Optimized Hybrid Upflow Anaerobic Sludge Blanket with Post Treatment Processes for Wastewater

1

Department of Environmental Engineering,

L.D. College of Engineering,

Ahmedabad,

Gujarat,

India

2

Department of Civil Engineering,

L.D. College of Engineering,

Ahmedabad,

Gujarat,

India

Corresponding author Email: bina.patel@ldce.ac.in

DOI: http://dx.doi.org/10.12944/CWE.16.1.29

Copy the following to cite this article:

Patel B. B, Gundaliya P. J, Amin D. D. Optimized Hybrid Upflow Anaerobic Sludge Blanket with Post Treatment Processes for Wastewater. Curr World Environ 2021;16(1). DOI:http://dx.doi.org/10.12944/CWE.16.1.29

Copy the following to cite this URL:

Patel B. B, Gundaliya P. J, Amin D. D. Optimized Hybrid Upflow Anaerobic Sludge Blanket with Post Treatment Processes for Wastewater. Curr World Environ 2021;16(1). Available From : https://bit.ly/3bb61FR

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 07-10-2020 |

|---|---|

| Accepted: | 2021-02-02 |

| Reviewed by: |

Md Nuralam Hossain

Md Nuralam Hossain

|

| Second Review by: |

Grigorios Kyriakopoulos

Grigorios Kyriakopoulos

|

| Final Approval by: | Dr. Gopal Krishan |

Introduction

Environmental pollution is a present global issue waiting to be addressed. It is a subject that troubles us physically, economically and disrupts the day to day functioning of our lives1,2. Wastewateris usually classified as municipal wastewater (domestic wastewater or sewage) and industrial wastewater, which is inevitable in a country like India3,4. Efficient treatment of the wastewater is a big challenge to the corresponding authorities. India faces severe problems of collection and disposal of wastewaterbecause of rapid industrialization andurbanization5. To cope up with unprecedented water stress, the wastewater treatment processes are being looked upon6,7.

There are usually three types of wastewater treatment methods, physical which includes screening, floatation and sedimentation, chemical which comprises of chemical coagulation, chemical oxidation, adsorption, deionization, electrodialysisis and biological treatments8. Physical processes are quite inefficient and can only be considered as a primary treatment, whilst the chemical processes remain to be well above the economic capacities9. Due to these drawbacks, biological treatments are being increasingly preferred in wastewater treatment. Two types of biological wastewater treatments can be done i.e.aerobic treatment and anaerobic treatment8,9

Aerobic Treatment of Wastewater

In aerobic systems, wastewater is introduced into a reactor where an aerobic bacterial culture either in suspension or attached form convert the wastes into simple end products. In contrast, within anaerobic schemes, wastewater purified by the anaerobic attached/suspended biomass and biogas and small amount of sludge is produced10,11.

Various aerobic treatment processes like activated sludge process, bio tower, rotating biological contractor, trickling filter, fluidized bed reactors, aerated lagoons, sequencing batch reactor and oxidation ponds etc. are used for wastewater treatment have disadvantages which includes increased energy requirements in conjunction with huge quantity of sludge production which successively requires storage, treatment and disposal facilities12.Aerobic process includes the primary sedimentation tank, aeration systems, secondary sedimentation tank, sludge thickening or dewatering and sludge drying beds which are barely preferred. Aerobic digestion also achievethe poor degradation of complex compounds11.

Anaerobic Treatment of Wastewater

In anaerobic process, anaerobic bacteria break down the biodegradable organic matter present within the wastewater through the four steps activities i.e. hydrolysis, acidogenesis, acetogenesis&methanogenesis and biogas is generated5,8,13,14. A considerable part of organic carbon is converted to biogas while a very little portion is converted to sludge.

Anaerobic digestion treatment has been continuously developed and applied to wastewater treatment systems since a really long time now. These are duly preferred as they provide a wide range of advantages as compared to the aerobic digestion processes such as higher loading rates followed by low operation cost, higher biogas production, low discharge levies along with shorter pay-back times15.

Goal of this paper is to provide a holistic review on the present state of research on hybridized UASB specific biological treatments for both industrial and municipal wastewaters. A technically wholesome study has been discussed in this paper on the various hybrid UASB lab reactors under experimentation across the globe. This study further aims to summarize the optimum treatment initialization process along with respective parameter values for enhancing the treatment efficiencies. The practices of inert media and seeding optimizations have been given prime importance as major deciding factors of efficient treatment along with varied operational parameters16–22.

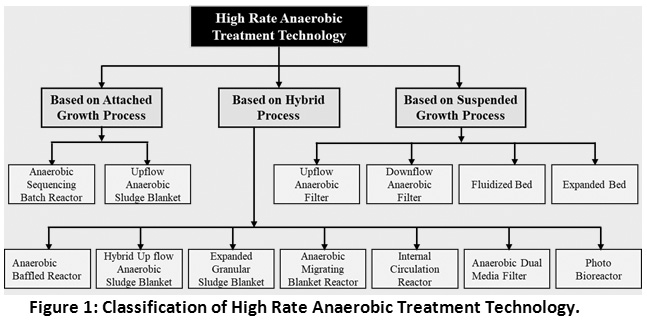

High Rate Anaerobic Treatment Technology

High rate anaerobic reactor can work more efficiently because the active biomass is retained, which is the key concept here. The Solids Retention Time and biomass concentration is increased without the exclusive increase of Hydraulic Retention Time. One advantage of high rate anaerobic reactor is that it can withstand against high Organic Loading Rate as biomass stays for a longer period.In many instances, combination of more than one mechanism is included in a bioreactor. Based on these combinations high rate anaerobic treatment technology has been classified as shown in figure 1.

| Figure 1: Classification of High Rate Anaerobic Treatment Technology. Click here to view Figure |

UpflowAnaerobic Sludge Blanket, anaerobic contact process, anaerobic filters, anaerobic packed bed reactor, anaerobic fluidized bed reactor, anaerobic migrating bed reactor, expanded granular sludge bed, etc are examples of anaerobic treatment technologies. UASB reactors have provided efficient outcomes among a wide range of anaerobic wastewater treatment technologies23.

An UASB reactor can be described as a tank or vessel, in which the wastewater is introduced from bottom by the means of an inflow distributer and it further flows upward through a sludge bed consisting of various bacteria in granular form. These bacteria are granulated by the means of an auto immobilization process which implies that the formation of sludge granular particles is brought about without the interference of any inert particles24. This particular characteristic of the UASB is widely exploited for enhances results as compared to other anaerobic treatments.

The influent wastewater is the degraded result of continuous anaerobic digestion process by various groups of bacteria. The factors affecting the organic matter degradation is the presence of active biomass along with the influent flow rate.At the end of anaerobic organic matterdegradation biogas is produced, which consists of methane and carbon dioxide. The co benefit of this process is the significant reduction of sludge volume which can be duly considered from a pollution control view1,24.

UASB reactors have been effectively used in tropical countriesand now-a-days are also being used in subtropical and temperate regions. It can be used for low strength wastewater (domestic wastewater)as well as high strength industrial wastewatertreatment1,2,25–28. UASB process has concludedto be most convenient and reliable. UASBs have been applied to treatvariousindustrial wastewaterlike pulp and paper, dairy, sugar, pharmaceutical, chemical,textile, soft drinks, fish processing, noodle processing, food processing, coffee processing, bean balancing, slaughterhouse andyeast production1. In 1970s , it was most feasible in countries like India, Colombia and Brazil where financial budgetaryresources are really scare7,11. Different towns in Brazil have reveal an interest in adopting anaerobic treatment as a decentralized treatment system for poor and sub-urban districts because it is often operative on a very small also as large scale. Therefore, it's a sustainable alternative for wastewater treatment for a newly developing areas of a town or city7. Currently about 60% of the thousands of anaerobic industrial wastewater treatments are extensively depended on the UASB technology25.

Hybrid Upflow Anaerobic Sludge Blanket

Globally, numerous researchers haves suggested anaerobic systemfor municipal and industrial wastewatertreatment in tropical and subtropical regions29.UASB is one such treatment process which is known to produce a significantly low volume of sludge along with higher biogas production. There are several ways to improve the efficiency of a UASB reactor, which includes operating it at a low temperature in order enhance the available surface area for the purpose of biomass attachment just above the sludge blanket in the reactor25.

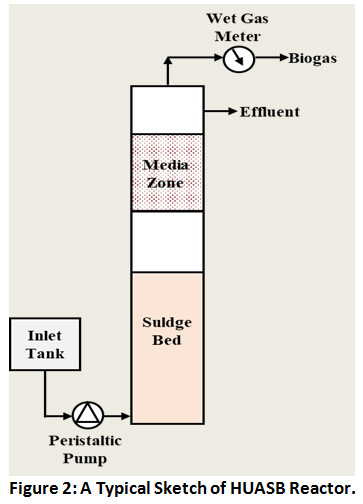

HUASB technology was developed by SR Guiot and L Van den Berg in 198417,30–33. It is an amalgamation of UASB and anaerobic filter15,34. Flocculent and granular sludge formation has developed in the lower portion of the reactor, which act as a UASB whereas the upper portion consists of a fixed film reactor with some inert media used. Various researchers have successfully used the HUASB reactor for the treatment of domestic wastewater33,35, Fruit Juice Factory wastewater36, Pulp & Paper Mill wastewater15, Alkali Treatment of Rice Straw wastewater37, Poultry Slaughter House wastewater38, Wood Fibrewastewater34, Coal wastewater (containing toxic phenolics30, Leather Effluent39, Pharmaceutical wastewater18,40,41, Distillery Spent Wash19, Olive Mill Effluent42, Sago wastewater31, Dairy Industry wastewater43,44. This type of reactor is called by various names like Hybrid Upflow Anaerobic Sludge Blanket reactor, Anaerobic Hybrid Reactor, Up-flow Bed Filter, Sludge Bed Filter or just hybrid anaerobic reactor15.

