggregate Production and Use. Curr World Environ 2023;18(3). DOI:http://dx.doi.org/10.12944/CWE.18.3.18

Copy the following to cite this URL:

Nikam P. A, Dwivedi A. K, Ahirrao S. P. A Review Paper on Assessing the Environmental Impact of Recycled Aggregate Production and Use. Curr World Environ 2023;18(3).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-05-11 |

|---|---|

| Accepted: | 2023-11-30 |

| Reviewed by: |

David Daneesh Massey

David Daneesh Massey

|

| Second Review by: |

Eman H. Khader

Eman H. Khader

|

| Final Approval by: | Dr. R. K. Aggarwal, |

Introduction

One of the most pressing concerns facing the globe today is how to manage the garbage that is contributing significantly to environmental problems. Construction and Demolition Wastes, agricultural waste, glass, and plastic waste make up the majority of this waste 1. Less waste ends up in our landfills the more we recycle. Recycling offers several benefits. That goes beyond merely reducing the amount of trash dumped at dump sites. Recycling provides economic and social advantages in addition to environmental ones 2 . Concrete removed from out-dated structures and roads is typically judged obsolete and dumped as demolition waste. Recycled concrete aggregate (RCA) is produced by assembling leftover concrete and chopping it up. In particular, coarse recycled concrete aggregate (RCA), the coarse aggregate acquired derived from the primarily concrete after separating the mixture and rock for reuse, is the subject of this review. India was the world's second-largest cement producer in 2019. The country owned around 8% in terms of installed capacity globally that year. At this time, there were about 328 million metric tonnes of cement consumed. The commercial sector currently controls 98 percent of the market's manufacturing capacity. The need for cement will probably increase in the future years. This also increased the production capacity that was already established. The material's primary users in 2019 were housing and real estate, which accounted for more than 60% of domestic demand 3 . According to the Building Material Promotion Council (BMPTC), India generates 150 million metric tonnes of building and razing (C&D) garbage every year. However, the official capacity to recycle is a measly 6,500 tonnes per day (TPD), or just 1% 4. it is still a comparatively recent approach to apply RCA in applications for new construction 2 making building more "green" and environmentally friendly is one of the key justifications for using RCA in structural concrete 2 .Comparing the traits in this section of RCAs and NAs. Recognising how change aggregates after being utilized in concrete can help explain why Recycled concrete aggregate might perform in a different way than NA when applied in fresh concrete. The density, water absorption capacity, and porosity of the aggregate, as well as its form and gradation, as well as its resistance to crushing as well as abrasion, are the main aggregate characteristics that are discussed 2 .In this study, the author compares several methods for estimating the capacity of recycled aggregates (RAs) to absorb water and attempts to provide alternatives for a better approach to measure it by highlighting benefits and deal with it effectively5. The application of RAs as a partial or complete substitute for materials from nature could boost the long-term sustainability of proposed projects 6 .

.jpg) | Figure 1: State wise per capita solid waste generation 7

|

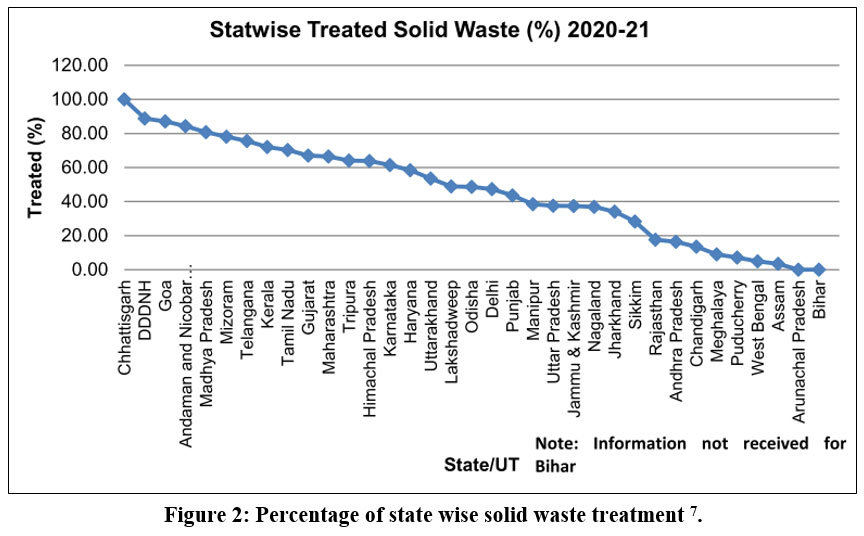

| Figure 2: Percentage of state wise solid waste treatment 7.

