A Review: Design of Sewerage Scheme and Evaluation of Proposed Treatment Plant for Saatvik Vihar Phase-II, Indore, (M.P.)

1

Civil Engineering and Applied Mechanics Department,

Shri G. S. Institute of Technology and Science,

Indore,

Madhya Pradesh

India

Corresponding author Email: harshalvirde@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.17.3.2

Copy the following to cite this article:

Virde H, Dohare D. A Review: Design of Sewerage Scheme and Evaluation of Proposed Treatment Plant for Saatvik Vihar Phase-II, Indore, (M.P.).Curr World Environ 2022;17(3). DOI:http://dx.doi.org/10.12944/CWE.17.3.2

Copy the following to cite this URL:

Virde H, Dohare D. A Review: Design of Sewerage Scheme and Evaluation of Proposed Treatment Plant for Saatvik Vihar Phase-II, Indore, (M.P.).Curr World Environ 2022;17(3).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2022-08-28 |

|---|---|

| Accepted: | 2022-12-07 |

| Reviewed by: |

Eman H. Khader

Eman H. Khader

|

| Second Review by: |

Grigorios Kyriakopoulos

Grigorios Kyriakopoulos

|

| Final Approval by: | Dr. S. K. Dash |

Introduction

A sewage system is made up of numerous sewer lines that come together at one point to form a larger sewer line. Additionally, the massive sewer pipe comes to an end at the intersection of an even bigger sewer line. The outfall is where the main sewer line finally comes to an end. A sewage system can be thought of as a network of sewer lines that empty into another network of sewer lines after collecting discharges at their nodal points.1 There are different numbers of treatment units used for the treatment of wastewater the MBBR process is one. The MBBR method has been widely utilized to remove nitrogen and carbon from wastewater since it is well recognized and dependable.2 The biological oxygen demand (BOD) removal from municipal wastewater using an MBBR process typically results in SS concentrations in the 100–250 mg/L range 2 and even up to 500 mg/L. Since 2005, research on and commercialization of the removal of suspended solids (SS) by microscreens with woven media (either Disc filters or Drum filters) downstream of an MBBR have taken place. 3,4 The examination of the system's flow requires a lot of time and effort when designing a sewer network traditionally. The design of a sewer system is extremely challenging because so many crucial criteria/checks must be met at once. Due to the distinctive advantages, it offers, "SewerGEMS" software is very well-liked by everyone. Engineers may study and design sewer systems with SewerGEMS' very user-friendly built-in hydraulic tools. Additionally, it works with Geographic Information System (GIS) tools and AUTOCAD software. The software also delivers design parameters like the diameter of the pipeline and the invert levels of the manholes.5 Current research is focused on the design of MBBR unit and sewerage network by using “SewerGEMS” software.

Types of sewerage system

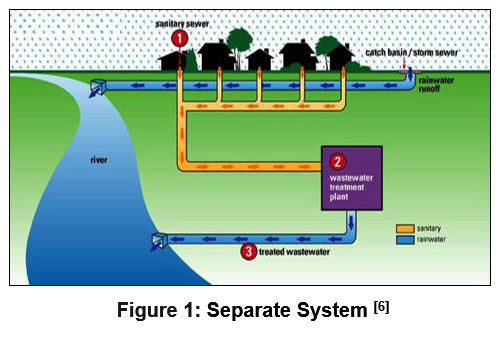

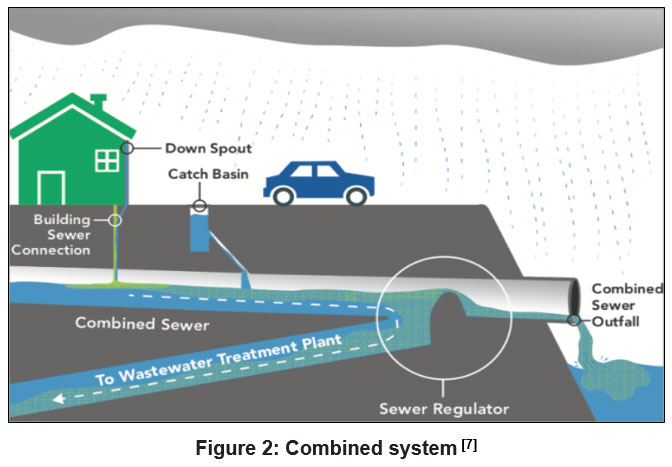

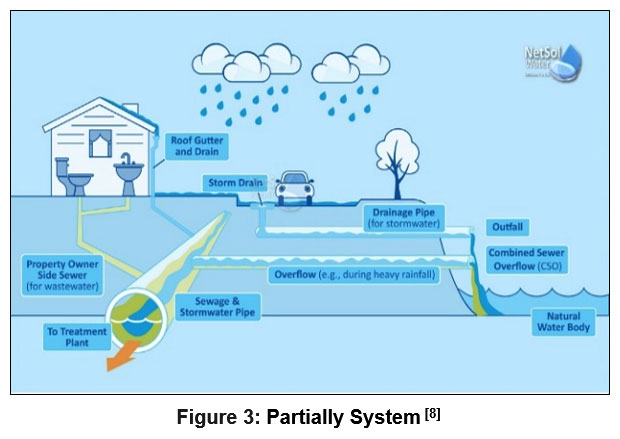

Sewerage or water conveyance systems are classified into three types:

- Separate System (Fig.-1).

- Combined System (Fig.-2).