HUASB is an upgraded kind of the UASB reactorwith inert media used like sand, rock, slag, gravel, and a variety of synthetic and plastic materials for attached growth processes. Ithas the advantages of UASB and fixed film reactors, which offersthe large variations in loading rates, as most of the anaerobic bacteria adhere firmly to the inert media used (20–40% of the reactor volume) even at a very high up flow velocity of wastewater, the developed biofilm or suspended solids (SS) is not washed away. Therefore, Efficiency of the reactor can be improved. Figure 2 is an example of sample HUASB reactor.

Performance of UASB can be enhanced by keeping the inert media to the upper portion 20 to 40% of the reactor capacity and this kind of reactor has been reported to be stable for soluble or partially soluble wastewater treatment. It may offer better surface area for biomass growth & consequent higher efficiency than that of an anaerobic reactor. Hybrid reactors have been studied since so long,due to the possibilities of introducing various inert media and efficiency enhancement through operational parameter optimization UASB can be used to treat a wide spectrum of wastewater.

| Figure 2: A Typical Sketch of HUASB Reactor. Click here to view Figure |

Apart from main advantages of high rate anaerobic reactors,HUASB has the followingbenefits15,38:

- Biomass generally builds up in the unpacked zone

- The packed zone in the reactor helps to retain the non-attached sludge bed and acts as a polishing area to enhance the functioning of the process.

- The cost of packing media is quite low.

- It can be used as an alternative for the UASB reactor where granule formation is hindered and hence stable operation is difficult.

The purpose of this review paper is to evaluatethe hybrid HUASBrector that various researchers have attempted and alsodiscussesthe various post treatment options to raise the capability of the entire process. So that detailed understanding and comprehensive knowledge on HUASB treatment technologies could be attained and that would be helpful for the development of an optimized HUASB treatment technology in a case study plant design.

Characteristics of Wastewater and Subsequent HUASB Treatment

Domestic Wastewater

Domestic wastewater / Sewage contains suspended, colloidal and dissolved contaminants, which may be organic and inorganic. Usually, sewage has only 0.1% of solids, while remaining 99.9% is water. Majority of the organic matter in the sewage decompose by chemical and biological process. Sewage contains substantially the biodegradable organic matter, which undergoes aerobic or anaerobic biological decomposition.Usually municipal wastewater falls in low strength waste streams as it contains low organic loading content9,45.

A study was carried out for a lab scale UASB reactor of 5 litres to treat municipal wastewater (fortified)at temperature of 300C for optimization of Organic Loading Rate(OLR) and Hydraulic Residence/Loading Rate(HRT). The result indicated an optimum range of OLR was 7.2 to 10.8 kg/m3dwith 4 hours HRT and COD removal efficiency of about 85%46.

An investigation using a lab scale HUASB reactor (5.9 litres)was done for domestic wastewaterwith plastic cut rings as inert media for 110 days. Initially the HRT was 7.3 hr which was gradually decreased to 3.3 hr, achieved the Biochemical Oxygen Demand (BOD)and COD removal was 70-91% and75-86% respectively. In the biogas, 62±3% methane was noticed. Volatile Fatty Acids(VFA)measures within the range of 100 to186 mg/L, did not cause any issues like souring the reactor as well as increased nutrient levels were observed during the treatment. HUASB process can be appraised withremarkably low HRT of 3.3 hours, which will decrease the domestic wastewatertreatment chargeextensively33.

A technology comparison study between a UASB and a hybrid UASBï¬lter has studiedfor domestic wastewaterat various temperatures i.e.10, 14, 20 and 280C and varied organic loadings. A continuing COD reduction was observed for each mentioned temperature until the upflow-velocity was less than 0.35 m/h.Even in low temperate atmospheric conditions, UASB and also the hybrid UASB filter could be a good alternate for the treatment of domestic wastewater35.

Industrial Wastewater

Characteristics of wastewater may vary from industry to industry due to process dissimilarities. As an example, the amount of wastewater coming from a cooling tower is different than the wastewater generated during chemical process. Adversely, there are no many more differences in the quality of sewage, influenced by season, life style of individuals, sewage system, etc8,9.

Based on the concentration of BOD,COD, SS and nutrients like nitrogen (N) and phosphorus (P), industrial wastewater can be considered as low-strength, medium-strength, high-strength and extremely high-strength. In general, the powerful the effluent, the substantial the investment in treatment and energy feed in to execute sustainable treatment goal47.Accordingly, it calls for the use and analysis of numerous different processes.

Obviously, the characteristics of effluents arising from different industries falling under different groups, will vary widely. This can be realized from the data presented at Table1 for different industries. The characteristics of wastewater arising from different industries and hence varied processes fall under a wide spectrum in terms of physical, chemical and biological properties. These variations have been illustrated in Table 1 for a set of industries.

Table 1: Major Sources, Pollutants and Characteristics of Typical Industrial Wastewater.

Sr No. | Industry | Sources of Wastewater | Major Pollutants | Parameters ((mg/L) | Reference | ||

BOD | COD | SS | |||||

1 | Dairy, Milk Processing | Pasteurization, milk powder, butter, cheese, ice-cream, yogurt, dessert etc. preparation | Carbohydrates, Fats, Proteins9,48 9,48 | 600-1000 | 400-1800 | 200 | 9,48,49 |

2 | Slaughter House | Preprocessing, bleeding, slaughtering, evisceration | SS, Protein, Blood | 1500-2500 | - | - | 38 |

3 | Poultry Processing | Killing, Packing, Rendering etc. | SS, Protein | 500 - 800 | - | 800 | 9,48 |

4 | Distillery & Brewery | Industrial alcohol preparation,Fermentation, etc | COD, BOD, colour, SS | 850-1200 | 1700-2000 | 50-100 | 19 |

5 | Tannery | Soaking, Liming, Deliming, Washing, vegetable/chrome tanning, myrobing etc. | SS, Protein, sulphide | 1000-2000 | 2000-4000 | 2000- 3000 | 9 |

6 | Pharmaceutical | Fermentation, Extraction, Formulation | BOD, COD, SS | -- | -- | -- | 40,41,48 |

7 | Pulp and paper | Pulping & paper making | Colour, BOD, SS | -- | -- | -- | 9 |

8 | Sago | Sago processing | BOD, COD | -- | -- | -- | 31,50,51 |

9 | Textile | Washing, dyeing, printing, finishing etc. | Rectory organics, SS | 80-6000 | 150-12000 | 15-8000 | 9 |

The treatment processes applied widely depend on specific wastewater characteristics. The industries which generate wastewater with high concentration of biodegradable matter such as dairy processing, slaughter house, poultry processing, sago etc, extensively use biological treatments9,31,38,48–51. High SS generating industries like Pharmaceutical, tannery, pulp and paper, primarily use physico-chemical treatment operations40,48. Certain non-biodegradable compounds may also be generated apart from BOD, COD, SS etc. For instance, Textile processing industries use advanced processes such as adsorption, ion-exchange, chemical oxidation, electro chemical etc.9,48.