|

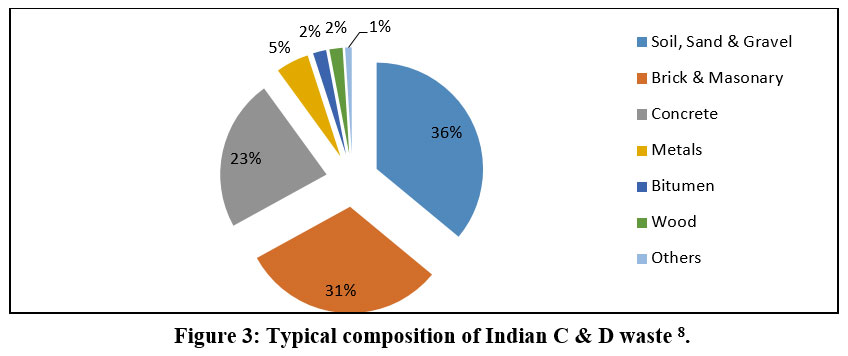

| Figure 3: Typical composition of Indian C & D waste 8.

|

| Figure 4: Indiscriminate dumping of C & D wastes along roadsides 8.

|

Table 1: Conclusions from research articles

| Author | Conclusion |

| M. C. Limbachiya, T. Leelawat, and R. K. Dhir 2000 |

|

| Oikonomou 2005 |

|

| Akash Rao, Kumar N. Jha, and Sudhir Misra a 2007 |

|

| Shi Cong Kou, Chi Sun Poon, and Dixon Chan 2007 |

|

| Chi-Sun Poon and Dixon Chan 2007 |

|

| (Katrina McNeil and Thomas H.-K. Kang 2013 |

|

| Jianzhuang Xiao and Tao Ding 2013 |

|

| Miquel Joseph et al. 2015 |

|

| González-Taboada et al. 2016 |

|

| (Sherif Yehia and Akmal Abdelfatah 2016 |

|

| (M. Quattrone et al. 2016 |

|

| S. Vaishnavi Devi et al. 2020 |

|

| Fernando A. N. Silva et al. 2021 |

|

Concrete Aggregates

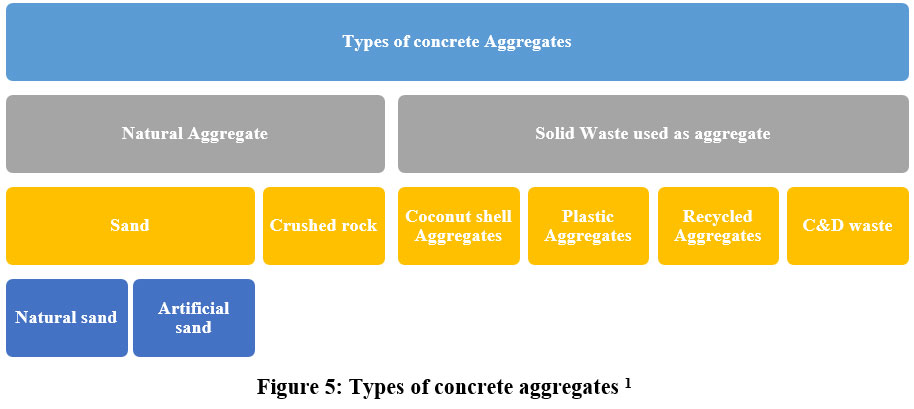

In order to create concrete, granular materials like sand and crushed stone are combined with cement. Since aggregate is quite cheap and doesn't engage in complicated chemical interactions with water, it has traditionally been used as inert filler in concrete. Around 60 to 80 present of the mix for concrete is made up of aggregates. They give concrete bulk and compressive strength. To create an appropriate concrete mix, aggregates have to be free of taken in chemicals, the earth coverings, and any other fine impurities that might cause concrete to decay9. Types of concrete aggregates are listed in Fig 5.

| Figure 5: Types of concrete aggregates 1

|

Natural aggregate

Crushed rock and sand produced artificially by bedrock crushing or naturally occurring unconsolidated sand and gravel make up natural aggregate 10. When compared to the manufacturing of other building materials like steel and cement, the extraction and processing of natural aggregates (such as sand and gravels) often costs less money and uses less energy 11.

| Figure 6: Benefits of Natural Aggregates 12

|

Types of waste used as aggregates

Coconut shell Aggregates

When used as an origin of aggregate in creation of concrete, coconut shells serve the objective of controlling the waste produced by these shells, minimising environmental damage, reducing the possible use of natural resources, and preserving sources. This study examines the intrinsic features of materials such as density, both compressive ability and workability when aggregates partially replaced by coconut shell. Because of its intrinsic qualities, such as adaptability, affordability, durability, and simplicity of production, cement concrete is a key component in the building industry. Consequently, the use of some commercial and agricultural waste has gained popularity recently. The coconut's shell, which has a density of roughly 1.6 g/cm3, and a particle size range of 20 mm to 600 microns, can be utilized as a reinforced material, aggregate, or powder. Due to their increased modulus stiffness, these shells can be utilized as an external agent to improve the characteristics of concrete 1.