- Partially System (Fig.-3).

Combined System

In these three systems, I am applying the combined system in this research work.

| Figure 1: Separate System 6

|

| Figure 2: Combined system 7

|

| Figure 3: Partially System 8

|

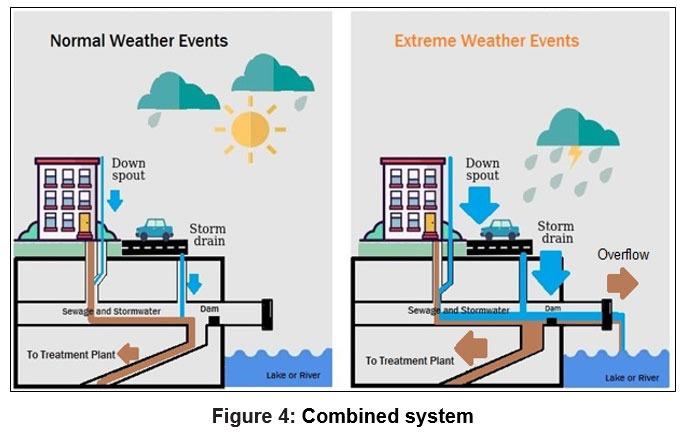

As shown in Fig.-4, the combined system has only one set of sewers for carrying domestic or sanitary sewage, industrial sewage, and stormwater (or rainwater). In this case, sewage and stormwater (or rainwater) are transported to a sewage treatment plant before being disposed of.

| Figure 4: Combined system

|

The combined system has the following advantages

- Since this system requires only one set of sewers and the maintenance costs are reduced, hence it may prove to be economical.

- The sewers being of a larger size the chances of their choking are less and also it is easy to clean them.

- The strength of the sewage is reduced by dilution due to stormwater (or rainwater). This helps to make the treatment process easier and more economical.

The combined system has the following disadvantages:

- The cost of construction will be high because large-size sewers are to be constructed at sufficient depth below the ground surface involving large excavation.

- Because of the large size of sewers, their handling and transportation will be difficult.

- Due to the inclusion of storm water (or rain water) treatment works of the larger size will be required and also the treatment units will be heavily loaded.

Sewergems

You may create the best urban sewer planning and overflow remedial study designs with OpenFlow SewerGEMS in a simple environment. By combining a range of wet-weather calibration techniques with built-in hydraulic and hydrology capabilities, you can design and manage sanitary or mixed conveyance sewer systems.[29]

Some Benefits of SewerGEMS

- Use one data source for the entire project.

- Result comprehension is improved.

- Simple scenario-based model management.

- Use current data to your advantage.

- Unlimited Flow Patterns can be entered and saved.[29]

Sewer Pipes

The pipes, also known as sewer pipes, are used to transport water or wastewater from a home or an outdoor industrial area. The sewer pipe needs special care because wastewater can cause it to break or corrode.22

Your home's sewer pipes perform a variety of tasks; there is only one pipe that can efficiently convey all of the waste water from inside your home to the outside. The sewer lines in your area serve to support the neighborhood's major thoroughfare.22

The sewer lines are located a few feet beneath the surface, leaving the residential and business owners with a good amount of clean space. The various sewer pipe kinds are utilized based on the local weather, and they are also repaired, replaced.22

Types of Sewer Pipes

- ABS and PVC Pipe

- Cast Iron Pipe

- Clay Pipe

- DWC Pipe

- RCC Pipe

In all these types of pipes, I am applying DWC and RCC pipes in this research work.

ABS and PVC pipes

One form of plastic pipe is PVC and ABS sewer pipe; PVC is a white plastic pipe and ABS is a black plastic pipe. Both the black and white plastic pipes feature a smooth interior portion for conveying solid trash 22

Additionally, it has a smooth external section that aids in preventing tree roots from becoming anchored. The PVC and ABS plastic pipe has a diameter of 4 inches and is readily accessible and extremely simple to utilize close to the construction site.

These days, the most practical and affordable pipes are those that are lightweight and easy to cut. 22

| Figure 5: PVC and ABS pipes 23

|

Cast iron Sewer pipes

This particular form of cast iron sewer pipe was typically utilized in older residences, but it is still used in older homes as a replacement pipe when the original cast iron pipes get damaged. When compared to other sewer pipes on the market, the cast-iron pipes have the advantage of being exceptionally sturdy. Cast iron pipes with a 4-inch diameter can resist up to two tones of pressure per linear foot, while ABS, PVC, and clay pipes are more likely to break. However, because of their weight, cast-iron pipes are difficult to utilize on construction sites and difficult to cut to the required size. When cutting cast iron pipe underground, you'll need a soil pipe cutter, which you may hire from a supply store for a minimal charge. An important benefit is that cast iron pipe is not combustible. Cast iron sewer pipes are being used in new residences more frequently due to the aforementioned rationale. 22

| Figure 6: Cast iron Sewer pipes 24

|

Clay Sewer pipes

Although there are still some instances today when clay sewer pipe is utilised in sewer construction, it is becoming less and less common. The clay sewer pipe is hefty in comparison to other sewer pipes, making it difficult to cut. The clay sewer pipe does, however, have a drawback in that it is not readily available on the market as most stores do not offer it. In terms of chemical resistance, clay sewer pipes have a significant advantage over plastic pipes. Extra drawback of clay sewer pipes is that they are susceptible to root damage because of how easily they may be penetrated by roots due to their larger surface area of pores. 22