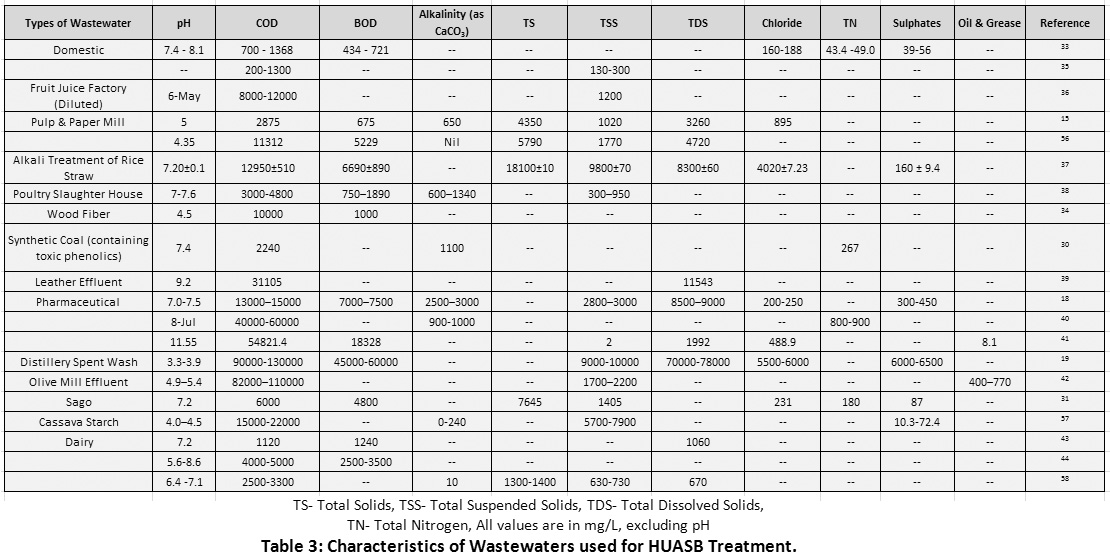

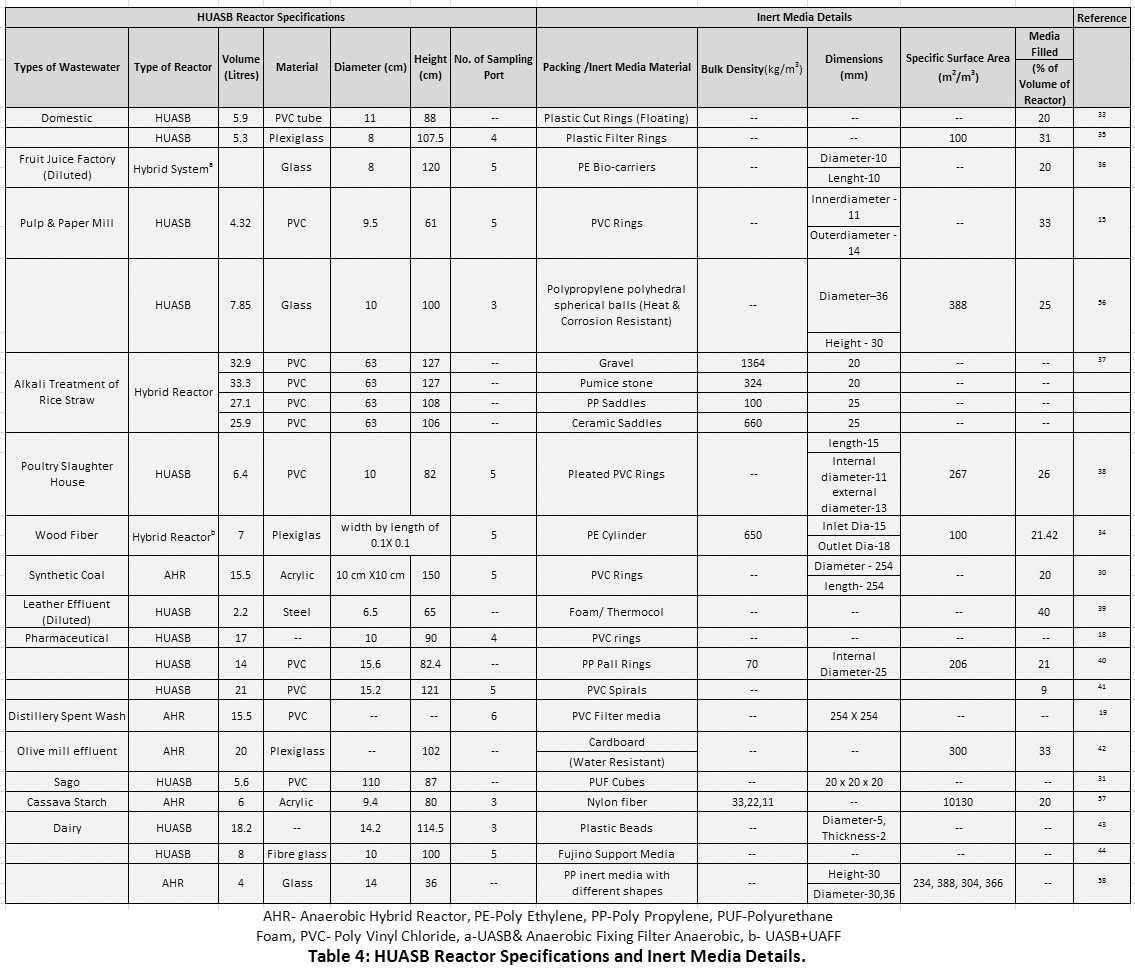

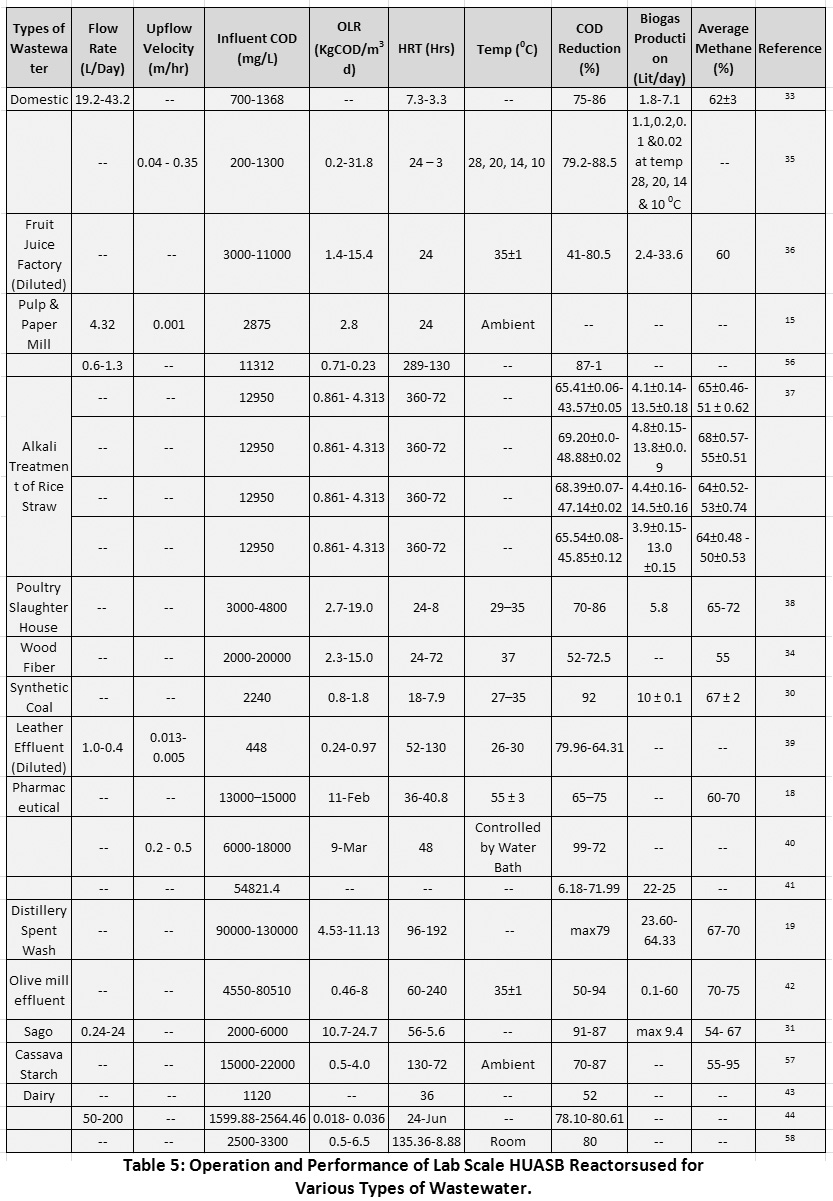

The operational parameters along with corresponding wastewater characteristics and the kind of inert media preferred have been highlighted in Table 3 to Table 5. These values have been derived experimentally from researches conducted on lab scale UASB reactors.

The increasing demand and subsequently decreasing freshwater reserves along with deteriorated water quality have forced the industries to consider treatments of higher efficiency, economic feasibility as well as the application of recycle and reuse concepts.

HUASB Treatment Initialization and Optimization

The starting up of the reactor is a complex process and also a determining factor for effective performance of anaerobic reactors2. It depends on various factors such as acclimatization of seed sludge along with pH, nutrients, organic loading rate, up-flow velocity, HRT, liquid mixing, presence of toxic compounds and reactor design duly effects the development of sludge bed29,52.Excellent performance of HUASB reactor is depending on the formation of well settled and greatly active granular sludge, with a high methanogenic activity.

Usually, startup period ranges from 3 weeks to 3 months at times. HRT is an important factor which affect the performance and efficiency of a reactor. The HRT is maintained to ensure proper and effective contact. Usually, acclimatization of the microbes to a substrate may obtain from 3 to 8 weeks. Satisfactorily acclimatized microbes show greater stabilities towards hydraulic overloads, variations in temperatures, volatile acids& ammonia concentrations etc.

Prolonged start-up periods along with instability are among the various operational problems associated with the operation of UASB and Upflow Anaerobic Fixed Film (UAFF) systems. Hence, a HUASB has been conceptualized which attempts to solve these problems whilst retaining the positive aspects of these reactors which include high cell concentration, tolerance to higher loading rates and good mixing34.

Generally start-up of an anaerobic reactor has been performed with cow dung manure17, active sludge of a dairy wastewater treatment plant29, fully fledged running existing UASB plant, etc. During the start-up of the reactor, shock loading was ignored to prevent the washout of microbial biomass17. An investigative study was started the two UASB reactors, first reactor seeded with cow dung manure, which needed 120 days to start up and second reactor seeded with active sludge of a dairy wastewater treatment plant, which was stabilized in a period of 80 days29.Table 2 illustrates the COD removal efficiency achieved along with subsequent start up times as the biomass inoculum is varied.