Plastic Aggregates

Plastic has a very low biodegradability; as a result, it can stay in the earth's crust for up to thousands of years and its amount gradually rises and is eventually stored in large quantities, creating disposal issues that lead to water and land pollution and make it difficult to break down non-recyclable thin plastic waste globally. Around 15% of all plastic garbage is still untreated today. The behaviour of non-recyclable garbage was examined in a number of studies to determine the alterations in the characteristics of concrete when it was employed as a substitute for aggregates, the use of this waste in concrete aids in environmental management. By only using this powdered form of plastic, the system's tensile strength may be improved. Contrary to typical cement concrete, the use of plastic as aggregate in concrete lowers its compressive strength. Therefore, when loads are minimal, such as at drainage boundaries, street roadways, etc., plastic may be selected 1.

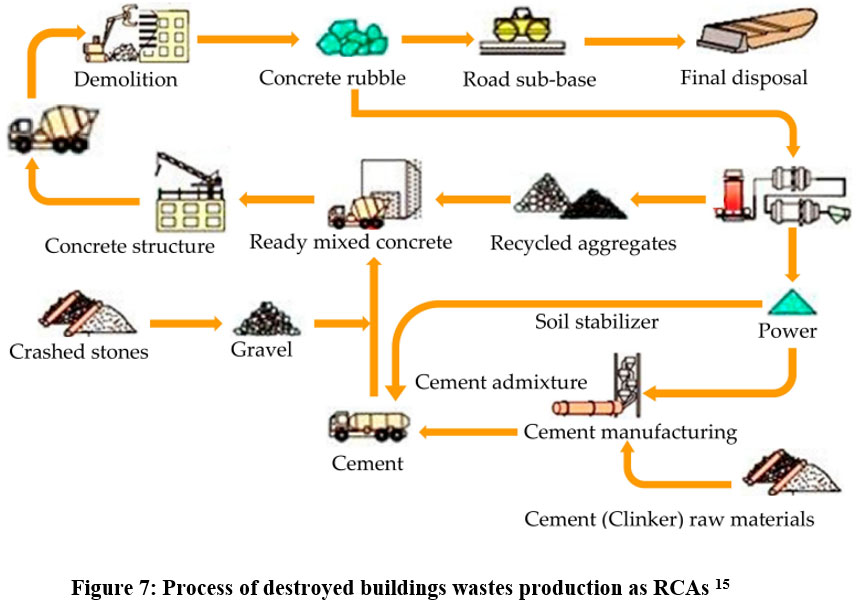

Recycled Aggregates (RA)

When materials that were first utilized in building are processed again, recycled aggregates are created. Asphalt, crushed stone, sand and gravel are some of them. In essence, the phrase describes supplies that have already been employed in building. To make sure the aggregates comply with legal criteria, a reprocessing procedure involving crushing and mixing is needed13.The removed concrete from demolished buildings and roadways is frequently discarded as demolition trash (C&D Waste) since it is thought to be useless 14 .Although they have a lower specific gravity and more porosity than natural aggregates, recycled aggregates share many characteristics with them. They might need more water to function properly. Recycled aggregates of the highest calibre exhibit favourable impact and crushing properties. While total replacement may cause a reduction in strength of up to 28%, partial replacement (up to 40%) has no impact on strength. Additionally, there may be improvements in workability, drying shrinkage, creep, elastic modulus, and water absorption. For the construction of roads, bridges, and substructures, recycled aggregates may be used 1.

| Figure 7: Process of destroyed buildings wastes production as RCAs 15

|

Benefits of using recycled aggregates

| Figure 8: Benefits of Recycled aggregate Aggregates 13

|

Cost effective

Recycled aggregates lower price is another tempting feature, but this does not need you to sacrifice quality. They will meet the exact same standards as the fresh quarry goods. Another thing to consider is that transportation costs will go down if the recycled aggregates are produced locally 13.

Eco-friendly

In the construction industry's effort for lower emissions, recycled aggregates are seen as being both ecologically advantageous and essential to the development and expansion of the sector. Because they can mimic cement and concrete, they are incredibly adaptable. The ecosystem is severely harmed by gravel mining, which uses a lot of resources. To create place for excavating, all vegetation must be removed in order to dispose of the extra sand and gravel needed for construction. Continued mining is less necessary as a result of the recycling of gravel from construction projects 13 .

Recycled aggregates applications

Crushed aggregate in large pieces can be used for a variety of basic bulk fills, as well as the foundation or fill for drainage projects and road building. The crushed aggregate can subsequently be utilized for a number of applications, such as concrete for pavements, curbing, and bridge foundations, following the removal of pollutants by a selective process of screening, air separation, and size reduction 13.