| Figure 7: Clay Sewer pipes 25

|

DWC sewer pipes

Similar to regular HDPE pipes, Double Wall Corrugated (DWC) HDPE pipes have various external and internal surfaces that provide them more strength and stiffness. These have a very long lifespan because they are constructed of high-density polyethylene. These range in diameter from 75 mm to 1.0 m, have an internally smooth surface, and are externally corrugated. Because they are lightweight, these pipes can be utilized for cross drainage, non-pressure subterranean drainage, and rainwater collection. Since they require no maintenance, once installed, they will remain underground for many years. 26

| Figure 8: DWC Sewer pipes 27

|

RCC sewer pipes

Cement with reinforcement In the centrifugal spinning method used to create pipes, reinforcement cages that extend throughout the barrel and a mechanical mixer for mixing concrete are both used. Spirals or rings made of circles and straight pieces of mild steel wire make up the reinforcement cage for precast concrete pipes. Regarding the rcc pipe wall thickness, reinforcement cages are arranged symmetrically. Concrete is compacted in these precast concrete pipes by using a combination of vibration and centrifugal force to spin the pipes horizontally. 28

.jpg) | Figure 9: RCC Sewer pipes 28

|

Sewage Treatment Plants

A facility that treats sewage before releasing it into rivers, the sea, and other bodies of water.

Following are few STP process & System commonly used in India

- Activated Sludge Process (ASP)

- Sequencing Batch Reactor (SBR)

- Membrane Bio Reactor (MBR)

- Moving Bio Bed Reactor (MBBR)

- Fixed Bed Reactor (FBR)

- Electro Coagulation System (ECS)

- Sequential Bio Reactor (SBR)

- Rotating Bio Reactor (RBC)

Source: By Author

In all these types of treatment processes, I am applying MBBR process in this research work.

Moving Bio Bed Reactor (MBBR)

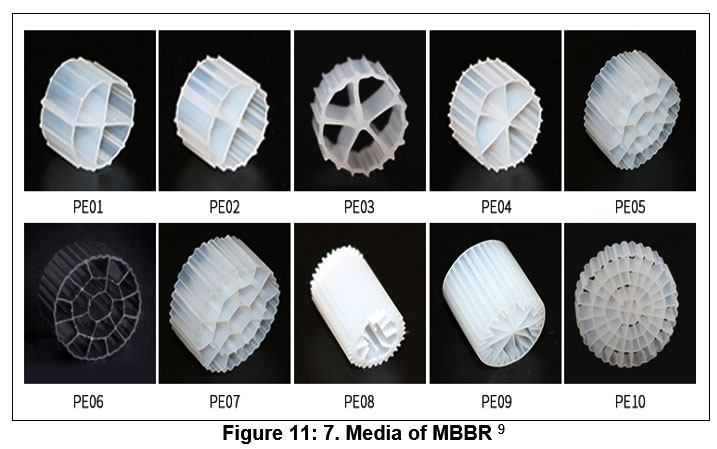

MBBR is an extremely successful biological treatments technology combines the standard process of activated sludge with biofilm media. The MBBR process utilizes High-Capacity Floating Micro Organism Biochips media in the aeration and anoxic tanks. These microbes consume organic stuff. The medium expands the surface area on which biological germs can attach and thrive. This larger surface area minimizes the wastewater treatment tanks' footprint. The MBBR treatment process can be aerobic or anaerobic, and it can handle massive amounts of water.9

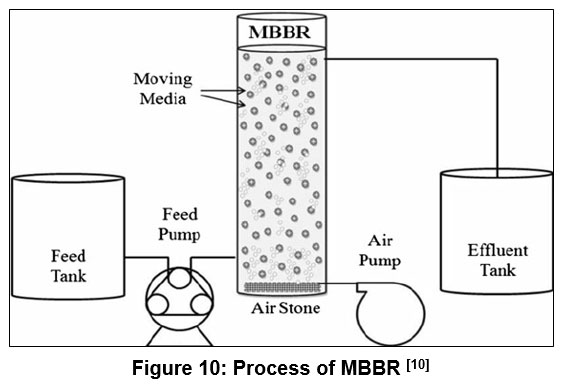

Working Process of MBBR

The MBBR process uses floating plastic carriers (media) within the aeration tank to increase the number of microorganisms available to treat wastewater. These microorganisms eat organic matter. The media enhances the surface area available to biological microorganisms in the aeration tanks for attachment and growth. The greater surface area minimizes the wastewater treatment tanks' footprint. The media is continuously agitated by bubbles from the aeration system that adds oxygen at the bottom of the first compartment of the aeration tank. Organic substance is consumed by the microorganisms. It outperforms conventional secondary treatment in terms of efficiency and value. Figure 5 depicts the MBBR operation. 9