Table 2: Treatment Initializationof UASB/ HUASB Reactor.

Sr. No. | Start Up Seeding/Inoculums source | COD Removal Efficiency (%) | Start-up time | Reference |

1 | Cow Dung Manure | 81 | 120 days | 17 |

| Activated Sludge of Dairy Wastewater Treatment Plant | 81 | 80 days | 17 |

2 | Organic-Inorganic Hybrid Polymers with the Sewage Digester Sludge | 90 | 5 minutes | 16 |

3 | Active Biomass from a Biogas Plant | 90.8 | 84 days | 47 |

4 | PVA gel immersed in Sewage Digester Sludge | >87 | 14 days | 20,21 |

5 | Glucose addition in Acclimatized Biomass | 56-80 | -- | 18 |

6 | Septic Tank Sludge (Domestic) | 90 | -- | 53 |

Formation of granular sludge can make the reactor operation smooth. The long HRT are not suitable for sludge granulation in UASB reactors, on the other hand, due to very short HRT possibility of loss of microbial biomass arises22. Both the possibilities are adverse for efficient performance of the HUASB reactor, even though granulation has been noted to be important for effectivewastewater treatment in the reactors. Hence, in the efforts of solving this problem of proper and efficient granulation, various researchers have come up with studies and improvement concepts.

A study involved the use of PVA gel as a biocarrier in UASB reactor in order to enhance and optimize the granule formation20,21. PVA gel is composed primarily of Polyvinyl Alcohol. It has a porous structure that can trap and carry micro-organisms. It is composed of approximately 4 mm diameter spherical beads with 10 to 20 micron pores in each bead, each bead can hold up microorganisms up to 1 billion. It is insoluble in water and is non-biodegradable and it has no effect of temperature, acid and bases. In a similar study, PVAgel beads as biocarrier were employed in UASB reactor for synthetic wastewater treatment51. In 283 days of working, the OLR was gradually increased from 0.42 to 22.5 kgCOD/m3 with an inlet wastewater COD from 568 to 9100 mg/L at an HRT from 48 to 10 hours with COD removal efficiencies from 51 to 91%. At the end of the duration of study, the gel was blackened and significant granules were obtained along with the absence of filamentous bacteria of the PVC gel surface or even the inside. The PVAgel granules were found to have average settling velocity of 200 m/h (5 cm/s) along with biomass attachment rate of 0.93 g Volatile Suspended Solids/g PVAgel.

The HUASB reactor suggests positive aspects such as higher OLRs with reduced hydraulic residence time and significantly lower energy requirements20,38,40. The reliance of output characteristics such as biogas generation, sludge volume etc. have been determined using mathematical models involving Fuzzy rule which attempts to quantify the interdependence of input and output parameters54,55. Anaerobic Digestion Model 1 (ADM1) has been studied in order to determine desirable effluent characteristics and agitation requirements10.

Table3 provides information about the varied characteristics of different types of wastewater. It includes the values of various wastewater parameters which are to be measured before the treatment for investigating the working efficiency of the treatment and take steps to inculcate the required changes in the design as well as operation.

| Table 3: Characteristics of Wastewaters used for HUASB Treatment. Click here to view Table |

| Table 4: HUASB Reactor Specifications and Inert Media Details. Click here to view Table |

| Table 5: Operation and Performance of Lab Scale HUASB Reactorsused for Various Types of Wastewater. Click here to view Table |

HUASB Performance Control Parameters

pH, Alkalinity and Volatile Acids

The microbes or bacteria in the anaerobic reactor are sensitive to pH value alterations. Corresponding to the various stages of biogas production, the major bacteria involved are: Bacteria involved in hydrolysis, acidogenesis and methanogenesis. An optimum pH has to be maintained in order to keep the reactor from malfunctioned performance. Both the acid and methane producing bacteria work on different pH range i.e 5.0 to 6.0 and 6.7 to 7.4 respectively. The lowering of pH caused by acid producing bacteria is counter balanced by the bicarbonate released from the activity of methane producing bacteria. Hence, researches have conclusively proved that for unhindered functioning of a reactor, the pH has to be balanced accordingly59,60.

In the conditions of prevailing low pH from the activity of acid producing bacteria, high molecular weight acids are accumulated causing the event of “SOUR/STUCK Reactor”. In order to remediate the low pH, various alkaline additives can be utilised such as NaOH (Sodium Hydroxide), CaO (Quick lime), NaHCO3 (Sodium Bicarbonate), Na2CO3 (Sodium Carbonate), Ca(OH)2 (Slaked/ Hydrated lime), NH4HCO3 (Ammonium Bicarbonate) etc8,13.

Due to slow growth & sensitiveness of methanogens they are often unable to convert short chain fatty acids into methane resulting in accumulation of organic acids in the reactor resulting further decrease in the working of the reactor. Various studies have reported accumulation of high VFA concentration i.e. 480mg/L and the effluent pH lowered to 5.0, which reserved methanogens activity36. Upon experimentation it was concluded that acetic acid concentrations noticed up till 4000 mg/L does not adversely affect gas production. Therefore VFA should be considered as an important parameter for smooth optimum reactor performance25. To manage the VFA concentration in the system, alkalinity can be accurately maintained by circulating treated wastewateror addition of lime or Quick lime or Slaked/ Hydrated lime, Sodium Carbonate/Biocarbonate, etc36. However, it was suggested that higher hydraulic circulation does not lead to effective removal of COD from the influent water, and can actually cause a significant decrease in the effectiveness of the reactor36.

A multistage bio-film reactor (anaerobic) was designed on lab scale to treat medium strength wastewater having 54 L operative volume. The wastewaterevidently carried molasses are various influent conditions. At a mesophilic temperature of 35oC, the start up time, stability as well as the performance was assessed. At varied OLRs of 3.0, 4.5, 6.75 and 9.0 kg COD/m3, corresponding percentage COD removal achieved was 91.6,91.6, 90.0 and 88.3 respectively. The effects of toxic shock were assessed as well which showed that the prime advantage of employing this type of bioreactor is because of the compartment structure61.

While treating wood fibre wastewater in a lab scale HUASB reactor, the influent pH was obtained 4.5 and lime was added to control the same pH for the entire study34.Also the influent pH of the Distillery Spent Wash was also neutralised from 3.3 -3.7 using lime solution19. While treating the simulated coal wastewater containing toxic phenolics in an UASB and an AHR, the influent alkalinity was corrected and maintained to 1100 mg/L by adding sodium bi-carbonate in both the reactors30.

While treating wood fibre wastewater in a lab scale HUASB reactor, the influent pH was obtained 4.5 and lime was added to control the same pH for the entire study 34.Also the influent pH of the Distillery Spent Wash was also neutralised from 3.3 -3.7 using lime solution19. While treating the simulated coal wastewater containing toxic phenolics in an UASB and an AHR, the influent alkalinity was corrected and maintained to 1100 mg/L by adding sodium bi-carbonate in both the reactors30.

Working Temperature

The process of anaerobic digestion is sensitive to changes in temperature. Microbial assisted methane generation occurs in a specific thermal range of 0 to 970C. The digestion process requires two stage thermal conditions namely, Mesophilic (30 to 40 0C) and thermophilic (50 to 550C) but methanogenesis can occur at temperature as low as 12 to 15 0C13.Upon temperatures lowering below 30oC, activity of methane producing bacteria is adversely affected. Table5 highlights the operating temperature for Lab Scale HUASB Reactors used for various types of wastewaters and it clearly shows that most of the authors operated their hybrid reactors in a mesophilic temperature range. Thermophilic processes have long been preferred due to the wide range of advantages they provide, which include, an enhanced organic solids degradation rate, better phase separation, no cooling mechanism of effluent required, increased rate of gas production along with simultaneous removal of pathogenic organisms.

An HUASB performance was studied for the bulk treatment of pharmaceutical discharge water (Thermophilic conditions). The reactor was subjected to a thermophilic temperature range of (55±3 °C) surrounded with a liquid envelope (usually water). Recirculation of heated water was carried out through the jacket. After about 200 operation days, the properties of the granular sludge accumulated at the bottom of the reactor were analyzed by the scanning electron microscope. The sizes of sludge granules before and after the treatment were recorded and measured. The size was increased significantly after treatment. The optimum temperature for the growth of methanothrix and methanosarcina were also recorded which were 60–65 °C and 50–58 °C respectively. Hence, it was concluded that thermophilic conditions provide a more efficient treatment of such wastewater18.

In spite of the increased benefits, thermophilic microbes exhibit a high sensitivity to rapid changes in influent characteristics, pH of the reactor, OLR along with other factors which makes the startup and operation a little difficult. Hence, it has been made a general practice to make the change from mesophilic to thermophilic situations by a lengthy decrease in the methane generation. An approach involving the operation of the system at and 80% COD reduction is being used for the start-up, which is generally reached by adjusting the OLR25,60

Temperature considerably influences the growth and survival of microorganisms within a reactor system. Anaerobic treatment can be carried out at various ranges of temperature which are psychrophilic, mesophilic and thermophilic; studies have found that certain low temperature affect the maximum specific growth rate along with methanogenic activity1,25.