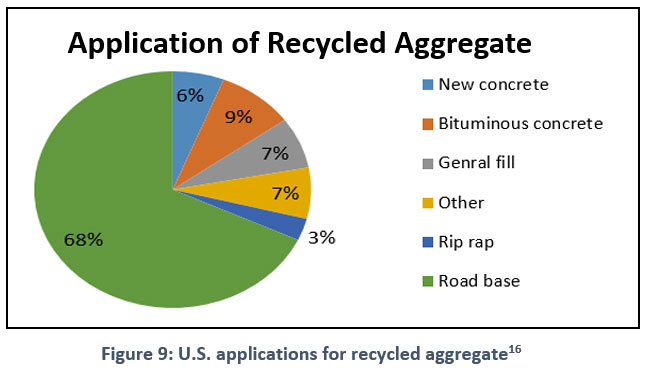

Sustainability

Recycling concrete minimises the quantity of waste going to landfills, and any extra material that may be buried there, such metal, may also be recycled. The requirement for "natural aggregate" is decreased by using this recycling technique for the aggregate. This lessens the effect of the aggregate extraction procedure 13. The material usage breakdown for different construction tasks is shown in the table 2. It lists the percentages of various materials used in these tasks, including road base, rip rap, general fill, bituminous concrete, and new concrete. Interestingly, road base makes up 68% of the materials utilized; the remaining elements are distributed in smaller amounts, from 3% to 9%, for particular building uses. A brief summary of how resources are allocated in building projects is provided by this table 2 as per author maximum application of recycled aggregate in United states is used for road base so we have scope to increase use of aggregate for new concrete and research need to focus to word this which is useful to reduce high cost of basic building material such as dust, artificial fine aggregate, coarse aggregate 16.

Table 2: U.S. applications for recycled aggregate16

Particular work | New concrete | Bituminous concrete | Genral fill | Other | Rip rap | Road base |

% used | 6 | 9 | 7 | 7 | 3 | 68.0 |

| Figure 9: U.S. applications for recycled aggregate16

|

Aggregate Properties

The leftover mortar that is adherent to the RCA has the biggest impact on aggregate characteristics2 .the adhering mortar is the primary distinction between NA and RCA. The total amount of the substance declines with the quantity, size, and original waste quality of crushing procedures17. The whole strength of concrete is impacted by selecting the proper size and grade of aggregates. The aggregates are separated into different grades after being extracted from the natural resources. Aggregate grading makes it easier to choose the best aggregates to any construction project 12

| Figure 10: Aggregate Properties of RCA or NA 2

|

Methodology

In order to thoroughly examine all aspects of recycled aggregates in concrete, a thorough literature analysis was done for this review paper. The literature analysis clarifies the importance of porosity, density, and water absorption qualities in sustainable construction methods. Aspects of shape and gradation are also covered in detail, offering important insights into the structural integrity of concrete that contains recycled particles. Additionally, these materials' reactions to crushing and L.A. abrasion are examined. Evaluation of the impact of recycled aggregates on important mechanical parameters such as modulus of rupture, elasticity, splitting tensile strength, and compressive strength is a major emphasis of this paper. This review's conclusion provides a complete resource for professionals and academics in the field of concrete technology by synthesising important results and trends in the literature.

| Figure 11 Methodology

|

Results and Discussion

Porosity, Density, and Water Absorption

As a result of porosity is due connected cement paste, RCA had a relative density that was 7 to 9% lower and a water absorption that was two times higher than natural aggregates in saturated surface dry states18. The aggregate qualities are mainly affected by the mortar residue on RCA. Due to this, RCA is more porous, less dense, and capable of absorbing more water than NA 2 .when recycled coarse aggregate is substituted for natural coarse aggregate in concrete that is M35, M40, and M45 grade, the water absorption and sorptivity are reduced. Following that, a rising trend may be seen in the water absorption and sorptivity19 .because concrete recovered from demolition work is a diverse material; many coarse recycled concrete aggregates (CRCA) parameters have higher standard deviations. Water absorption is one of the crucial characteristics of CRCA that must be considered when designing concrete mixes, however due to its heterogeneous makeup, it is difficult to forecast how much water will actually be absorbed by CRCA during the mixing process, For the industry CRCA water absorption fluctuation is a problem, It may be possible to find a remedy by adapting the traditional WA procedure (long-term soaking, towel wiping, and drying). However, in the production of concrete, 30 minutes of soaking is adequate 20. Water uptake of RA Ranging between 2.8% - 5.9%, with a wide variation according to source variation 6 Only workability loss results from water absorption underestimate, and this may be remedied by increasing the amount of super plasticizer 20. Mathematical artefacts can overcome these issues, but they must be calibrated using experimental data established by routine testing throughout time. Because the WA kinetics are likely to vary when RAs come into contact with cement paste, a way to comprehend and quantify this phenomena remains a research need5. The density of RCA declines with increasing size and is lower than that of NA. The mortar that has been attached is responsible for this decline. The average density of recycled sand is 2312 kg/m3, but the average density of coarse RA for concrete is 2437 kg/m3 17.