| Figure 10: Process of MBBR 10

|

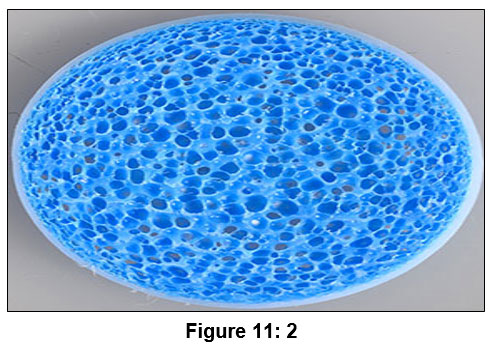

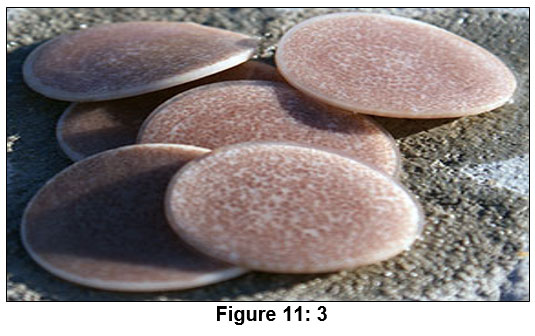

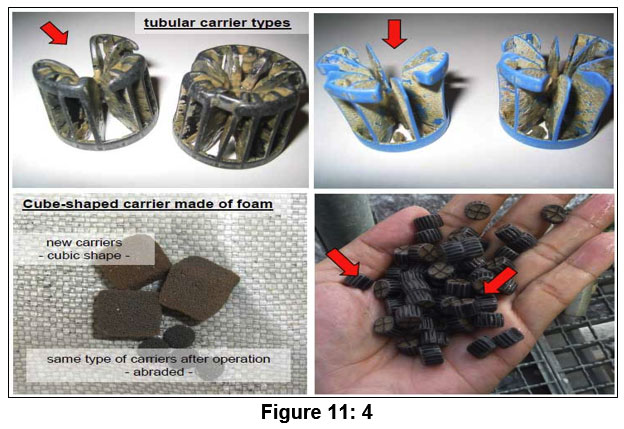

Media of MBBR Process

Fig.11 (I), (2), (3), (4), (5), (6) and (7) is showing some different types of media of the MBBR process:[9]

| Figure 11: 1

|

| Figure 11: 2

|

| Figure 11: 3

|

| Figure 11: 4

|

| Figure 11: 5

|

| Figure 11: 6

|

| Figure 11: 7. Media of MBBR 9

|

Factors Affecting MBBR System Performance

Following are some factors which affect the performance of MBBR system:[5]

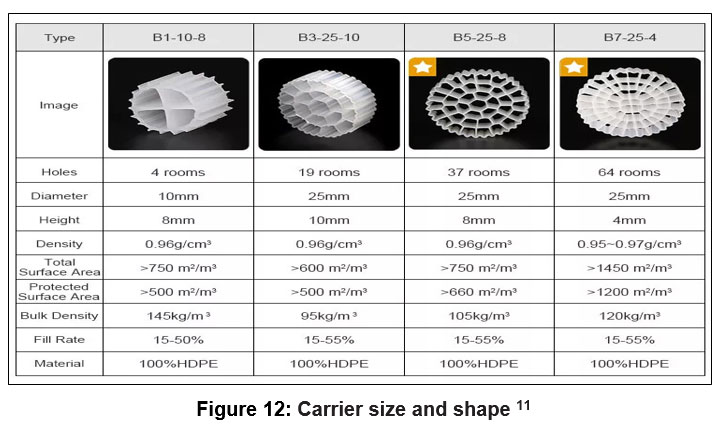

Carrier size and shape

To fit various uses, various designs of carriers with differing shapes and sizes have been designed. The researchers discovered that MBBR organic loading rates per carrier area (i.e., COD/m2•d) are critical for MBBR reactor treatment efficiency. The higher area has been demonstrated to boost the performance of those systems significantly. According to the findings of these same authors, the influence of the carrier area has no effect on the removal rates of carriers of varied shapes with the same surface area.11

| Figure 12: Carrier size and shape 11

|

Effect of percent fill

There was an associated degree of fill-fraction that might be larger, resulting in a reduction in the reactor's removal potency. Competition between suspended and attached biomass, as well as the relevance of suspended solids in the MBBR, are to blame. Because of its importance in the enzymatic hydrolysis process and bio-flocculation within the reactor, it was revealed that as the degree of fill-fraction grows, the suspended growth concentration drops, whereas low suspended biomass decreases the MBBR removal efficiency. A fill fraction of 35% was shown to be more effective at COD removal than a fill fraction of 66%.11

Effect of diffuse and mixing conditions

Other elements that have been claimed to influence performance include diffuse and mixed conditions within the reactor, as well as appropriate turbulence. The thickness of the biofilm on the carriers, for example, has an impact on the size of the portion of the biofilm that has access to substrates. The biofilm should be somewhat thin and equally dispersed over the carrier surface in this case. Turbulence inside the reactor, on the other hand, increases substrate transport to the biofilm, preventing the biofilm from becoming too thick due to shear pressures. Carrier mobility is critical in aerobic MBBR because media collision and attrition within the reactor produce biofilm separation from the media's outer surface. As a result, fins are added to the surface of the MBBR carrier media to limit biofilm loss and enhance biofilm growth.11

Impact of HRT

The efficiency of the MBBR can be increased by raising the HRT or by using numerous MBBR compartments. Chemical Oxygen Demand removal in MBBR systems is controlled by time required for hydraulic retention (HRT) and an HRT greater than 5 hrs. is recommended for increased productivity. Higher HRT, on the other hand, allows for sufficient contact time for OM biodegradation, and hence an extended contact time between support media and effluent improves waste material removal efficiency. This could be attributed to enough time for microorganisms to adhere to the surface of the carrier, resulting in the formation of an active biomass layer on the carrier's top. Due to the difference at operational conditions, the optimal HRT is completely different. For example, the optimal HRT is between 12 and 16.5 hours, with inferior performance when the hormone-replacement treatment is reduced to 9 hours.11