The sustenance of microorganisms in the reactor is largely affected by the prevalent temperature. Anaerobic treatment can be carried out at various ranges of temperature which are psychrophilic, mesophilic and thermophilic; studies have found that certain low temperature affect the maximum specific growth rate along with methanogenic activity1,25.

The methanogenic activity significantly reduces; about 10 to 20 times as compared to that at 35oC which in turn requires an increase in the quantity of biomass present in the reactor or a change in HRT and Solid Retention Time(SRT) for maintaining the performance of COD reduction with that as obtained at 350C23,25,62. It is being argued that a decrease in temperature subsequently slows down the hydrolysis process as well as decreases the maximum growth along with substrate utilization rates1.

OLR, COD Removal Efficiencies with Biogas Production

Organic loading rate is a crucial parameter which extensively affects the microbial ecology and performance of HUASB reactor. The OLR is the mass of organic matter loaded per day per crosssection area of the reactor. The degree of microbial growth in a biological process is largely OLR dependent. A high OLR value causes rapid microbial growth but it runs with intoxication risk, whilst a significantly low OLR may cause bacterial starvation. OLR incorporate reactor elements, working parameters, and the activity of bacterial mass into the volume of media25,60.

Table 5 depicts the various OLRs, COD removal efficiency and biogas production reported by various researchers using HUASB reactors for various types of wastewater. A different studies have confirmed that increase in OLRs results to decrease in COD removal efficiency with various types of wastewater in HUASB reactors31,37,39,40. On the other hand, during optimization of OLR with COD removal efficiency, it has also observed to be proportional18,34–36,38,42,44.

According to various studies, high HRT have been correlated with higher COD removal efficiency, provided that the OLR are not on the extremely higher sides. In addition to this, mesophilic temperature range results in a higher COD removal efficiency.

However, gas production would be increased with high rate of OLR but the methanogens could not work fast so that conversion of acetic acid to methane should be maintained. Undoubtedly, OLR is highly relay on HRT and substrate concentration, therefore, it is necessary to maintain balance between these two parameters for high efficiency of the reactor25.It is examined from the table 5 that average methane content in the biogas production ranges between 50 to 75% that shows large variations in the study. The methane gas produced reported on the bases of substrate utilization and biomass production.

Flow Rate, HRT & Upflow Velocity

Flow rate is also a significantly considered as the key operating parameter which directly co-relate with the HRT. The HRT is the average time for which the influent water is retained inside the digestor and is computed by taking the ratio of reactor volume and influent flow value.

The HRT is a crucial operating parameter as it related to the velocity of digestion and also relates to the size of the reactor. The HRT can possibly fluctuate between 6 to 20 hours for the average temperature value, in correspondence to the wastewatercharged. Experimental studies were conducted by operating the reactor at a higher temperature of 25oC with highly alkaline domestic sewage, and the results showed that a 4 hour HRT did not adversely alter the operational stability of the reactor.

For designing purpose, HRT can be obtained by dividing the reactor volume to the flow rate. Calculations should be performed while keeping in mind the volume in the reactor occupied by granules.

The velocity (up-flow) mentioned here is the velocity of the liquid in the reactor for a cross section area. With increase in up-flow velocity, significant reduction in developed biomass film60.

In a reactor treating wastewater, inlet influent is charged with a uniform velocity, however, however the flow is disrupted by sludge granules as well as the agitation by gas bubbles. Therefore, it is necessary to find out the hydrodynamic behaviour of the reactor and this phenomenon is determined by Residence Time Distribution (RTD) study. RTD studies have been performed at both start up and end by employing a tracer of Lithium Chloride38. RTD study has revealed that the flowpattern was in a mixed regime at the time of completion of the study.

Tracer studies were performed using a Rhodamine 6G dye and RTD curves were Plotted for UASB and AHR systems in phenolic wastewater treatment30. The study indicated that a completely mixed flow pattern in UASB and a plug flow pattern in the AHR correspondingly.

The COD removal of the reactor is a function of the characteristic of the effluent which are enlisted in correspondence to the HUASB configuration in table 4 and table 5.

Inert Media Used

The inert media usage is directed towards enhanced reactor performance in the HUASB. Since the type of the inert media used for biomass fixation in the AHRs is an important parameter with respect to the performance of the reactor, while designing the inert media, size, shape, basic material,porosity, surface roughness, bulk density and the specific surface areaare given significance58.

The effect of packing/inert media plays a very important role in HUASB reactor. Various researchers have attempted the different kind of packing media like PVC/ Plastic Rings15,18,19,30,33,35,38,Poly Ethylene Bio-carriers36, Gravel,Pumice stone, Polypropylene Saddles, Ceramic Saddles37, Foam, Thermocol39, PP Pall Ring40, PVC Spirals41, Cardboard (Water Resistant)42, PUF Cubes31, Plastic Beads43, nylon fibers57etc.in a various shapes like circular, square, rectangular, spherical, cylindrical or even irregular shape. Lab Scale HUASB Reactor Specifications & Packing Media Details used for various types of wastewaters by various researchers has represented in table4. Usually packing media resembling various materials has been used for attached growth process and it is accumulated in the range of 10 to 40 % of total volume of the reactor.

Microbial activity depends upon the surface area of the media used. Table 4 highlights that surface area of the media used ranging from 100 to 10,300 m2/m3 and bulk density was observed to be of 70 to 1364 kg/m3. The quantity and volume of the inert media plays a significant role in the pollution reduction efficiency as biomass retain inside the reactor. Inert media provide a place for biomass attachment and also act as a solid gas separator57.

A study was performed forwastewater from rice straw treatment by alkali with AHRs. Varied packing materials were used such as gravel, ceramic and polypropylene saddles. The results were promising by using pumice stone than any other two mediums. The reactors were investigated with varying OLR (0.861 to 4.313 gCOD/Ld) and HRT (3 to 15 days). A comparatively better COD removal as achieved (69.2 %) along with 0.153LCH4/gCOD (Methane output) with pumice stone. The results further imply that a 5 day optimum HRT can be successfully applied37.

Post Treatment for Enhanced Output

In spite of great advantages, effluents from the HUASB can rarely fulfill the stringent effluent disposal standards decided by the governing institutions. Hence, a post treatment process is inevitable in order to conform to the set standards11,63. The national standards differ from country to county. Israel is the world leader in water recycling and reuse sector. Therefore, Israel has a more rigid system of standards as compared to that in India. The level of stringency is the function of the development of a country and the available technological know-how.

The final effluent characteristics also depend on the way on which it is to be used. The general approach in India is to use the treated wastewater for irrigation of vegetative lands or discharge in surface water bodies. Therefore, to justify these needs, effluent discharge limits for some important parameters like for COD, BOD, TSS, Faecal Coliform i.e.MPN/100 ml, total Nitrogen and ammonical nitrogen are 50, 10, 20, 100, 10 and 5 respectively, prescribed by the National Green Tribunal (NGT) notification dated 30/04/2019.

The prime function of posttreatment is to remove organic matter and its constituents which are scarcely removed by any anaerobic treatment, for example nitrogen and phosphorous along with pathogens such as bacteria, protozoans, virusesand helminthes13. An effluent suitable for a discharge to water bodies cannot be essentially achieved by a single anaerobic process. For agricultural reuse, the effluent from HUASB has to be further treated i.e post treatment system to attain the disposal norms.

Different aerobic post-treatment methods have been investigated for UASB/HUASBreactor like micro aeration methods i.e. flash aeration, activated sludge process, continuous diffused aeration , trickling filters, rotating biological contractors, sequencing batch reactor, aerobic fluidized batch reactor, submerged aerated bio filters, aerated fixed bed reactor64, physicochemical processes such as flotation11,63,65,moving bed bio film reactor66,67, coagulation and flocculation68, down flow hanging sponge69–71, self-aerated sponge tower72, slow sand filtration73, ultrafiltration74,75, Continuous electro coagulation process76, solar photo-fenton process77and natural treatment systems such as constructed wetlands63,78 and stabilizationpond63. The integrated coagulation-flocculation (using Ferric Chloride& Polymers)followed by UASB and regenerable Zeolite process was studiedfor low cost treatment23. Activated sewage sludge containing iron & aluminum oxides as a coagulant can be reused79. The main mechanisms through which organic matter and solids removed are bio-oxidation, sedimentation and filtration.

While some of these post treatment methods are energy demanding whereas some others like polishing ponds/stabilization ponds require huge area, and thus the choice of aproper, reliable and efficient post-treatment method is a greatchallenge to researchers and industries80.

Recently some of the researchers have attempted the anaerobic treatment i.e. UASB/HUASB with advance oxidation treatment and robe bed biofilm reactor for municipal wastewater. The following section briefly explains these post treatment options, which can also be applied to any typewastewater after detailed study.

A lab scale investigation was performed on combined treatment of anaerobic i.e. HUASB and solar photocatalytic methods (i.e. TiO2) to treat domestic wastewater. At stage I, a HUASB was implemented in a recirculation approach for about 3 days which founds one cycle and subsequently 30 cycles were noted to find out the relative stability of the anaerobic treatment. It took 90 days for stabilization using recirculation. The wastewater from HUASB reactor is passed to a solar photo-catalytic oxidation process. The optimum pH and catalyst loading were observed to be 5 and 200mg/L respectively. The overall COD removal for both the technologies was observed to be 96%32.