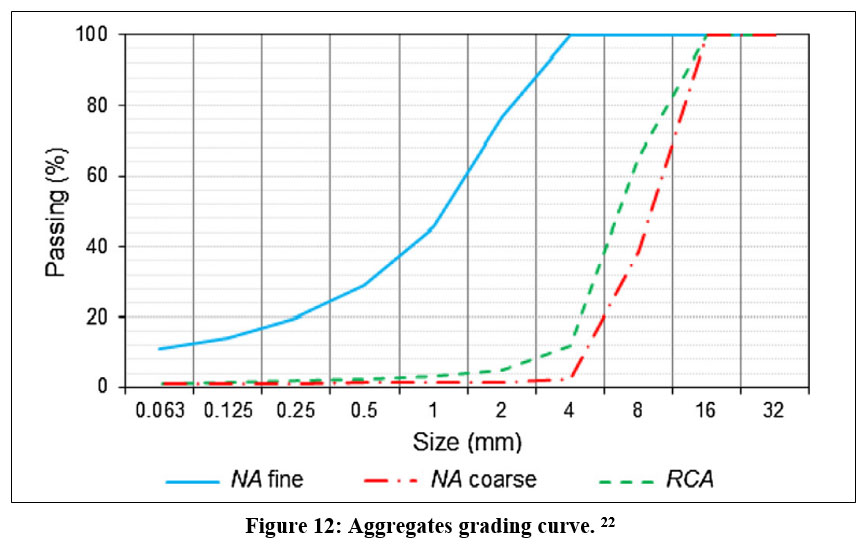

Shape and Gradation

Overall, RCA was shown to be rougher, porous, and these mixes water and coarse aggregate contents are rougher but equal-dimensional when compared to NA According to BS 882, the crushed-rock aggregate's grade was within acceptable ranges 18. While the gradation of RCA and NA particles is comparable, the structure of RCA particles is more rounded, and more fines are broken off 2 .Regardless of location, recycled aggregate gradation is properly graded 6 . Comparable to NCA, recycled concrete-based CA grades similarly. However, recovered sand can be coarser than the natural fine aggregate. Researchers also agree that recycled concrete aggregate has a significant degree of surface roughness, which affects the loss of workability in concrete 17.

| Figure 12: Aggregates grading curve. 22

|

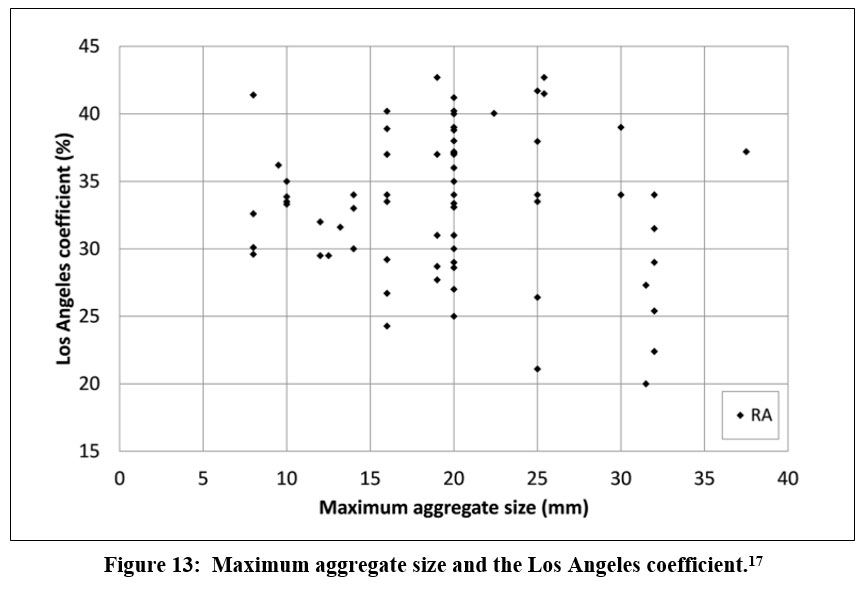

Crushing and L.A. Abrasion

The behaviour of RCA in tests for abrasion and crushing reveals the vulnerability of the adhering mortar. The mortar layer that is bonded to the aggregate is projected to weaken the connection within concrete because this layer is more probably separate from aggregate2. The crushing value and L.A. abrasion of recycled aggregate are within acceptable limits 6. The recycled concrete aggregate has a greater Los Angeles coefficient than natural aggregate. As water is absorbed, it expands, and as density and the maximum aggregate size increase, it contracts. Using the database, it was found that used concrete coarse aggregate with a 7% water absorption value resulted in a Los Angeles factor under 42% 17.

| Figure 13: Maximum aggregate size and the Los Angeles coefficient.17

|

RCA Concrete Material Properties

It has been demonstrated that high-strength RCA concrete will perform similarly in terms of engineering and durability to concrete manufactured with natural aggregates18.