Impact of SALR

Because the MBBR's removal potency is determined by the biomass concentration in the reactor, the optimal removal efficiency was attained at the threshold loading rate. In this regard, Aygun et al [4] investigated the effects of increased organic input on COD elimination and sludge production in a MBBR. The experiment was carried out with a small-scale reactor with an operating volume of two (2) liters that was continuously filled with wastewater. Using different organic input rates of 6, 12, 24, 48, and 96 g COD/m2. d, a biofilm carrier (K1) was injected at 50% of the reactor's volume. According to the data, an increase in organic loading rate (from 6 to 96 g COD/m2. d) was accompanied by a drop in terms of organic removal capability (range from 95.1 percent to 94.9 percent, 89.3 percent to 68.7 percent, and respectively with the loading rates).11

Dissolved element of oxygen

For effective COD elimination, the Dissolved oxygen level in the apparatus must be retain at or above 2 milligram/Lit. The same authors discovered that lowering the DO from 2 to roughly 1 mg/factor in the system had a positive effect. Raising the DO from 2 to 6 mg/L, on the other hand, only boosted COD removal efficiency by 5.8%. Furthermore, because oxygen diffusion into the biofilm was limited, their results revealed that simultaneous nitrification and denitrification (SND) may be done in a one MBBR reactor with a HRT of six (6) hours. The highest N-removal potency (89.1 percent on average) was discovered when the Dissolved oxygen was held at 2 mg/L. Lower DO concentrations resulted in anoxic circumstances, restricting ammonia conversion to NO2 or NO3, whereas higher DO concentrations resulted in no anoxic conditions, prohibiting denitrification inside the biofilm's deeper layers. L, the elimination efficiency of COD dropped by 13%, demonstrating that DO is a limiting factor.11

Advantages of MBBR method

Some of the advantages of MBBR system

- Small and compact units

- Enhanced capacity for treatment

- Removal of all solids

- Improved settling properties

- Higher suspended biomass operation

- High concentrations result in lengthy sludge retention times.

- Greater process stability

- Very little head loss

- No filter channeling

- There is no need for backwashing on a regular basis.

- Less sludge generation and no sludge bulking problems.[11]

MBBR wastewater treatment disadvantages

Manual monitoring

One downside of MBBR systems is that they require manual monitoring. This is true of biological water treatment methods in general. Unlike other forms of water treatment, which can employ sensors to monitor the system's progress, a biological system, such as MBBR tank, requires an operator to take samples and test them on a regular basis to guarantee the bacteria on the carriers are still alive and well.20

Skilled specialists

Another drawback of biological systems is that operators must be experts in the field of biological water treatment. This is required so that the media can be adequately analyzed to confirm that it is still digesting the waste in the tank. Of course, as we've seen, operating the tank is a straightforward, mostly hands-off process. 20

Insects

Another disadvantage of dealing with biofilms is that some insects, such as sewage flies, mosquitoes, and red worms, will be drawn to it. This could result in a portion of the biofilm on the carriers being consumed by insects, jeopardizing the system's functionality. Tanks built to keep these insects out can help treatment plants avoid this problem. 20

Escaping carriers

Despite the strainers in place to keep the carriers in, some customers have noted that the carriers can wash out of the system over time, even when there are no insects around. This could also be the result of a design defect in the tank itself. 20

Proposed Methodology

- Software Work.

- Cost Comparison of Conduits or pipes.

- Cost Comparison of Treatment Units.

- Design of MBBR Unit.

For Software Work:

- Conformation of site location.

- Preparation of AutoCAD layout.

- Ground level survey of site.

- Population forecasting.

- Addition of manholes in software.

- Addition of conduit or pipes in SewerGEMS software.

- Addition of Ground level and Invert Level software.

- Addition of demand in SewerGEMS software.

- Analysis/Compute the network in SewerGEMS and preparation of excel sheet with the help flex table of final results.

Cost Comparison of Conduits or pipes

- First Comparison:

- Complete the sewerage line network.

- Use of DWC (Double Wall Corrugated) conduits.

- Comparison of final cost from MPSOR (Madhya Pradesh Schedule of Rates).

- Second Comparison:

- Complete the sewerage line network.

- Use of RCC (Reinforced Cement Concrete) conduits.

- Comparison of final cost from MPSOR (Madhya Pradesh Schedule of Rates).

- Third Comparison:

- Complete the sewerage line network.

- Use of both DWC & RCC conduits.

- Comparison of final cost from MPSOR (Madhya Pradesh Schedule of Rates)

Cost Comparison of Treatment Units:

- For MBBR, SBR & MBR treatment units

- Design of complete sewerage network.

- Total capacity of sewage generated.

- Cost comparison from MPSOR (Madhya Pradesh Schedule of Rates).

Source: By Author

Design of MBBR Unit.