Researchers have designed a novel hybrid UASB followed by Moving Bed Biofilm Reactor as a subsequent treatment and Rope Bed Biofilm Reactor as last treatment option. The entire combine system wasoperated in continuous mode for about a year for organic matter & nitrogen removal from sewage with COD of 500 mg/L. More than 99% of organic matter was removed & total nitrogen removal of 89% was obtained. Sludge washout problem can be efficiently eradicated by adding media. Maximum biogas production of 0.61 m3/kg&COD removed achieved at an OLR of 2 kgCOD/m3d. Thus, an efficient carbon and nitrogen removal system was developed81.

A study was conducted on startup of UASB reactor followed by advanced oxidation process for municipal wastewater. This study was majorly conducted to minimize the time required for start-up of the lab scale UASB reactor with a working volume of 4.4 lit. Two different nutrients were used during the UASB start-up period for 39 days. Upon reaching the ultimate COD removal of 99%, the influent was changed to municipal wastewater with a COD of 250 to 350 mg/L. The HRT was reduced gradually (from 48 to 6 hours). Further the UASB effluent was treated with (optimized dose of 2 ml/L) 40% hydrogen peroxide. The entire integrated treatment system was noticed to reduce the COD by 99%, TSS by 73%, total nitrogen by 84% and turbidity by 67%53.

Performance of combined anaerobic (packed bed UASB) - aerobic (biological aerated filter) was investigated for sewage treatment at a temp ranging from 10-40oC at a reactor volume of 2.2 m3 for 2 years. A polyester fabric (nonwoven) was used as a packing material and the BOD, TSS and COD removal rates were found to be 90.6%, 92.4% and 88.9%. Whilst better results were found in summer, the system was also found to eradicate 4 logs of total and fecal coliforms. The quality of the treated sewage complies with the Egypt’s National Regulatory Standards for irrigation reuse water82.

A pilot-scale UASB-moving bed biofilm reactor followed by a high-rate algal pond to remove organic matter,nutrients and pathogen from sewage to facilitate reuse83.

Sustainable Aspect of HUASB Technology

Environmental Dimension

The concepts of circular economy can be well implemented in the area of wastewater treatment (both domestic and industrial) due to the anaerobic nature of the process and the ultimate production of biogas which can be utilized generation of electricity2,4. This process further allows the application of a co-benefit approach of achieving eco innovation, safe wastewater treatment and disposal along with clean energy generation4. The HUASB system is aimed at optimizing the process to increase methane production and sludge volume reduction33,49.

Social Dimension

The application and enhancement of Ecosystem Services is necessary for social acceptance of an engineering or design solution to pollution problems84. Extent of application and operation increases as the technology is hybridized to eradicate undesirable effluents and the subsequent need for their disposal.

Economic Dimension

Ultimate success of an engineering solution lies in its economic feasibility. These benefits can be well derived using evaluative techniques such as life cycle assessment, due diligent auditing and resource flow analysis85.An integrated method of using these methods in conjunction with performance analysis and development tools such as Eco-innovation Development and Implementation Tool2,86.

Conclusions

Different HUASB reactors and corresponding post treatment options for domestic and industrial wastewater have been meticulously investigated and reviewed. The optimum conditions of operation for quick start up have also been summarized and studied. By varying the inert media along with essential operating parameters like pH, temperature, HRT, OLR, the efficiency of HUASB reactor can be improved significantly. This review study found that by using different inert media in the range of 10-40% of reactor volume, the COD removal efficiency can be achieved by 41-99% along with methane content of 50-75% biogas produced.

Various combination of aerobic & anaerobic wastewater treatment technologies shows promising results for optimal pollution reduction. Treated effluent from HUASB reactor usually given post treatment in order to enhance pollution removal efficiency. Various post treatment options such as HUASB followed by aerobic processes, advanced oxidation process, chemical processes, membrane modules, physical process etc. needs to be investigated for wastewater recycling & reuse.

In India, after successful implementation of UASB technology in industries, it is also being appliedfor domestic wastewater treatment to save subsequent aeration costs. In addition to this, the purification of generated biogas is costlier than using conventional energy sources and hence it is a challenging task. HUASB technologies feasible for large scale implementation are still being researched on lab and pilot scale reactors. The positive aspect of UASB is that it can be applied in a decentralized manner with reduced footprint for densely populated areas.

Acknowledgment

Special thanks go to the staff at the Environmental Engineering Department, L. D. College of Engineering, Ahmedabad for providing valuable information and contribution to this comprehensive review paper.

References

- Daud MK, Rizvi H, Akram MF, et al. Review of upflow anaerobic sludge blanket reactor technology: Effect of different parameters and developments for domestic wastewater treatment. J Chem. 2018;2018. doi:10.1155/2018/1596319.

CrossRef - Aiyuk S, Forrez I, Lieven DK, van Haandel A, Verstraete W. Anaerobic and complementary treatment of domestic sewage in regions with hot climates—A review. Bioresour Technol. 2006;97(17):2225-2241. doi:10.1016/j.biortech.2005.05.015.

CrossRef - Khajuria A. Application on Reuse of Wastewater to Enhance Irrigation Purposes. Univers J Environ Res Technol. 2015;5(2):72-78. www.environmentaljournal.org.

- Mainardis M, Buttazzoni M, Goi D. Up-Flow Anaerobic Sludge Blanket (UASB) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering. 2020;7(2):43. doi:10.3390/bioengineering7020043.

CrossRef - Powar MM, Kore VS, Kore S V, Kulkarni GS. Review on Applications Of UASB Technology for Wastewater Treatment. Int J Adv Sci Eng Technol. 2013;2(2):125-133.

- Jamwal P, Mittal AK. Reuse of treated sewage in Delhi city: Microbial evaluation of STPs and reuse options. Resour Conserv Recycl. 2010;54(4):211-221. doi:10.1016/j.resconrec.2009.08.002.

CrossRef - Jhansi SC, Mishra SK. Wastewater Treatment and Reuse: Sustainability Options. Cons J Sustain Dev. 2013;10(1):1-15. doi:10.7916/D8JQ10Q1

- Metcalf & Eddy. Wastewater Engineering: Treatment and Reuse. McGraw-Hill Publ Co. 2004;(4).

- Varandani NS. Environmental Engineering Principles and Practices. Pearson India Education Services Pvt. Ltd.; 2017.

- Dutta A, Davies C, Ikumi DS. Performance of upflow anaerobic sludge blanket (UASB) reactor and other anaerobic reactor configurations for wastewater treatment: a comparative review and critical updates. J Water Supply Res Technol. 2018;67(8):858-884. doi:10.2166/aqua.2018.090.

CrossRef - Khan AA, Gaur RZ, Tyagi VK, et al. Sustainable options of post treatment of UASB effluent treating sewage: A review. Resour Conserv Recycl. 2011;55(12):1232-1251. doi:10.1016/j.resconrec.2011.05.017.

CrossRef - G.Lettinga. Sustainable integrated biological wastewater treatment. Water Sci Technol. 1996;33(3):85-98. doi:10.1016/0273-1223(96)00303-4.

CrossRef - de Lemos Chernicharo CA. Anaerobic Reactors. Water Intell Online. 2015;6(0):9781780402116-9781780402116. doi:10.2166/9781780402116.

CrossRef - Ramdhanie I, Chakrabarti DP. Studies on the Design, Evaluation, and Energy Conservation Potential of a Pilot-Scale Hybrid Uasb Treating a Combination of Waste Activated Sludge and Distillery Spent Wash. Chem Eng Commun. 2014;201(6):804-833. doi:10.1080/00986445.2013.791812.

CrossRef - Subramani T, Krishnan S, Kumaresan PK, P. Selvam. Treatability Studies on Hybrid Up-Flow Anaerobic Sludge Blanket Reactor for Pulp and Paper Mill Wastewater. Int J Mod Eng Res. 2012;2(3):602-606.

- Jeong HS, Kim YH, Yeom SH, Song BK, Lee S Il. Facilitated UASB granule formation using organic-inorganic hybrid polymers. Process Biochem. 2005;40(1):89-94. doi:10.1016/j.procbio.2003.11.041.

CrossRef - Rajathi RP. Efficiency of HUASB Reactor for Treatment of Different Types of Wastewater - A Review. Int J Eng Res Technol. 2013;2(12):465-472.

- Sreekanth D, Sivaramakrishna D, Himabindu V, Anjaneyulu Y. Thermophilic treatment of bulk drug pharmaceutical industrial wastewaters by using hybrid up flow anaerobic sludge blanket reactor. Bioresour Technol. 2009;100(9):2534-2539. doi:10.1016/j.biortech.2008.11.028.

CrossRef - Gupta SK, Gupta SK, Singh G. Anaerobic hybrid reactor: A promising technology for treatment of distillery spent wash. Int J Environ Pollut. 2010;43(1-3):221-235. doi:10.1504/IJEP.2010.035926.