| Figure 14: RCA Concrete Material Properties2

|

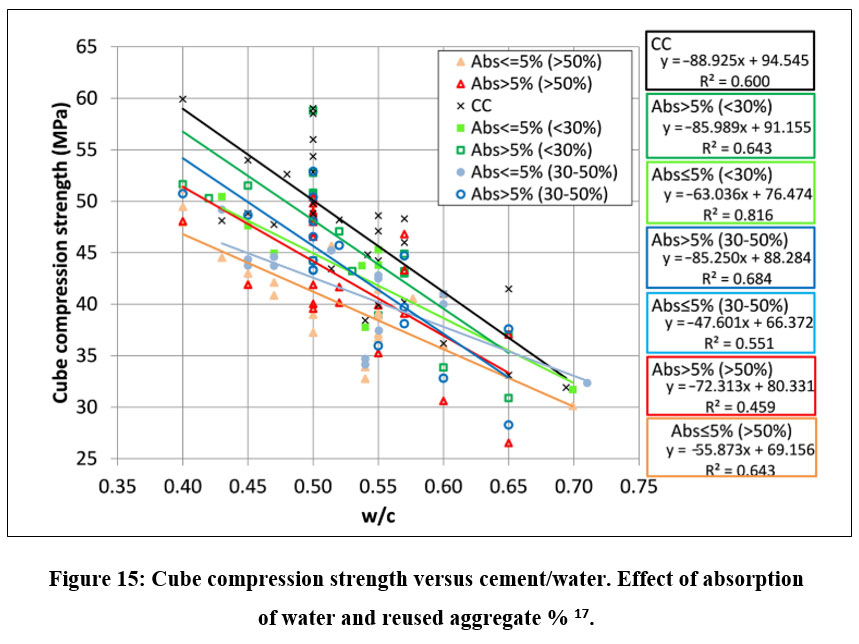

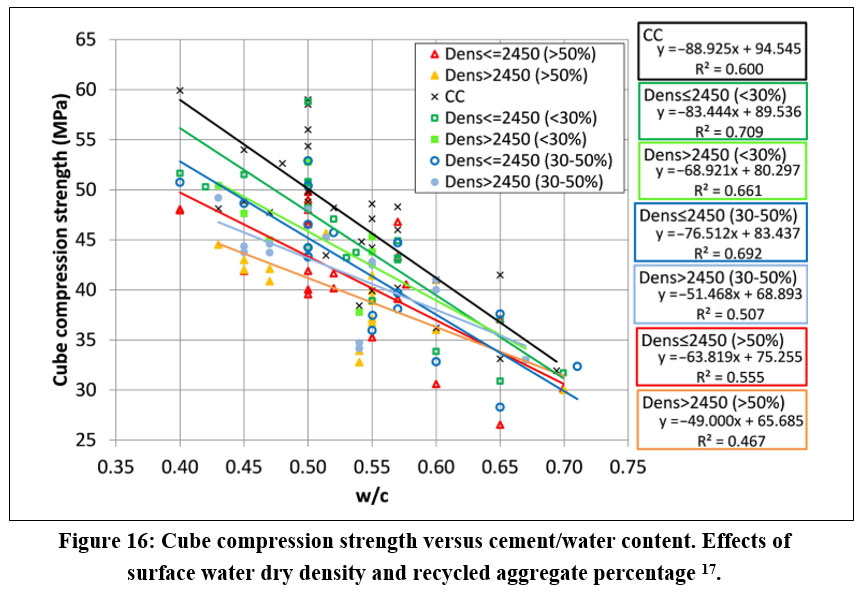

Compressive Strength

The findings demonstrated that coarse RCA having no influence on the strength of concrete up to 30%, whereas the RCA concentration grew, there was a steady loss of strength18. The common patterns seen suggest that coarse RCA may be utilized in a number of high in strength concrete blends with good compressive strength 18. As the recycled aggregate content raised, the compressive strength dropped23.Compressive strength is decreased when NA is substituted for RCA in concrete 2. With the addition of RA, compressive strength tends to drop, however the inclusion of super plasticizers can improve the mix's compactness, making up for the majority of the strength loss24 . Compressive strength studies have revealed that when the replacement percentage increases, the strength decreases. Still, the use of the RA has no effect on strength as water cement ratio is greater than 0.6. In these situations, impact of new the cement paste poor quality is higher than the existence of RA 17.

| Figure 15: Cube compression strength versus cement/water. Effect of absorption of water and reused aggregate % 17.

|

| Figure 16: Cube compression strength versus cement/water content. Effects of surface water dry density and recycled aggregate percentage 17.

|

Splitting Tensile Strength

As the recycled aggregate content raised, the tensile splitting strength, dropped23. Replacing NA in concrete with RCA, while producing similar or better tensile strength for splitting 2. The decrease in flexural rigidity compared to the baseline mix was nearly constant at all percentage replacement levels, similar to the tensile strength of splitting tests. In comparison to the baseline mixture without RCA, the six mixes' average loss in flexural strength was 9.2%. 25.

Modulus of Rupture and Elasticity

Elastic modulus and flexural strength However, it was discovered that the concrete's RCA concentration increased shrinkage and creep stresses18. The static modulus of elasticity decreased as the amount of recycled aggregate increased 23. The modulus of rupture of concrete made with RCA was a little lower than that of conventional concrete because residual mortar reduced the interfacial transition zone. The more ductile aggregate results in a lower-than-expected modulus of elasticity2 .The modulus of elasticity decreased by 11% 25.