A number of crucial factors go into the process design of the MBBR system, including the site-specific treatment objectives, the availability of suitable pre-treatment facilities, the quantity of bio-carriers and their physical characteristics, the aeration facilities, which include air flow rate, the physical dimensions of the aeration tank, reactor porosity, etc. Using an appropriate process design method, it is also possible to determine the best HRT and SRT (c) for a target effluent concentration under a known influent concentration. For municipal and industrial wastewater treatment using an ASP or trickling filter, there are a number of standard process design techniques. However, very little research has been done to date on the creation of an appropriate process design approach for MBBR systems. Most MBBR systems currently solely rely on empirical models and various data obtained from prior experience for process design. Although numerous academics have developed various mathematical models for MBBR, including as physical models and statistical models, these models are shown to be incompatible with the process design. This is the case because using the currently available models is difficult and the solution process entails a number of difficult procedures. Therefore, it is imperative to create a proper design methodology for more accurately anticipating MBBR performance. In order to address this issue, a straightforward process design technique is suggested below in accordance. Competition between attached biomass and suspended growth for a single electron donor molecule under moving conditions has been taken into account when developing the process design for MBBR. The fundamental equations for the process design of MBBR have been derived using the straightforward Monod kinetic expression for substrate consumption and biomass development simultaneously combined with Fick's second rule of molecular diffusion. The mass balance equation has also taken detachment of biomass from biofilm due to hydraulic shear loss and loss due to collision between moving particles into account.For defining the various components in the process design of MBBR, the values of various bio-kinetic coefficients, such as k, Ks, and Y, as well as certain bio-film related properties, such as bs, bt, and bd, are either determined experimentally or derived from standard literatures. The following factors are crucial to process design: (1) aeration tank capacity; (2) aeration equipment; (3) reactor porosity; and (4) ideal hydraulic and solid retention times. The best concentration of suspended biomass (X), according to a variety of literature and practice manuals, is typically between 2500 and 3000 mg/L for good biomass settleability in the secondary clarifier. In the event of recirculation, the biomass concentration in waste sludge is designated as Xr, which ranges between 10,000 and 12,00 mg/L. 21

- Determination of Reactor Volume (V). 21

- Determination of specific surface area (a). 21

- Determination of react or porosity (p). 21

- Oxygen requirements.21

Literature Review

Y.W. Zhao (February 2008) A case study of the Nansha District in Guangzhou, China as a case study, was presented. This study was based on GIS technology, which presented an application of eco-suitability evaluation to resolve the issue of optimum locations of waste disposal plants and discharges. According to the learning, there are 212 km2 of land suitable for STP, 87 km2 of land appropriate for sewage discharge, and 6 km2 of land unsuitable for sewage outfalls. The methodology included three steps: data collection, spatial investigation of GIS, and integrated eco-friendliness assessment. The results of the research show the areas that are suitable, generally suitable, and unsuitable locations of water, land & riparian area.12

Murugesh katti et al. (July 2015) Presented a study on modeling design of Network of Sanitary Sewers by using SewerGEMS V8i application software. The SewerGEMS V8i software accomplished the project with high efficiency & low costs, in a short time. This software is the first software which gives the sanitary & combines sewer modelling solution & it is fully dynamic. Detailing part of the software consists the micro station mode, Arc GIS mode, AutoCAD mode. Preparation of the schematic & scaled model of sewage network is more efficient. Layout of sewer network is easy to prepare. This software run in both stand-alone & micro station mode. The conclusion of this study was that, the software takes less time create drawing, automatically update data for layout, it is easy & simple for designing large sanitary sewer network.13

Lukasz Kopec et al. (2016) Carried out a research work on Moving Bed Biofilms Reactor (MBBR). For this research they consider prototype MBBR, and a system of technology comprised of a two trickling filters and septic tank (Bioclere trickling filters). The MBBR devices are deployed at the conclusion of the technical system for the post-denitrification process. The study's major goal is to investigate the rate efficiency of the denitrification process, which is affected by the concentration of chemical oxygen needs as well as suspended biomass concentrations and attached biomass on the moving bed surfaces of the EvU Perl. The moving bed EvU The moving bed was discovered to be not the primary medium of biomass, with just 6 percent of the total biomass adhering to the moving bed outer. The MBBR device demonstrates the ability to achieve high-rate denitrification at organic carbon concentrations greater than 300mg o2/dm3, with a maximum denitrification rate of 0.79 gn-NO3/gDM.d. As a result, the device is simple to use..14

Rajat Palya, Dr. V.K. Sethi (February 2018) Worked on the design of a sewage treatment system for the Kohefiza neighborhood in Bhopal, M.P. The waste water generated by houses is disposed of into bodies of water without treatment, causing water pollution and environmental effects. The main purpose of this research was to reduce the sewage contents from the sewage & produce a treated solid waste & effluent for the reuse back or discharged into the environment or into the natural water course. For design of the sewage treatment unit and the design treatment period taken between 25 to 30 years. The conclusion obtained from this study was that the treatment plant designed according to the Indian codal provision for next 30 years was perfect. Also, the plant consists all the components of sewage treatment plant.5

Devendra Pandey et al. (March 2018) I worked on the integrated drainage system design of Gondia, Maharashtra, India, utilizing GIS techniques. In the present study Gajanan colony is taken as research, which is located in Gondia city at the longitudes 80°11’34.2.28” E & 80°11’49.19” E & latitudes 21°28’21.15” N & 21°28’39.39” N. In the past time Gondia city has conventional and open drainage system. Thus, the goal of the study was to create an efficient drainage system for the city's resident. The researchers design the system for the both storm weather flow & Dry weather flow. To execute the plan, topography of the city obtained from the contour plan & merged with the location of roads & streets. The GIS technique has been used for the layout & alignment of the city for sewer design. The rational method of sewage design is adopted for determination of storm water discharge. The researcher adopted both the conventional drainage methods and modern Sustainable Drainage System (SuDS) for waste water & storm water discharge, during both dry monsoon and dry season conditions. The study concludes the use of the remote sensing for city and also found another option of development of ponds, basins, filler strips, swales near the pangoli river bank.15