CrossRef - Pandey S, Sarkar S. Anaerobic treatment of wastewater using a two-stage packed-bed reactor containing polyvinyl alcohol gel beads as biofilm carrier. J Environ Chem Eng. 2017;5(2):1575-1585. doi:10.1016/j.jece.2017.02.013.

CrossRef - Wenjie Z, Dunqiu W, Yasunori K, Taichi Y, Li Z, Kenji F. PVA-gel beads enhance granule formation in a UASB reactor. Bioresour Technol. 2008;99(17):8400-8405. doi:10.1016/j.biortech.2008.02.040.

CrossRef - Aiyuk S, Verstraete W. Sedimentological evolution in an UASB treating SYNTHES, a new representative synthetic sewage, at low loading rates. Bioresour Technol. 2004;93(3):269-278. doi:10.1016/j.biortech.2003.11.006.

CrossRef - Aiyuk S, Amoako J, Raskin L, Van Haandel A, Verstraete W. Removal of carbon and nutrients from domestic wastewater using a low investment, integrated treatment concept. Water Res. 2004;38(13):3031-3042. doi:10.1016/j.watres.2004.04.040.

CrossRef - Nnaji CC. A review of the upflow anaerobic sludge blanket reactor. Desalin Water Treat. 2014;52(22-24):4122-4143. doi:10.1080/19443994.2013.800809.

CrossRef - Latif MA, Ghufran R, Wahid ZA, Ahmad A. Integrated application of upflow anaerobic sludge blanket reactor for the treatment of wastewaters. Water Res. 2011. doi:10.1016/j.watres.2011.05.049.

CrossRef - Seghezzo L, Zeeman G, Van Lier JB, Hamelers HVM, Lettinga G. A review: The anaerobic treatment of sewage in UASB and EGSB reactors. Bioresour Technol. 1998. doi:10.1016/S0960-8524(98)00046-7.

CrossRef - Rizvi H, Ali S, Yasar A, Ali M, Rizwan M. Applicability of upflow anaerobic sludge blanket (UASB) reactor for typical sewage of a small community: its biomass reactivation after shutdown. Int J Environ Sci Technol. 2018;15(8):1745-1756. doi:10.1007/s13762-017-1537-2.

CrossRef - Elmitwalli TA, Sklyar V, Zeeman G, Lettinga G. Low temperature pre-treatment of domestic sewage in an anaerobic hybrid or an anaerobic filter reactor. Bioresour Technol. 2002;82(3):233-239. doi:10.1016/S0960-8524(01)00191-2.

CrossRef - Rizvi H, Ahmad N, Abbas F, et al. Start-up of UASB reactors treating municipal wastewater and effect of temperature/sludge age and hydraulic retention time (HRT) on its performance. Arab J Chem. 2015;8(6):780-786. doi:10.1016/j.arabjc.2013.12.016.

CrossRef - Ramakrishnan A, Surampalli RY. Comparative performance of UASB and anaerobic hybrid reactors for the treatment of complex phenolic wastewater. Bioresour Technol. 2012;123:352-359. doi:10.1016/j.biortech.2012.07.072.

CrossRef - Rajesh Banu J, Kaliappan S, Beck D. High rate anaerobic treatment of Sago wastewater using HUASB with PUF as carrier. Int J Environ Sci Technol. 2006;3(1):69-77. doi:10.1007/BF03325909.

CrossRef - Rajesh Banu J, Kaliappan S, Do KU, James A, Yeom IT. Combined treatment of domestic wastewater using anaerobic and solar photocatalytic treatment. Water Qual Res J Canada. 2009;44(4):393-398. doi:10.2166/wqrj.2009.039.

CrossRef - Banu JR, Kaliappan S, Yeom IT. Treatment of domestic wastewater using upflow anaerobic sludge blanket reactor. Int J Environ Sci Technol. 2007;4(3):363-370.

CrossRef - Ayati B, Ganjidoust H. Comparing the efficiency of UAFF and UASB with hybrid reactor in treating wood fiber wastewater. J Environ Heal Sci Eng. 2006;3(1):39-44. http://ijehse.tums.ac.ir/index.php/jehse/article/view/69/68.

- Lew B, Tarre S, Belavski M, Green M. UASB reactor for domestic wastewater treatment at low temperatures: A comparison between a classical UASB and hybrid UASB-filter reactor. Water Sci Technol. 2004;49(11-12):295-301. doi:10.2166/wst.2004.0865.

CrossRef - Zhang Y, Ma Y, Quan X, Jing Y, Dai S. Rapid startup of a hybrid UASB-AFF reactor using bi-circulation. Chem Eng J. 2009;155:266-271. doi:10.1016/j.cej.2009.08.005.

CrossRef - Narra M, Balasubramanian V, Mehta H, Dixit G, Madamwar D. Performance evaluation of anaerobic hybrid reactors with different packing media for treating wastewater of mild alkali treated rice straw in ethanol fermentation process. Bioresour Technol. 2014;152:59-65. doi:10.1016/j.biortech.2013.10.071.

CrossRef - Rajakumar R, Meenambal T, Saravanan PM, Ananthanarayanan P. Treatment of poultry slaughterhouse wastewater in hybrid upflow anaerobic sludge blanket reactor packed with pleated poly vinyl chloride rings. Bioresour Technol. 2012;103(1):116-122. doi:10.1016/j.biortech.2011.10.030.

CrossRef - Murugesan EMP, Selvarasu P. Experimental Investigation of HUASB Reactor for Treatment Characteristics of Leather Effluent with Varying of Different Operating Parameters. Int J ChemTech Res. 2017;10(6):478-484.

- Oktem YA, Ince O, Sallis P, Donnelly T, Ince BK. Anaerobic treatment of a chemical synthesis-based pharmaceutical wastewater in a hybrid upflow anaerobic sludge blanket reactor. Bioresour Technol. 2008;99(5):1089-1096. doi:10.1016/j.biortech.2007.02.036.

CrossRef - Trivedi RD, Patel RB, Vyas DDS, Patel SM. Performance Evaluation of Hybrid UASB Reactor for Treatment of Pharma Industry Wastewater. Int J Sci Res Dev. 2015;3(1):835-838.

- Azbar N, Tutuk F, Keskin T. Biodegradation performance of an anaerobic hybrid reactor treating olive mill effluent under various organic loading rates. Int Biodeterior Biodegrad. 2009;63(6):690-698. doi:10.1016/j.ibiod.2009.02.009.

CrossRef - Gundkal PS, Bagawan SA, Hogarti MJ, Patil OV, Bannur RR. Treatment of Dairy Industry Wastewater by Hybrid Upflow Anaerobic Sudge Blanket Reactor. Int J Eng Res Technol. 2019;6(9).

- Lavanya R, Jodhi C. Evaluation Studies on Hybrid up Flow Anaerobic Sludge Blanket Reactor for Treating Dairy Effluent under Different Season . Int J Eng Res Appl. 2016;6(3):61-66.

- Sikosana ML, Sikhwivhilu K, Moutloali R, Madyira DM. Municipal wastewater treatment technologies: A review. Procedia Manuf. 2019;35:1018-1024. doi:10.1016/j.promfg.2019.06.051.

CrossRef - Hazrati H, Shayegan J. Optimizing OLR and HRT in a UASB reactor for pretreating high- Strength municipal wastewater. Res Gate. 2011;24(January). doi:10.3303/CET1124215

- Venkatesh KR, Rajendran M, Murugappan A. Start-Up Of An Upflow Anaerobic Sludge Blanket Reactor Treating Low-Strength Wastewater Inoculated With Non-Granular Sludge. Int Ref J Eng Sci. 2013;2(5):46-53.

- A.D. Patwardhan. Industrial Waste Water Treatment Technology.; 2008.

- Thenmozhi R, Uma RN. Performance Evaluation of Hybrid Upflow Anaerobic Sludge Blanket Reactor in the Treatment of Dairy Waste Water. Int J Biotechnol. 2013;2(5):105-112.

- Saravanane R, Murthy DVS, Krishnaiah K. Anaerobic treatment and biogas recovery for sago wastewater management using a fluidized bed reactor. Water Sci Technol. 2001;44(6):141-146. doi:10.2166/wst.2001.0360.

CrossRef - Sathyamoorthy GL. A novel approach to treat sago industrial wastewater using anaerobic hybrid reactor (AHR). Int J Civ Eng Technol. 2017;8(7):1229-1238.

- Zhang SJ, Liu NR, Zhang CX. Study on the Performance of Modified UASB Process Treating Sewage. Adv Mater Res. 2012;610-613:2174-2178. doi:10.4028/www.scientific.net/AMR.610-613.2174.

CrossRef - Bhatti ZA, Maqbool F, Malik AH, Mehmood Q. UASB reactor startup for the treatment of municipal wastewater followed by advanced oxidation process. Brazilian J Chem Eng. 2014;31(3):715-726. doi:10.1590/0104-6632.20140313s00002786.

CrossRef - Dholawala MJ, Christian RA. Prediction of biogas production in upflow anaerobic sludge blanket reactor based on fuzzy rule. Int J Sustain Dev Plan. 2020;15(5):721-733. doi:10.18280/ijsdp.150514.