Conclusion

The qualities of concrete can be influenced by the use of reused concrete aggregate (RCA) in building in both positive and negative ways. The porosity of RCA's linked cement paste might lead to a lower relative density and higher water absorption when compared with natural aggregates. However, water absorption and sorptivity can be decreased in concrete of certain grades when recycled coarse aggregate is used in place of natural coarse aggregate. Professionals in the sector have a hurdle because of the diverse composition of RCA, which has different levels of water absorption and other qualities. Workability loss, however, can be reversed by modifying conventional water absorption techniques and perhaps using more super plasticizer. To comprehend the kinetics of water absorption when RCA comes into touch with cement paste, more study is required. Overall, even though using RCA can help with sustainable building practises by minimising waste, its properties must be carefully taken into account when creating concrete mixes.

Compared to natural aggregate (NA), recycled concrete aggregate (RCA) has various physical and mechanical characteristics, including a lower relative density, increased water absorption, and more porous cement paste because of the leftover connected mortar. The gradation of RCA and NA particles, however, is comparable, with correctly graded particles present in both cases. Recycled construction aggregate (RCA) particles are larger and more rounded than natural fine aggregate, and they have more fines broken off of them. The greater surface roughness of RCA might affect how easily concrete can be worked. These results underline how crucial it is to properly take into account the characteristics of RCA while creating concrete mixtures to get the best results.

The way recycled concrete aggregate (RCA) behaves in abrasion and crushing tests points to a possible weak point in the link between the aggregate and the adhering mortar. The crushing value and LA abrasion of recycled material, however, are still within acceptable bounds. Los Angeles coefficient of RCA can be lowered even when it is greater than that found in nature's aggregates by regulating the material's absorption of water and density. Overall, the investigations show that RCA can be used to replace natural coarse aggregate in concrete mixtures; however doing so may cause a reduction in compressive strength. This impact can be somewhat reduced with the application of super-plasticizers.

Up to 30% of coarse recycled concrete aggregate (RCA) was used in concrete mixes without affecting the concrete's strength, but as the RCA concentration rose, the strength of the concrete gradually decreased. Super plasticizers, however, have been shown to increase the mix's compactness and make up for the strength loss, according to a number of tests. The compressive strength of concrete tends to decrease when RCA content in the mixture rises; however, this effect is less pronounced when the proportion of water to cement is higher than 0.6. However, recycled aggregate can be used in high-strength concrete mixtures with good compressive strength.

Tensile splitting strength of concrete built with reused gravel reduces as the amount of recycled material in the mix rises. Using reused aggregate in place of natural aggregate can result in tensile splitting strengths that are on par with or even higher. Similar to this, as the proportion of recycled aggregate in the mix increases, concrete's flexural strength decreases. The average drop in flexural strength for mixes including recycled aggregate is roughly 9.2% when compared to the control mix with reused aggregate.

As the amount of used aggregate grew, its static modulus of elasticity dropped. Because residual mortar decreased the interfacial transition zone, the modulus of rupture for RCA concrete was somewhat lower than that of conventional concrete. The more ductile aggregate causes a lower modulus of elasticity than expected. Elasticity modulus dropped by 11%.

Acknowledgement

The greatest thanks are extended to our family and friends for their help and encouragement while we were drafting this paper.

Conflict of Interest

There are no conflicts of interest for the authors.

Funding Source

There is no funding or financial support for this research work.

References

- A Gupta, N Gupta, A Shukla, R Goyal, Kumar S. Utilization of recycled aggregate, plastic, glass waste and coconut shells in concrete - A review. In: IOP Conference Series: Materials Science and Engineering. Vol 804. ; 2020:1-8. doi:10.1088/1757-899X/804/1/012034

CrossRef - Katrina McNeil, Thomas H.-K. Kang. Recycled Concrete Aggregates: A Review. International Journal of Concrete Structures and Materials. doi:10.1007/s40069-013-0032-5

CrossRef - Shangliao Sun. Consumption volume of cement in India from financial year 2009 to 2019, with estimates until 2022. https://www.statista.com/. https://www.statista.com/statistics/269322/cement-consumption-in-india-since-2004/

- Sunita Narain. India manages to recover and recycle only about 1 per cent of its construction and demolition (C&D) waste, says new CSE analysis. Centre for Science and Environment. https://www.cseindia.org/india-manages-to-recover-and-recycle-only-about-1-per-cent-of-its-construction-and-demolition-10326#:~:text=New Delhi%2C August 25%2C 2020,just about 1 per cent. Published 2020.