Hinal sopariya et al. (April 2018) Carryout research for analysis & design of sewer network with the help of SewerGEMS V8i. The SewerGEMS software consist hydrology and hydraulic tools to analyze design of sewer network system. This software very easy to use and popular because it provides unique benefits to engineers. This research mainly aimed to design a sewer network with the use of sewer SewerGEMS. This software provides the four platform namely windows stand alone, ArcGIS, Micro station and AutoCAD also offers users to input & save number of patterns. The SewerGEMS gives facility to modelling of Hydrogen Sulphide formation. The methodology of SewerGEMS consists three different methods of population forecasting such as, There are three types of increase methods: arithmetic, incremental, and geometric then average of three methods gives the final population. The road network layout of town drawn into AutoCAD, then the features of ground elevation generated in GIS platform and then imported into SewerGEMS The conclusion comes out from the observation was that SewerGEMS provide facilities to drawn layout and longitudinal section easily, satisfying condition for maximum & minimum velocity and very efficient for large sewer network and easy to use.1

Madhuri R. Patil, S.M. Bhosale (January 2020) Carried out a case study of the Hatkanagle village, which is a Taluka in Kolhapur District of Maharashtra state, India. Hatkanagle, village has no proper system of dirty fluid fetched. The dirty fluid is directly indoctrinated on open grounds on near houses and also gutters used for disposal. Gram panchayat of these gaon, has a development plan, to avoid the pollution due to openly persuade sludge, the worked on the declination to provide underground closed channel lines. The mapping of closed channel line networks done by using GIS software & also by the GPS. This village is situated on 16°44’38” N Latitude & 74°26’46” E Longitude & has a population of 13,679. Survey of the existing network shows that, total 1.06 MLD generated sewage is directly discharge into nallas. The parameters for the objective of the study were, collection of data, Location for Sewage Treatment Plant, Design of Underground sewage collection system, Mapping by GIS. The main objective of the project was to increase access to improve & sustainable domestic sewage disposal system by GIS & GPS to provide healthy & clean atmosphere to village.17

Ajay Livingston et al. (2020) Presented a work on a design of Sewer Network for the Kophard Village, Virar -Vasai. The main of this study was designing sewer system for a particular portion of the kophard village. For this work the GIS has been used for mapping work of sewer network & design of a sewer line. GIS is the most powerful & efficient tool on the wastewater industry. Data collection from the municipal council of village for designing of domestic sewage & design of sewage system were the objective of the study. In this study, Arithmetical Increase Method adopted for the population forecasting. The various design parameters such as Water supply rate, slope, peak factor, velocity, and pipe size are all factors to consider. This work has made use of depth of cover and manholes. The survey of the desired area was done by the total station for placing the sewer system. The study concluded the population growth rate was 0.23 from year 1988 to 2018, proper planning of underground sewage system will solve the problem of blocking of pipes.17

P. Kangsepp et al. (2020) Carried out a research work for a small-scale municipal WWTP of 5700 population equivalents. For this research, the small-scale WWTP upgraded to 12000 population equivalents to meet the future treatment needs. In this process they combined the MBBR with the coagulation, flocculation and disc filter. The conclusion of this robust and compact treatment system shows that, it is very good reduction in turbidity, COD was decreased from 290 to 10 mg/L, ammonium was reduced from 19 to 0.04 mg/L, and TP was reduced from 4.5 to 0.3 mg/L. Furthermore, full-scale effluent needs can be met by combining MBBR, coagulation, flocculation, and disc filtering in the absence of a main clarifier the MBBR.18

Natish Sayyed et al. (March 2021) Have research on the planning and designing of a sewage line system for the Mahurzari village, Nagpur, Maharashtra. The study of present work shows that the Mahurzari village generation in excessive sewage production in future, due to waste water discharge from the residential, commercial, industrial buildings etc. The project of sewage treatment plant is designed for the next 30 to 40 years (2021-2061) of future. The researchers consider all the waste water sources, storm sewage for planning & designing of treatment plant. The main objective of work to produce an environmentally safe solid waste and fluid waste, which is suitable for reuse or disposal. The data collected from gram panchayat records & survey of village. The design of Sewage system done manually, then compared with the software. The waste water is treated through various process like removal of chemical, physical & biological contaminates, which present in it. This research concludes the construction of sewage treatment plant is quite necessary in village from future aspect, for he approximate 3,00,000 population.19

Conclusion

Any new society must have a functioning waste water treatment facility and sewage system because these amenities are advantageous to the populace. With the help of the SewerGEMS software, we can rapidly and easily design a sewerage network as well as modify the design of a network as it is being created. Given how scarce fresh water supplies are at the time, it is imperative to implement waste water treatment technology. The MBBR technology has lately witnessed an upsurge in use across a variety of countries in terms of wastewater treatment under various loads and operating situations. When compared to other sewage treatment techniques, MBBR is an effective way to treat waste water. Despite having low maintenance costs, it has a high initial investment. Its hydraulic retention time is rather brief. Additionally, setting it up takes significantly less space.

Acknowledgement

We would like to thank the team of the Google scholar and other article web links.

Conflict of Interest

The authors do not have any conflict of interest.

Funding Sources

The author(s) have received no financial support.