CrossRef - Zamparas M, Kapsalis VC, Kyriakopoulos GL, et al. Medical waste management and environmental assessment in the Rio University Hospital, Western Greece. Sustain Chem Pharm. 2019;13(April):100163. doi:10.1016/j.scp.2019.100163.

CrossRef - Hemalatha D, Keerthinarayana S. Kinetic modelling of hybrid upflow anaerobic sludge blanket reactor in treatment of pulp and paper mill wastewater. 2017;24(May):352-357.

- Chaiprasert P, Suvajittanont W, Suraraksa B, Tanticharoen M, Bhumiratana S. Nylon fibers as supporting media in anaerobic hybrid reactors: It’s effects on system’s performance and microbial distribution. Water Res. 2003;37(19):4605-4612. doi:10.1016/S0043-1354(03)00422-6.

CrossRef - Sathyamoorthy GL. Substrate Removal Kinetics for Anaerobic Hybrid Reactor (AHR) Treating Dairy Industrial Wastewater. Int J Recent Technol Eng. 2019;7(4S):234-240.

- Zhang L, De Vrieze J, Hendrickx TLG, et al. Anaerobic treatment of raw domestic wastewater in a UASB-digester at 10 °C and microbial community dynamics. Chem Eng J. 2018;334:2088-2097. doi:10.1016/j.cej.2017.11.073.

CrossRef - Raúl Rodríguez Gómez. Upflow Anaerobic Sludge Blanket Reactor: Modelling. R Inst Technol Stock Sweden. November 2011.

CrossRef - Ghaniyari-benis S, Borja R, Monemian SA, Goodarzi V. Anaerobic treatment of synthetic medium-strength wastewater using a multistage biofilm reactor. Bioresour Technol. 2009;100(5):1740-1745. doi:10.1016/j.biortech.2008.09.046.

CrossRef - Abd Kadir MA, Abdul Latiff AA, Daud Z. Kinetics Study of UASB and HUASB System in Treating Municipal Wastewater. Appl Mech Mater. 2015;773-774:1173-1177. doi:10.4028/www.scientific.net/AMM.773-774.1173.

CrossRef - Mungray AK, Murthy ZVP, Tirpude AJ. Post treatment of up-flow anaerobic sludge blanket based sewage treatment plant effluents: A review. Desalin Water Treat. 2010;22:220-237. doi:10.5004/dwt.2010.1788.

CrossRef - SUMINO H, TAKAHASHI M, YAMAGUCHI T, et al. Feasibility study of a pilot-scale sewage treatment system combining an up-flow anaerobic sludge blanket (UASB) and an aerated fixed bed (AFB) reactor at ambient temperature. Bioresour Technol. 2007;98(1):177-182. doi:10.1016/j.biortech.2005.10.020.

CrossRef - Ali A, Zahid R, Ahmad A, Lew B. Sustainable Post Treatment Options of Anaerobic Effluent. In: Biodegradation - Engineering and Technology. InTech; 2013:191-221. doi:10.5772/56097.

CrossRef - Tawfik A, El-Gohary F, Temmink H. Treatment of domestic wastewater in an up-flow anaerobic sludge blanket reactor followed by moving bed biofilm reactor. Bioprocess Biosyst Eng. 2010;33:267-276. doi:10.1007/s00449-009-0321-1.

CrossRef - Vashi NV, Shah NC, Desai KR. Performance of UASB Post Treatment Technologies for Sewage Treatment in Surat City. Orient J Chem. 2019;35(4):1352-1359. doi:10.13005/ojc/350415.

CrossRef - K. Jaya Prakash, V.K. Tyagi, A.A. Kazmi and AK. Post-Treatment of UASB Reactor Effluent by Coagulation and Flocculation Process. Environ Prog. 2007;26(2):164-168. doi:DOI 10.1002/ep.10192.

CrossRef - Takahashi M, Yamaguchi T, Kuramoto Y, et al. Performance of a pilot-scale sewage treatment: An up-flow anaerobic sludge blanket (UASB) and a down-flow hanging sponge (DHS) reactors combined system by sulfur-redox reaction process under low-temperature conditions. Bioresour Technol. 2011;102(2):753-757. doi:10.1016/j.biortech.2010.08.081.

CrossRef - Hatamoto M, Ohtsuki K, Maharjan N, et al. Performance evaluation of the sulfur-redox-reaction–activated up-flow anaerobic sludge blanket and down-flow hanging sponge anaerobic/anoxic sequencing batch reactor system for municipal sewage treatment. Bioresour Technol. 2016;204:171-176. doi:10.1016/j.biortech.2015.12.052.

CrossRef - El-Kamah H, Mahmoud M, Tawfik A. Performance of down-flow hanging sponge (DHS) reactor coupled with up-flow anaerobic sludge blanket (UASB) reactor for treatment of onion dehydration wastewater. Bioresour Technol. 2011;102(14):7029-7035. doi:10.1016/j.biortech.2011.04.017.

CrossRef - Ismail S, Nasr M, Abdelrazek E, et al. Techno-economic feasibility of energy-saving self-aerated sponge tower combined with up-flow anaerobic sludge blanket reactor for treatment of hazardous landfill leachate. J Water Process Eng. 2020;37(April):101415. doi:10.1016/j.jwpe.2020.101415.

CrossRef - Kumar V, Ali A, Kazmi AA, Mehrotra I, Chopra AK. Slow sand filtration of UASB reactor ef luent : A promising post treatment technique. DES. 2009;249(2):571-576. doi:10.1016/j.desal.2008.12.049.

CrossRef - Ozgun H, Ersahin ME, Zhou Z, Tao Y, Spanjers H, van Lier JB. Comparative evaluation of the sludge characteristics along the height of upflow anaerobic sludge blanket coupled ultrafiltration systems. Biomass and Bioenergy. 2019;125(April):114-122. doi:10.1016/j.biombioe.2019.04.001.

CrossRef - Ozgun H, Tao Y, Ersahin ME, et al. Impact of temperature on feed-flow characteristics and filtration performance of an upflow anaerobic sludge blanket coupled ultrafiltration membrane treating municipal wastewater. Water Res. 2015;83:71-83. doi:10.1016/j.watres.2015.06.035.

CrossRef - Makwana AR, Ahammed MM. Continuous electrocoagulation process for the post-treatment of anaerobically treated municipal wastewater. Process Saf Environ Prot. 2016;102:724-733. doi:10.1016/j.psep.2016.06.005.

CrossRef - Banu JR, Sokkanathan G, Sharmila VG, Tamilarasan K, Kumar SA, Jamal MT. Combinative treatment of chocolaterie wastewater by a hybrid up-flow anaerobic sludge blanket reactor and solar photo Fenton process. Desalin WATER Treat. 2018;121(May):343-350. doi:10.5004/dwt.2018.22542.

CrossRef - Paschal C, Gastory L, Katima JHY, Njau KN. Application of up-flow anaerobic sludge blanket reactor integrated with constructed wetland for treatment of banana winery effluent. Water Pract Technol. 2017;12(3):667-674. doi:10.2166/wpt.2017.062.

CrossRef - Singh S, Singh S, Lo S-L, Kumar N, Kazmi AA, Fakour H. Preparation and reuse of iron and aluminum oxides activated sewage sludge based coagulants for the post-treatment of up-flow anaerobic sludge blanket reactor effluent. J Clean Prod. 2017;149:1020-1032. doi:10.1016/j.jclepro.2017.02.130.

CrossRef - Nair AT, Ahammed MM. The reuse of water treatment sludge as a coagulant for post-treatment of UASB reactor treating urban wastewater. J Clean Prod. 2015;96:272-281. doi:10.1016/j.jclepro.2013.12.037.

CrossRef - Chatterjee P, Ghangrekar MM, Rao S. Organic matter and nitrogen removal in a hybrid upflow anaerobic sludge blanket - Moving bed biofilm and rope bed biofilm reactor. J Environ Chem Eng. 2016;4(3):3240-3245. doi:10.1016/j.jece.2016.07.002.

CrossRef - Abou-Elela SI, Hellal MS, Harb AH. Assessment of seasonal variations on the performance of P-UASB/BAF for municipal wastewater treatment. Desalin Water Treat. 2015;57(36):1-8. doi:10.1080/19443994.2015.1103308.

CrossRef - Chatterjee P, Ghangrekar MM. Biomass granulation in an upflow anaerobic sludge blanket reactor treating 500 m3/day low-strength sewage and post treatment in high-rate algal pond. Water Sci Technol. 2017;76(5):1234-1242. doi:10.2166/wst.2017.269.

CrossRef - Kapsalis VC, Kyriakopoulos GL, Aravossis KG. Investigation of ecosystem services and circular economy interactions under an inter-organizational framework. Energies. 2019;12(9). doi:10.3390/en12091734.

CrossRef - Kyriakopoulos GL, Kapsalis VC, Aravossis KG, Zamparas M, Mitsikas A. Evaluating circular economy under a multi-parametric approach: A technological review. Sustain. 2019;11(21):1-24. doi:10.3390/su11216139.

CrossRef - Aravossis KG, Kapsalis VC, Kyriakopoulos GL, Xouleis TG. Development of a Holistic Assessment Framework for Industrial Organizations. Sustainability. 2019;11(14):3946. doi:10.3390/su11143946.

CrossRef