- M. Quattrone, B. Cazacliu, S.C. Angulo, E. Hamard, A. Cothenet b. Measuring the water absorption of recycled aggregates, what is the best practice for concrete production? Constr Build Mater. 2016;123:690-703. doi:10.1016/j.conbuildmat.2016.07.019

CrossRef - Sherif Yehia, Akmal Abdelfatah. Examining the Variability of Recycled Concrete Aggregate Properties. Int Conf Civil, Archit Sustain Dev. Published online 2016:57-60. doi:10.15242/iicbe.dir1216403

CrossRef - CPCB. Annual Report 2010-21 on Implementation of Solid Waste Management Rules , 2016.; 2022. https://cpcb.nic.in/uploads/plasticwaste/Annual_Report_2019-20_PWM.pdf

- CPCB. Guidelines on Environmental Management of Construction & Demolition (c & d) Wastes. Vol 1.; 2017. https://cpcb.nic.in/openpdffile.php?id=TGF0ZXN0RmlsZS8xNTlfMTQ5NTQ0N jM5N19tZWRpYXBob3RvMTkyLnBkZg

- Sandy Patience, Anna Pamphilon, Dr Andrew Norton, Prof Callum Hill, Dr Peter Ruifrok, Mark Siddall, Cath Hassel, John Bullock. Aggregates for Concrete. Green Building Design. https://www.greenspec.co.uk/building-design/aggregates-for-concrete/

- Langer W. Sustainability of Aggregates in Construction. Second Edi. Elsevier Ltd.; 2016. doi:10.1016/b978-0-08-100370-1.00009-3

CrossRef - Rabin Tuladhar, Marshall A, Sivakugan N. Use of Recycled Concrete Aggregate for Pavement Construction. Elsevier Ltd.; 2020. doi:10.1016/B978-0-12-819055-5.00010-3

CrossRef - Satheesh. Properties of Aggregates and Its Importance! civilplanets. Published 2020. https://civilplanets.com/properties-of-aggregates/

- Alex Brewster, Scott brewster, Graeme jack, Caroline gray. Recycled aggregates: what you need to know. brewsterbros. https://www.brewsterbros.com/recycled-aggregates-what-you-need-to-know/

- Oikonomou ND. Recycled concrete aggregates. Cem Concr Compos. 2005;27(2):315-318. doi:10.1016/j.cemconcomp.2004.02.020

CrossRef - Natt Makul, Roman Fediuk, Mugahed Amran, Abdullah M. Zeyad, Gunasekaran Murali, Nikolai Vatin, Sergey Klyuev, Togay Ozbakkaloglu, Yuriy Vasilev. Use of recycled concrete aggregates in production of green cement-based concrete composites: A review. Crystals. 2021;11(3):1-35. doi:10.3390/cryst11030232

CrossRef - Tam VWY, Soomro M, Evangelista ACJ. A review of recycled aggregate in concrete applications (2000–2017). Constr Build Mater. 2018;172:272-292. doi:10.1016/j.conbuildmat.2018.03.240

CrossRef - González-Taboada, González-Fonteboa, F. Martínez-Abella, D. Carro-López. Study of recycled concrete aggregate quality and its relationship with recycled concrete compressive strength using database analysis. Mater Constr. 2016;66(323). doi:10.3989/mc.2016.06415

CrossRef - M. C. Limbachiya, T. Leelawat, R. K. Dhir. Use of recycled concrete aggregate in high-strength concrete. Mater Struct Constr. 2000;33(9):574-580. doi:10.1007/bf02480538

CrossRef - Chetna M. Vyas., I. N. Patel, D. R. Bhatt. Durability properties of concrete with partial replacement of natural aggregates by recycled coarse aggregates. Int J Civil,. 2013;3(2):125-134.

- Miquel Joseph, Zeger Sierens, Luc Boehme, Lucie Vandewalle. Water absorption variability of recycled concrete aggregates. Mag Concr Res. 2015;67(11):592-597. doi:10.1680/macr.14.00210

CrossRef - Lavado J, Bogas J, de Brito J, Hawreen A. Fresh properties of recycled aggregate concrete. Constr Build Mater. 2020;233:117322. doi:10.1016/j.conbuildmat.2019.117322

CrossRef - Marilda Barra Bizinotto, Flora Faleschini, Fernández CGJ, Diego Fernando Aponte Hernández. Effects of chemical admixtures on the rheology of fresh recycled aggregate concretes. Constr Build Mater. 2017;151:353-362. doi:10.1016/j.conbuildmat.2017.06.111

CrossRef - Shi Cong Kou, Chi Sun Poon, Dixon Chan. Influence of fly ash as cement replacement on chloride penetration and frost resistance of recycled concrete. J Mater Civ Eng. 2007;19(9):709-717. doi:10.4028/www.scientific.net/AMR.250-253.1031

CrossRef - Daniel Matias, Jorge de Brito, Alexandra Rosa, Diogo Pedro. Durability of Concrete with Recycled Coarse Aggregates: Influence of Superplasticizers. J Mater Civ Eng. 2014;26(7):1-5. doi:10.1061/(asce)mt.1943-5533.0000961

CrossRef - Bilal S. Hamad, Ali H. Dawi. Sustainable normal and high strength recycled aggregate concretes using crushed tested cylinders as coarse aggregates. Case Stud Constr Mater. 2017;7(August 2017):228-239. doi:10.1016/j.cscm.2017.08.006.

CrossRef