References

- Sopariya H., Patel R.L., and Pathak Y.P. Analysis and design of sewer network using SewerGEMS. Int. J. of Crea. Res. Thoughts. 2018;06(02):1538-1543.

- Ødegaard H., Rusten B. and Westrum T. A new moving bed bioreactor – applications and results. Water Sci. and Tech. 1994;29(10–11):157–165.

- Wilén B.-M., Johansen A. and Mattsson A. Assessment of sludge particle removal from wastewater by disc filtration. Water Practice and Technology. 2012;7(2).

- Persson E., Ljunggren M., Jansen C.L., J., Strube R. and Jonsson L. Disc filtration for separation of flocs from a moving bed biofilm reactor. Water Sci. and Tech. 2006;53(12):139–147.

- Palya R., and Sethi Dr., V.K. Design of sewage treatment plant for a locality in bhopal to recycle the liquid waste. Int. J. of Engg. Sci. and Res. Tech. 2018; 7(2):193-199.

- Rohit Gurjar. Separate System.

- https://medium.com/@rohitgurjar009/sewerage-system-a8f554e5c8d0.2018.

- Combined Sewer Overflow. NYC.gov.https://www.nyc.gov/site/dep/water/combined-sewer-overflows.page.

- Partially System. Netsol Water Pvt. Ltd. https://www.netsolwater.com/combined,-separate-and-partially-separate-sewerage-systems.php?blog=2115.

- Moving Bed Biofilm Reactor (MBBR). Ecologix Environmental Systems. https://www.ecologixsystems.com/system-mbbr.

- Seyyed Ali Akbar Nakhli. Process of MBBR. Researchgate. https://www.researchgate.net/figure/Flow-diagram-of-MBBR-experimental-setup_fig1_260684513.

- Kawan A.J., Hasan A.H., Suja F., Jaafar B.O., and Rahman A.R. A review on Sewage Treatment and Polishing Using Moving Bed Bioreactor (MBBR). J. of Engg. Sci. and Tech. 2016:11:1098-1120.

- Zhao Y.W., Qin Y., Chen B., Zhao X., Y. Li, Yin X.A., and Chen G.Q. GIS-based optimization for the locations of sewage treatment plants and sewage outfalls-A case study of Nansha district in Guangzhou city China. Comm. in Nonlinear Sci. and Num. Sim. (ScienceDirect). 2007;14:1746-1757.

- Katti M., B.M. K., and B. M.K. Design of sanitary sewer network using Sewer GEMS V8i software. Int. J. of Sci. Tech. and Engg. 2015;02(01):254-258.

- Kopec L., Drewnowski J., and Kopec A. The application of moving bed biofilm reactor to denitrification process after trickling filters. Water Sci. & Tech. 2016;14(12):2909-2915.

- Pandey D., Katpatal Y., Kundal B., P P., and Chandrayan, V R. Integrated drainage design using GIS technique of gondia city Maharashtra India. Int. J. of Recent Sci. Res. 2018;09(03):24811-24816.

- Patil M. R., and Bhosale S.M. Design and mapping of underground sewerage network using GIS & GPS-A case study of Hatkanangle village. Int. Res. J. of Engg. and Tech. 2020;07(01):1385-1387.

- Livingston A., Patel H., Rumao G., Vaghadia G., and Dr. Godboley B.J. Design of sewer network for Kophrad village virar-vasai. Int. J. of Innov. in Engg. and Sci. 2020;05(06):15-18.

- Kangsepp P., Sjolin M., Mutlu A.G., Teil B., and Pellicer-Nacher C. First full-scale combined MBBR, coagulation, flocculation, disc filter plant with phosphorus removal in France, Water Practice & Tech. 2020;15(1):19-26.

- Sayyad N., Giradkar A., Dhore C.D., Dhore M.D., Patel H.S., Sondawale A.S., Rapanji R.D., and Ram A.S. Purpose of planning for sewage line system for Mahurazari village. Int. J. of Innov. Res. in Sci., Engg. and Tech. 2021;10(3):2468-2471.

- MBBR wastewater treatment method disadvantages. Netsol Water Pvt. Ltd.

- https://www.netsolwater.com/pros-and-cons-of-mbbr-technology.php?blog=1984

- Goswami S., Mazumder D. Moving Bed Bioreactor (MBBR) for wastewater treatment — A Review. J. Indian Chem. Soc. 2019;96:215-229.

- Sewer Pipes. Civil jungle. https://civiljungle.com/types-of-sewer-pipes.

- PVC and ABS pipes. Indiamart.

- https://www.indiamart.com/proddetail/pvc-pipes-19661865673.

- Cast iron Sewer pipes. Indiamart.

- https://dir.indiamart.com/search.mp?ss=cast+iron+pipes&prdsrc=1&mcatid=2047&catid=490&stype=attr.

- Clay Sewer Pipe.https://mbat.co.nz.

- DWC pipes.

- https://rdso.indianrailways.gov.in/works/uploads/File/Double%20wall%20corrugated%20(DWC)%20HDPE%20Pipe(1).pdf

- DWC Pipes. Veekay Plast.

- https://veekayplast.in/dwc-pipes-sewerage.

- RCC Sewer Pipes. BRCH Concrete Industries.

- https://www.brhcpipes.com/blog/What-are-RCC-Pipes/#:~:text=Reinforced%20concrete%20Pipes%20are%20manufactured,straights%20of%20mild%20steel%20wire.

- SewerGEMS. Bentley System, Incorporated. https://www.bentley.com/software/openflows-sewergems/